Acrylic resin offers superior UV resistance and clarity compared to epoxy resin, making it ideal for outdoor displays and applications requiring long-lasting transparency. While epoxy resin provides excellent adhesion and chemical resistance, acrylic resin cures faster and maintains color stability over time. Choosing between acrylic resin and epoxy resin depends on the specific needs for durability, clarity, and exposure conditions in your project.

Table of Comparison

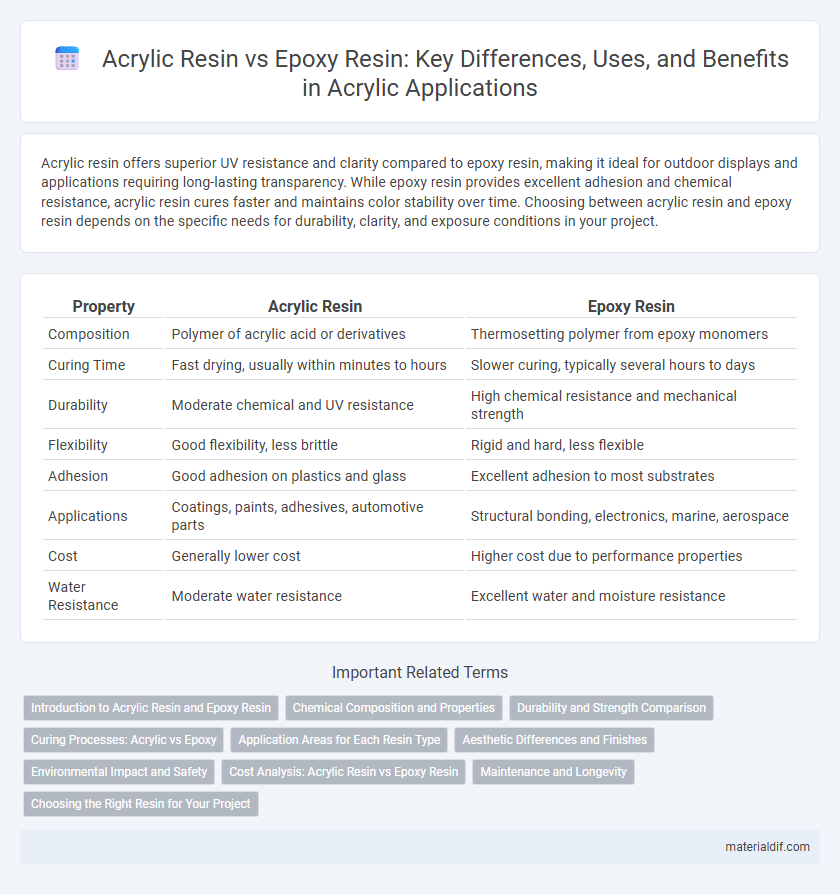

| Property | Acrylic Resin | Epoxy Resin |

|---|---|---|

| Composition | Polymer of acrylic acid or derivatives | Thermosetting polymer from epoxy monomers |

| Curing Time | Fast drying, usually within minutes to hours | Slower curing, typically several hours to days |

| Durability | Moderate chemical and UV resistance | High chemical resistance and mechanical strength |

| Flexibility | Good flexibility, less brittle | Rigid and hard, less flexible |

| Adhesion | Good adhesion on plastics and glass | Excellent adhesion to most substrates |

| Applications | Coatings, paints, adhesives, automotive parts | Structural bonding, electronics, marine, aerospace |

| Cost | Generally lower cost | Higher cost due to performance properties |

| Water Resistance | Moderate water resistance | Excellent water and moisture resistance |

Introduction to Acrylic Resin and Epoxy Resin

Acrylic resin is a versatile synthetic polymer known for its clarity, flexibility, and resistance to UV light, commonly used in coatings, adhesives, and 3D printing. Epoxy resin is a thermosetting polymer prized for its exceptional mechanical strength, chemical resistance, and strong adhesive properties, widely applied in construction, electronics, and composites. Both resins serve distinct functions based on their curing methods and performance characteristics, making them suitable for different industrial and commercial applications.

Chemical Composition and Properties

Acrylic resin is primarily composed of polymethyl methacrylate (PMMA), known for its clarity, UV resistance, and flexibility, whereas epoxy resin consists of epoxide groups and hardeners that create a rigid, strong, and chemically resistant polymer matrix. Acrylic resin offers superior weatherability and better resistance to yellowing than epoxy, making it ideal for outdoor applications, while epoxy resin excels in mechanical strength and adhesive properties, making it suitable for structural bonding and coatings. Differences in curing processes reflect their chemical structures: acrylic resins cure through polymerization with initiators, whereas epoxies cure via a chemical reaction between epoxide and amine groups, influencing their durability and application range.

Durability and Strength Comparison

Acrylic resin offers high impact resistance and rapid curing time, making it durable for various applications but generally exhibits less mechanical strength compared to epoxy resin. Epoxy resin provides superior tensile strength, chemical resistance, and long-term durability, making it ideal for heavy-duty structural uses. For projects requiring maximum strength and longevity, epoxy resin outperforms acrylic resin in maintaining integrity under stress and environmental exposure.

Curing Processes: Acrylic vs Epoxy

Acrylic resin cures primarily through a polymerization process activated by heat or UV light, resulting in a faster and more controlled hardening time compared to epoxy resin. Epoxy resin cures via a chemical reaction between resin and hardener that occurs at room temperature, taking longer but offering superior adhesion and resistance to environmental factors. Understanding the distinct curing mechanisms is essential for selecting the proper resin based on project requirements such as speed, durability, and environmental exposure.

Application Areas for Each Resin Type

Acrylic resin is commonly used in automotive parts, displays, and optical devices due to its clarity, UV resistance, and weatherability, making it ideal for both indoor and outdoor applications. Epoxy resin excels in structural applications such as adhesives, coatings, and composite materials because of its superior mechanical strength, chemical resistance, and excellent bonding properties. While acrylic resin suits decorative and light-duty applications, epoxy resin is preferred in industrial, marine, and aerospace sectors for its durability and load-bearing capabilities.

Aesthetic Differences and Finishes

Acrylic resin offers high clarity and vibrant color options, producing smooth, glass-like finishes ideal for artistic and decorative applications, while epoxy resin provides a thicker, more glossy surface that enhances depth and durability. The aesthetic appeal of acrylic resin lies in its excellent resistance to yellowing and UV light, maintaining color fidelity over time, whereas epoxy resin tends to develop a warm amber tint with prolonged exposure. Both resins deliver unique textures, with acrylic favored for sharp, clean edges and epoxy prized for its self-leveling, high-gloss coatings that emphasize dimensionality.

Environmental Impact and Safety

Acrylic resin generally exhibits lower toxicity and emits fewer volatile organic compounds (VOCs) during curing compared to epoxy resin, making it a safer option for indoor use. Epoxy resin, while offering superior durability and chemical resistance, often contains bisphenol-A (BPA) and hardeners that can be harmful to both human health and the environment if not properly handled. Disposal of acrylic resin tends to have a smaller environmental footprint due to its faster biodegradability, whereas epoxy resin can persist longer in the environment, posing greater ecological risks.

Cost Analysis: Acrylic Resin vs Epoxy Resin

Acrylic resin typically costs less than epoxy resin, making it a more budget-friendly option for large-scale applications and projects with cost constraints. Epoxy resin offers superior durability and chemical resistance, but these benefits come with a higher price tag that can significantly impact overall project expenses. When evaluating materials, the choice between acrylic and epoxy resin should balance cost considerations with performance requirements to achieve optimal value.

Maintenance and Longevity

Acrylic resin offers superior UV resistance, reducing yellowing and degradation over time, which minimizes maintenance compared to epoxy resin. Epoxy resin tends to be more prone to discoloration and chalking when exposed to sunlight, requiring more frequent upkeep to preserve appearance and integrity. Longevity of acrylic resin in outdoor applications typically exceeds that of epoxy, making it a preferred choice for projects demanding long-term durability and low maintenance.

Choosing the Right Resin for Your Project

Acrylic resin offers superior UV resistance and faster curing times, making it ideal for outdoor and decorative projects where color stability and quick completion are priorities. Epoxy resin provides greater mechanical strength and chemical resistance, suited for structural applications and surfaces exposed to heavy wear or moisture. Selecting the right resin depends on project requirements such as exposure conditions, desired durability, and curing time.

Acrylic Resin vs Epoxy Resin Infographic

materialdif.com

materialdif.com