Acrylic laser cutting offers precise, smooth edges and intricate detailing with faster processing times compared to CNC milling, which is better suited for thicker materials and three-dimensional shaping. Laser cutting uses a focused beam to vaporize material cleanly, minimizing waste and reducing heat distortion, while CNC milling removes material mechanically, potentially leaving rougher surfaces that require finishing. Choosing between the two depends on the complexity of the design, thickness of the acrylic, and desired finish quality.

Table of Comparison

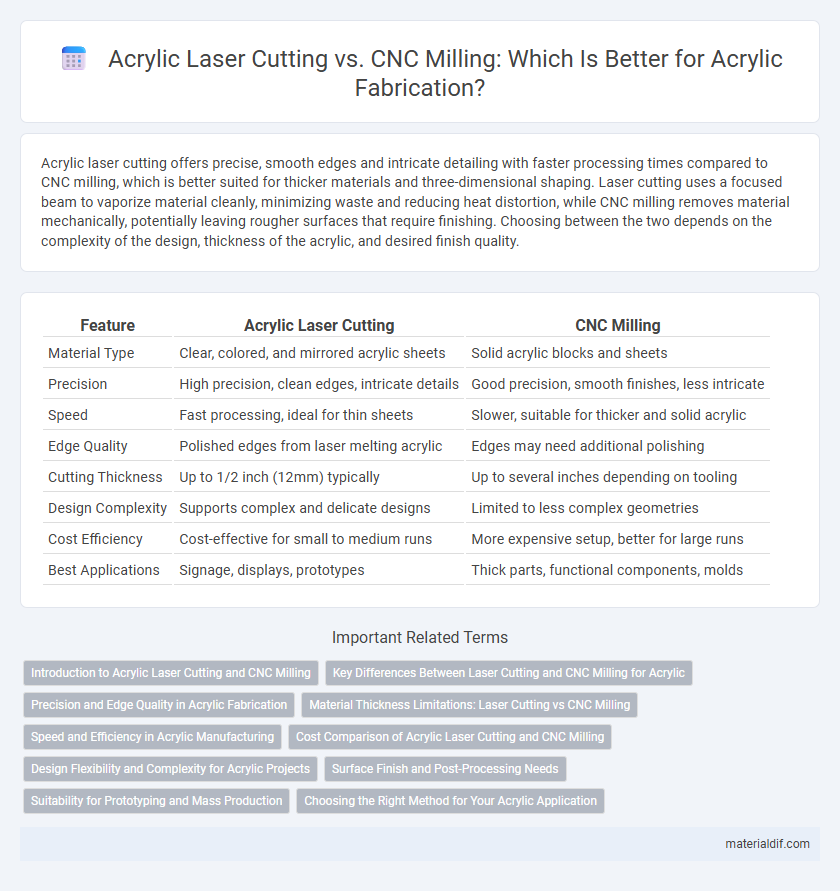

| Feature | Acrylic Laser Cutting | CNC Milling |

|---|---|---|

| Material Type | Clear, colored, and mirrored acrylic sheets | Solid acrylic blocks and sheets |

| Precision | High precision, clean edges, intricate details | Good precision, smooth finishes, less intricate |

| Speed | Fast processing, ideal for thin sheets | Slower, suitable for thicker and solid acrylic |

| Edge Quality | Polished edges from laser melting acrylic | Edges may need additional polishing |

| Cutting Thickness | Up to 1/2 inch (12mm) typically | Up to several inches depending on tooling |

| Design Complexity | Supports complex and delicate designs | Limited to less complex geometries |

| Cost Efficiency | Cost-effective for small to medium runs | More expensive setup, better for large runs |

| Best Applications | Signage, displays, prototypes | Thick parts, functional components, molds |

Introduction to Acrylic Laser Cutting and CNC Milling

Acrylic laser cutting utilizes a high-powered laser beam to precisely cut and engrave acrylic sheets, offering smooth edges and intricate detail with minimal material waste. CNC milling involves a rotating cutting tool that machines acrylic by removing material layer by layer, providing greater control over depth and thickness variations. Both methods cater to different design requirements, with laser cutting excelling in speed and fine detail, while CNC milling offers robust three-dimensional shaping capabilities.

Key Differences Between Laser Cutting and CNC Milling for Acrylic

Laser cutting acrylic uses a focused laser beam to precisely melt and vaporize material, resulting in clean edges and intricate designs with minimal material distortion. CNC milling removes acrylic by mechanically cutting and grinding with rotary tools, producing thicker cuts and deeper engravings but often creating rougher edges. Laser cutting is ideal for delicate, detailed work and faster production, while CNC milling suits thicker acrylic and three-dimensional shapes requiring precise depth control.

Precision and Edge Quality in Acrylic Fabrication

Acrylic laser cutting delivers superior precision with minimal thermal distortion, achieving intricate designs and smooth, polished edges ideal for high-detail applications. CNC milling offers robust material removal but may produce rougher edges requiring post-processing to match laser-cut clarity. The choice between laser cutting and CNC milling hinges on the desired edge quality and the complexity of acrylic fabrication projects.

Material Thickness Limitations: Laser Cutting vs CNC Milling

Acrylic laser cutting is ideal for thinner sheets, typically up to 1/2 inch thick, due to its precision and ability to create smooth edges without mechanical stress. CNC milling, however, handles thicker acrylic materials more effectively, often exceeding 1 inch in thickness, but may produce rougher edges requiring post-processing. Selecting the optimal method depends on the acrylic's thickness and the desired finish quality.

Speed and Efficiency in Acrylic Manufacturing

Acrylic laser cutting offers faster processing speeds compared to CNC milling due to its precise, non-contact method that reduces material stress and tool wear. CNC milling, while versatile for complex shapes, is generally slower because it requires physical tool engagement and multiple passes. For high-volume acrylic manufacturing, laser cutting improves efficiency by minimizing setup time and delivering consistent, clean cuts with minimal post-processing.

Cost Comparison of Acrylic Laser Cutting and CNC Milling

Acrylic laser cutting generally offers lower upfront costs and faster processing times compared to CNC milling, making it more cost-effective for intricate designs and small to medium production runs. CNC milling involves higher equipment and tooling expenses, plus longer setup times, which increase the overall cost, especially for complex shapes or thicker acrylic sheets. When evaluating cost efficiency, laser cutting is preferred for precision and speed, while CNC milling is suited for heavy-duty applications requiring deeper cuts and robust finishes.

Design Flexibility and Complexity for Acrylic Projects

Acrylic laser cutting offers superior design flexibility and precision for intricate, detailed patterns, enabling sharp edges and complex shapes unattainable with CNC milling. CNC milling excels in creating thicker acrylic components with smooth finishes and three-dimensional contours but struggles with fine, delicate designs due to tool size limitations. For acrylic projects demanding high complexity and detailed customization, laser cutting provides unmatched accuracy and versatility.

Surface Finish and Post-Processing Needs

Acrylic laser cutting delivers smooth, polished edges with a glossy finish, minimizing the need for extensive post-processing compared to CNC milling, which often leaves tool marks requiring sanding or polishing. Laser-cut acrylic also reduces the risk of melting or chipping, preserving surface integrity better than the mechanical action of CNC milling. For applications demanding clean aesthetics and time-efficient finishing, laser cutting of acrylic is generally preferred over CNC milling.

Suitability for Prototyping and Mass Production

Acrylic laser cutting offers high precision and clean edges, making it ideal for rapid prototyping and intricate designs with minimal material waste. CNC milling provides greater versatility for thicker acrylic sheets and complex 3D shapes, suitable for both low-volume prototyping and customized mass production. For large-scale manufacturing, laser cutting's speed and efficiency often outperform CNC milling, enhancing production timelines and cost-effectiveness.

Choosing the Right Method for Your Acrylic Application

Acrylic laser cutting offers precision and clean edges ideal for intricate designs and detailed signage, while CNC milling excels in creating complex three-dimensional shapes and deeper engravings suited for thicker acrylic sheets. Selecting the right method depends on the project's complexity, desired finish quality, and acrylic thickness; laser cutting is faster for thin acrylic, whereas CNC milling provides versatility for more robust materials. Understanding these differences ensures optimal results and efficient use of production resources.

Acrylic Laser Cutting vs CNC Milling Infographic

materialdif.com

materialdif.com