Acrylic bonding involves using specialized adhesives to join acrylic pieces, providing a clear and strong bond ideal for aesthetic applications. Acrylic welding uses heat or solvents to fuse surfaces, creating a more durable and seamless joint often preferred for structural integrity. Choosing between bonding and welding depends on the required strength, appearance, and application of the acrylic product.

Table of Comparison

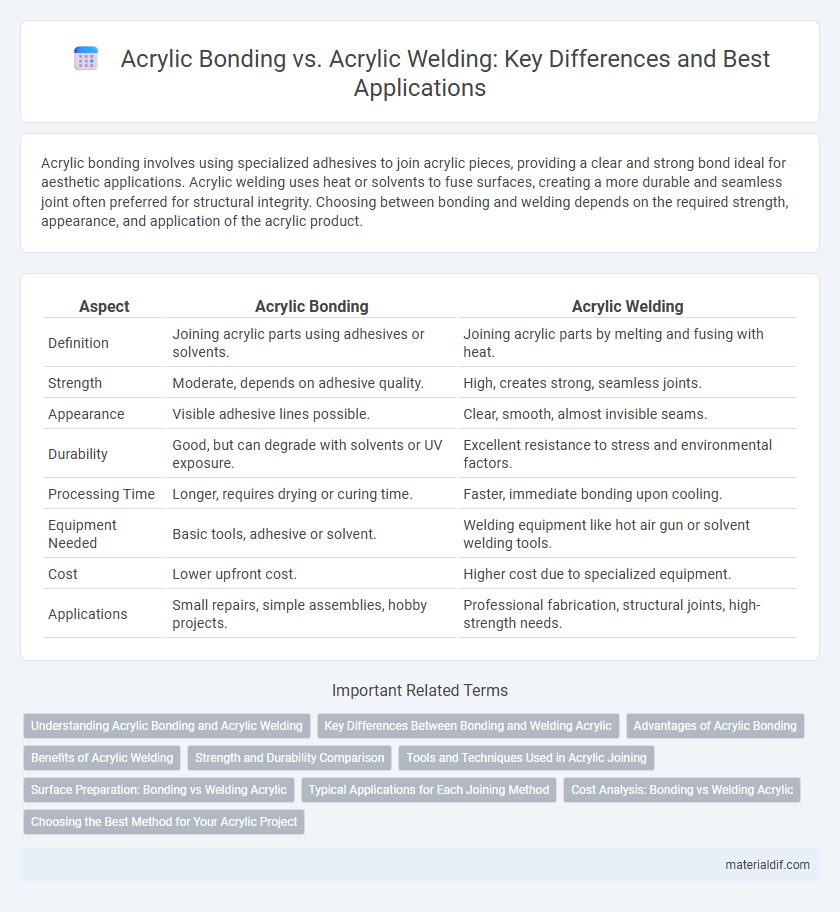

| Aspect | Acrylic Bonding | Acrylic Welding |

|---|---|---|

| Definition | Joining acrylic parts using adhesives or solvents. | Joining acrylic parts by melting and fusing with heat. |

| Strength | Moderate, depends on adhesive quality. | High, creates strong, seamless joints. |

| Appearance | Visible adhesive lines possible. | Clear, smooth, almost invisible seams. |

| Durability | Good, but can degrade with solvents or UV exposure. | Excellent resistance to stress and environmental factors. |

| Processing Time | Longer, requires drying or curing time. | Faster, immediate bonding upon cooling. |

| Equipment Needed | Basic tools, adhesive or solvent. | Welding equipment like hot air gun or solvent welding tools. |

| Cost | Lower upfront cost. | Higher cost due to specialized equipment. |

| Applications | Small repairs, simple assemblies, hobby projects. | Professional fabrication, structural joints, high-strength needs. |

Understanding Acrylic Bonding and Acrylic Welding

Acrylic bonding involves using specialized adhesives to join acrylic sheets, creating strong, clear seams ideal for decorative or display purposes. Acrylic welding uses heat or solvents to melt and fuse the edges of acrylic pieces, resulting in a more durable, permanent joint suitable for structural applications. Understanding the differences in strength, clarity, and application methods is critical for selecting the appropriate technique in acrylic fabrication projects.

Key Differences Between Bonding and Welding Acrylic

Acrylic bonding uses adhesives such as solvents or glues to join acrylic pieces, creating a chemical bond without melting the material, which allows for clear, smooth seams ideal for display cases and signs. Acrylic welding employs heat or ultrasonic energy to melt the edges of acrylic sheets, fusing them together to form a stronger, more durable joint suited for structural applications. Bonding offers easier application and less equipment, while welding provides superior strength and resistance to environmental factors.

Advantages of Acrylic Bonding

Acrylic bonding offers superior clarity and seamless joints without the risk of heat distortion, making it ideal for precision applications. It enables strong, durable adhesion using solvent-based adhesives that chemically fuse surfaces, preserving the material's optical properties. This method is cost-effective and versatile, accommodating complex shapes and delicate acrylic components without compromising structural integrity.

Benefits of Acrylic Welding

Acrylic welding offers superior strength and durability compared to acrylic bonding, creating seamless joints that are less prone to cracking or weakening over time. The process melts the acrylic surfaces together, resulting in a clear, polished finish with enhanced structural integrity and resistance to environmental factors such as moisture and UV exposure. This makes acrylic welding ideal for industrial applications requiring long-lasting, high-performance connections.

Strength and Durability Comparison

Acrylic bonding uses adhesives like solvent cements to chemically fuse materials, offering strong joints ideal for moderate stress applications, while acrylic welding melts the base material to create a single, continuous piece, resulting in superior strength and durability. Welding provides enhanced resistance to impact, environmental factors, and mechanical stress compared to bonded joints, making it preferable for structural or load-bearing applications. The choice between bonding and welding hinges on required joint performance, with welding generally delivering greater longevity and robustness in demanding conditions.

Tools and Techniques Used in Acrylic Joining

Acrylic bonding involves using solvents like dichloromethane or methyl methacrylate, applied with precision brushes or syringes to chemically fuse acrylic surfaces, resulting in a clear, strong joint ideal for detailed or artistic projects. Acrylic welding employs specialized hot air guns or ultrasonic welding machines to melt and join acrylic edges through controlled heat and pressure, producing robust, seamless bonds suited for industrial applications or thicker acrylic sheets. Both techniques demand specific tools tailored to the intended acrylic thickness and project requirements, ensuring optimal bond strength and surface finish.

Surface Preparation: Bonding vs Welding Acrylic

Surface preparation for acrylic bonding involves thorough cleaning and priming to ensure optimal adhesive adhesion, focusing on removing oils, dust, and moisture to create a chemically receptive surface. Acrylic welding requires sanding or vapor polishing the edges to be joined, enabling molecular fusion by softening the acrylic for a seamless bond. Proper surface prep in bonding enhances mechanical grip, while in welding, it ensures plastic fusion without gaps or weak points.

Typical Applications for Each Joining Method

Acrylic bonding is commonly used in applications requiring optical clarity and chemical resistance, such as display cases, aquariums, and signage, where a strong, transparent joint is essential. Acrylic welding suits structural applications like fabrication of large tanks, protective barriers, and automotive components, providing robust, stress-resistant seams. Each joining method offers advantages tailored to specific industry needs, emphasizing either aesthetic quality or mechanical strength.

Cost Analysis: Bonding vs Welding Acrylic

Cost analysis between acrylic bonding and acrylic welding reveals distinct financial implications based on project scale and precision requirements. Acrylic bonding generally incurs lower initial setup costs with adhesive materials priced affordably and no need for specialized equipment, making it cost-effective for small to medium projects. In contrast, acrylic welding demands investment in welding machines and skilled labor, but it provides stronger joints and reduced long-term maintenance, offsetting higher upfront expenses in large-scale or high-stress applications.

Choosing the Best Method for Your Acrylic Project

Acrylic bonding involves using solvents or adhesives to fuse acrylic pieces, offering precision and ease for delicate or complex shapes. Acrylic welding uses heat to melt and join the material, creating a strong, seamless bond ideal for structural applications or high-stress environments. Selecting the best method depends on factors like the required bond strength, project complexity, and equipment availability, with bonding suited for detailed work and welding favored for durability.

Acrylic Bonding vs Acrylic Welding Infographic

materialdif.com

materialdif.com