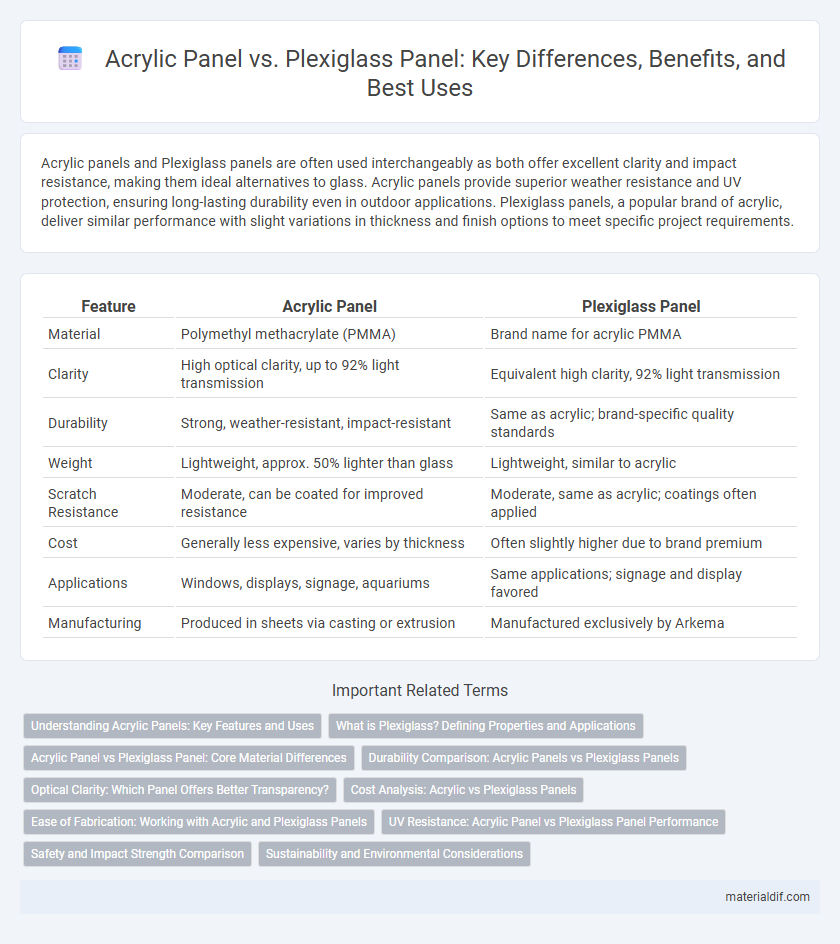

Acrylic panels and Plexiglass panels are often used interchangeably as both offer excellent clarity and impact resistance, making them ideal alternatives to glass. Acrylic panels provide superior weather resistance and UV protection, ensuring long-lasting durability even in outdoor applications. Plexiglass panels, a popular brand of acrylic, deliver similar performance with slight variations in thickness and finish options to meet specific project requirements.

Table of Comparison

| Feature | Acrylic Panel | Plexiglass Panel |

|---|---|---|

| Material | Polymethyl methacrylate (PMMA) | Brand name for acrylic PMMA |

| Clarity | High optical clarity, up to 92% light transmission | Equivalent high clarity, 92% light transmission |

| Durability | Strong, weather-resistant, impact-resistant | Same as acrylic; brand-specific quality standards |

| Weight | Lightweight, approx. 50% lighter than glass | Lightweight, similar to acrylic |

| Scratch Resistance | Moderate, can be coated for improved resistance | Moderate, same as acrylic; coatings often applied |

| Cost | Generally less expensive, varies by thickness | Often slightly higher due to brand premium |

| Applications | Windows, displays, signage, aquariums | Same applications; signage and display favored |

| Manufacturing | Produced in sheets via casting or extrusion | Manufactured exclusively by Arkema |

Understanding Acrylic Panels: Key Features and Uses

Acrylic panels, often compared to plexiglass panels, are made from polymethyl methacrylate (PMMA) offering superior clarity, UV resistance, and impact strength. These panels are commonly used in signage, glazing, and protective barriers due to their lightweight nature and easy fabrication compared to glass. Understanding the differences highlights acrylic panels' advantages in durability, optical quality, and versatility across architectural and industrial applications.

What is Plexiglass? Defining Properties and Applications

Plexiglass, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic often used as a lightweight and shatter-resistant alternative to glass. It offers high optical clarity, UV resistance, and excellent weatherability, making it ideal for applications such as windows, signage, aquariums, and protective barriers. Plexiglass panels are prized for their ease of fabrication, resistance to impact, and ability to withstand outdoor conditions without yellowing.

Acrylic Panel vs Plexiglass Panel: Core Material Differences

Acrylic panels and Plexiglass panels are often considered interchangeable, but their core material differences impact performance and application. Acrylic panels are made from polymethyl methacrylate (PMMA), offering higher clarity and UV resistance, while Plexiglass is a branded form of PMMA with slight variations in manufacturing that may affect durability and cost. Understanding these material distinctions ensures appropriate selection for projects demanding specific optical qualities and weather resistance.

Durability Comparison: Acrylic Panels vs Plexiglass Panels

Acrylic panels and plexiglass panels share the same chemical composition, making their durability nearly identical, with both offering excellent resistance to impact and weathering compared to glass. Acrylic panels typically resist UV damage better, maintaining clarity and strength over prolonged outdoor exposure without yellowing or becoming brittle. Plexiglass, a brand name often used interchangeably with acrylic, performs equally well in scratch resistance and overall toughness, establishing them as top choices for long-lasting transparent and protective surfaces.

Optical Clarity: Which Panel Offers Better Transparency?

Acrylic panels and plexiglass panels are often used interchangeably since both refer to polymethyl methacrylate (PMMA), a material known for exceptional optical clarity. Both panels provide superior transparency with light transmittance around 92%, making them clearer than glass in many applications. Differences in clarity are minimal, but the manufacturing process of plexiglass sometimes results in a slightly smoother surface that can enhance visual clarity in high-precision projects.

Cost Analysis: Acrylic vs Plexiglass Panels

Acrylic panels generally offer a more cost-effective solution compared to plexiglass panels due to lower raw material and manufacturing expenses. Plexiglass panels, often made from higher-grade polymethyl methacrylate (PMMA), tend to have a higher price point but provide enhanced durability and clarity. When analyzing costs, acrylic panels are ideal for budget-conscious projects, while plexiglass justifies its premium price in applications requiring superior strength and optical quality.

Ease of Fabrication: Working with Acrylic and Plexiglass Panels

Acrylic panels offer superior ease of fabrication due to their excellent thermoforming properties and ability to be easily cut, drilled, and polished without cracking. Plexiglass panels, a brand of acrylic, provide similar workability but may vary slightly in hardness and thickness options, affecting machining ease. Both materials allow precision shaping and customization, making them ideal for complex designs in signage, displays, and protective barriers.

UV Resistance: Acrylic Panel vs Plexiglass Panel Performance

Acrylic panels offer superior UV resistance compared to plexiglass panels, maintaining clarity and structural integrity under prolonged sun exposure. High-grade acrylic contains UV inhibitors that prevent yellowing and degradation, ensuring long-term durability for outdoor applications. Plexiglass panels may exhibit reduced UV stability over time, making acrylic the preferred choice for environments with intense or continuous UV exposure.

Safety and Impact Strength Comparison

Acrylic panels offer superior impact strength compared to plexiglass panels, making them a safer choice for environments requiring high durability. Acrylic has a tensile strength of approximately 75 MPa, which is significantly higher than standard plexiglass, reducing the risk of cracking or shattering under stress. Its enhanced safety properties make acrylic panels ideal for use in protective barriers, glazing, and other applications where impact resistance is critical.

Sustainability and Environmental Considerations

Acrylic panels, made from polymethyl methacrylate (PMMA), offer superior recyclability compared to traditional plexiglass panels, which often contain additives that hinder eco-friendly disposal. The production of acrylic panels involves less energy consumption and emits fewer greenhouse gases than plexiglass manufacturing processes, contributing to a lower carbon footprint. Choosing acrylic panels supports sustainability goals by promoting material reuse and reducing environmental pollution.

Acrylic Panel vs Plexiglass Panel Infographic

materialdif.com

materialdif.com