Acrylic tubes offer superior clarity and UV resistance compared to polypropylene tubes, making them ideal for applications requiring high transparency and durability. While polypropylene tubes provide better chemical resistance and flexibility, they are less rigid and prone to scratching. Choosing between acrylic and polypropylene tubes depends on the specific needs for clarity, strength, and chemical exposure.

Table of Comparison

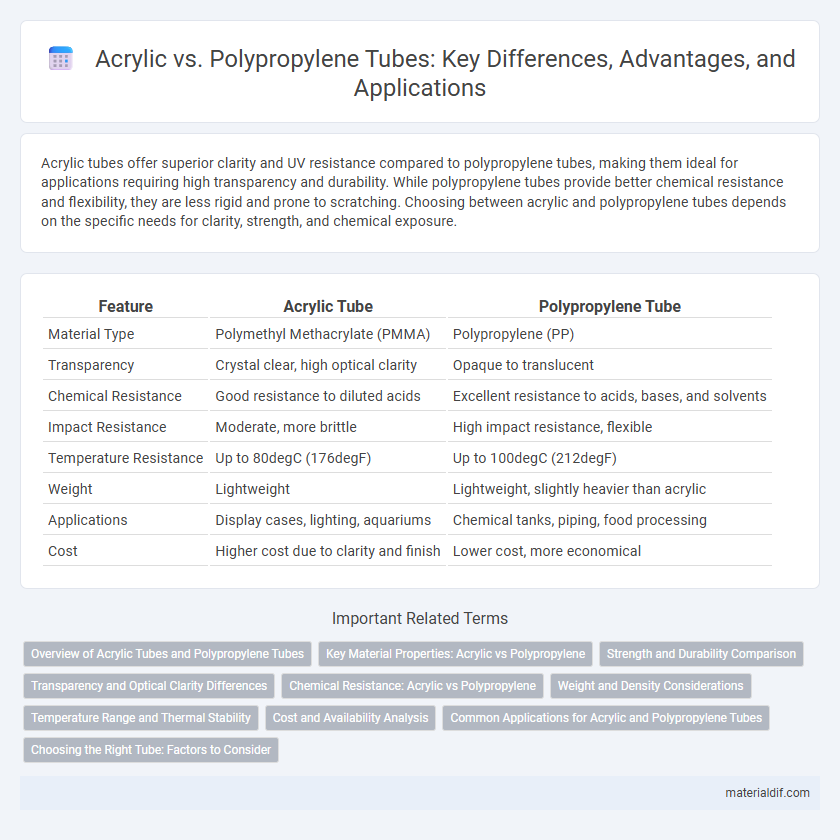

| Feature | Acrylic Tube | Polypropylene Tube |

|---|---|---|

| Material Type | Polymethyl Methacrylate (PMMA) | Polypropylene (PP) |

| Transparency | Crystal clear, high optical clarity | Opaque to translucent |

| Chemical Resistance | Good resistance to diluted acids | Excellent resistance to acids, bases, and solvents |

| Impact Resistance | Moderate, more brittle | High impact resistance, flexible |

| Temperature Resistance | Up to 80degC (176degF) | Up to 100degC (212degF) |

| Weight | Lightweight | Lightweight, slightly heavier than acrylic |

| Applications | Display cases, lighting, aquariums | Chemical tanks, piping, food processing |

| Cost | Higher cost due to clarity and finish | Lower cost, more economical |

Overview of Acrylic Tubes and Polypropylene Tubes

Acrylic tubes offer high transparency, excellent UV resistance, and superior rigidity, making them ideal for decorative and display applications, while polypropylene tubes are valued for their chemical resistance, flexibility, and durability in industrial and laboratory settings. Acrylic tubes maintain clarity and resist weathering, whereas polypropylene tubes excel in handling corrosive substances and exhibit significant impact resistance. The choice between acrylic and polypropylene tubes depends on application needs, such as optical clarity versus chemical and impact resistance.

Key Material Properties: Acrylic vs Polypropylene

Acrylic tubes offer excellent clarity and UV resistance, making them ideal for applications requiring transparency and outdoor durability, while polypropylene tubes provide superior chemical resistance and flexibility, suitable for handling aggressive solvents and impact-prone environments. Acrylic has higher rigidity and scratch resistance but lower impact strength compared to polypropylene, which is more resilient under stress but less transparent. Temperature tolerance also differs, with acrylic tubes performing well up to 80degC and polypropylene tubes withstanding up to 100degC, influencing material choice based on environmental conditions.

Strength and Durability Comparison

Acrylic tubes exhibit higher tensile strength and impact resistance compared to polypropylene tubes, making them more suitable for applications requiring rigidity and toughness. Polypropylene tubes offer superior chemical resistance and flexibility but tend to scratch and crack under heavy mechanical stress, reducing their durability. The inherent hardness of acrylic ensures longer-lasting structural integrity in demanding environments, while polypropylene's resilience suits dynamic applications with frequent bending.

Transparency and Optical Clarity Differences

Acrylic tubes exhibit superior transparency with light transmittance reaching up to 92%, making them ideal for applications requiring clear visibility and high optical clarity. In contrast, polypropylene tubes typically have lower transparency, with light transmittance around 80%, often appearing more opaque or cloudy. The enhanced optical clarity of acrylic tubes ensures minimal distortion and better color brilliance, which is critical in display and lighting applications.

Chemical Resistance: Acrylic vs Polypropylene

Acrylic tubes exhibit moderate chemical resistance, performing well against dilute acids and alkalis but degrading when exposed to strong solvents and concentrated acids. Polypropylene tubes offer superior chemical resistance, with excellent durability against a wide range of harsh chemicals including strong acids, bases, and solvents. When selecting tubing for chemical applications, polypropylene is preferred for environments requiring high resistance to aggressive substances, whereas acrylic suits less severe chemical conditions.

Weight and Density Considerations

Acrylic tubes have a density of approximately 1.18 g/cm3, making them heavier than polypropylene tubes, which have a density around 0.90 g/cm3. This difference in density means acrylic tubes offer greater rigidity but increase the overall weight of applications, while polypropylene tubes provide lighter solutions with enhanced flexibility. Selecting between acrylic and polypropylene tubes depends on the balance required between weight constraints and structural durability in specific projects.

Temperature Range and Thermal Stability

Acrylic tubes typically withstand temperatures up to 80degC with moderate thermal stability, making them suitable for applications requiring clarity and rigidity under mild heat. Polypropylene tubes offer a broader temperature range, tolerating from -20degC to 100degC, with superior thermal stability that resists deformation and chemical degradation under higher heat. Choosing between these materials depends on the specific temperature demands and thermal endurance required for the application.

Cost and Availability Analysis

Acrylic tubes generally cost more than polypropylene tubes due to their superior clarity and rigidity, making them ideal for display and aesthetic applications. Polypropylene tubes offer greater affordability and widespread availability, favored for chemical resistance and durability in industrial uses. Supply chains for polypropylene are more established globally, ensuring easier procurement compared to acrylic tubes, which may have limited suppliers.

Common Applications for Acrylic and Polypropylene Tubes

Acrylic tubes are widely used in display cases, aquariums, and signage due to their clarity, UV resistance, and ease of fabrication, making them ideal for aesthetic and visual applications. Polypropylene tubes excel in chemical processing, fluid transport, and laboratory equipment because of their excellent chemical resistance, durability, and low cost. Both materials are chosen based on the specific environmental exposure and mechanical requirements of industrial, commercial, and scientific applications.

Choosing the Right Tube: Factors to Consider

Acrylic tubes offer superior clarity, UV resistance, and rigidity, making them ideal for display and decorative applications, while polypropylene tubes excel in chemical resistance and flexibility, suited for industrial and laboratory use. Consider factors such as transparency requirements, exposure to chemicals or sunlight, mechanical stress, and temperature tolerance when selecting between acrylic and polypropylene tubes. Evaluating the specific environmental conditions and functional needs ensures optimal performance and longevity of the tubing material.

Acrylic Tube vs Polypropylene Tube Infographic

materialdif.com

materialdif.com