Acrylic engraving uses precise rotary or diamond tips to create detailed, tactile designs on the surface, offering depth and texture ideal for decorative purposes. Laser cutting employs high-powered lasers to slice through acrylic sheets with extreme accuracy, producing clean edges and complex shapes for structural applications. Both techniques enhance acrylic's versatility, but choosing between engraving and laser cutting depends on whether surface detail or precise shaping is the primary goal.

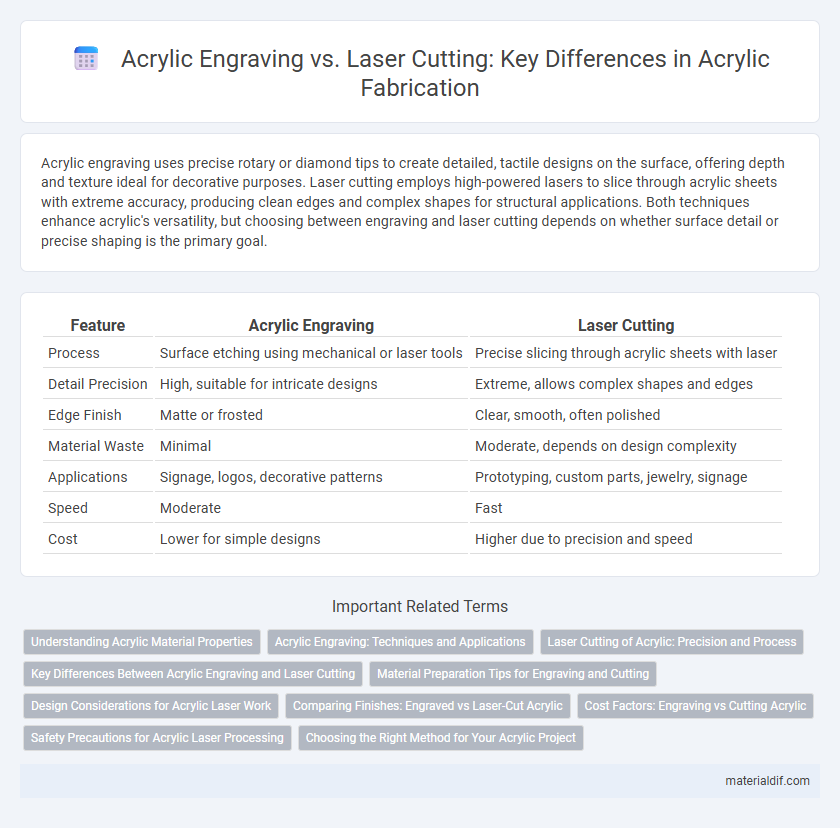

Table of Comparison

| Feature | Acrylic Engraving | Laser Cutting |

|---|---|---|

| Process | Surface etching using mechanical or laser tools | Precise slicing through acrylic sheets with laser |

| Detail Precision | High, suitable for intricate designs | Extreme, allows complex shapes and edges |

| Edge Finish | Matte or frosted | Clear, smooth, often polished |

| Material Waste | Minimal | Moderate, depends on design complexity |

| Applications | Signage, logos, decorative patterns | Prototyping, custom parts, jewelry, signage |

| Speed | Moderate | Fast |

| Cost | Lower for simple designs | Higher due to precision and speed |

Understanding Acrylic Material Properties

Acrylic engraving and laser cutting require a deep understanding of acrylic's thermal properties, such as its melting point of approximately 160degC and its sensitivity to heat, which affects edge quality and detail precision. Engraving allows for surface-level marking without compromising structural integrity, while laser cutting fully penetrates the material, necessitating precise control of laser power and speed to avoid melting or discoloration. Recognizing the balance between heat input and material response is essential for achieving optimal results in both acrylic engraving and laser cutting projects.

Acrylic Engraving: Techniques and Applications

Acrylic engraving employs mechanical or laser techniques to create detailed designs by removing surface layers, enhancing visual depth and texture. Common methods include rotary engraving, which carves precise patterns, and laser engraving, which offers fine detail with minimal material distortion. This technique is widely used in signage, decorative panels, and personalized gifts, maximizing acrylic's clarity and durability for intricate artistic applications.

Laser Cutting of Acrylic: Precision and Process

Laser cutting of acrylic offers unparalleled precision, enabling intricate designs with smooth edges and minimal material distortion. The process involves a high-powered CO2 laser that vaporizes the acrylic along the designated path, ensuring clean cuts ideal for detailed applications in signage, jewelry, and prototypes. This method outperforms traditional engraving by providing faster production rates and superior edge clarity, essential for professional-grade acrylic fabrication.

Key Differences Between Acrylic Engraving and Laser Cutting

Acrylic engraving involves etching or carving designs below the surface, creating a textured effect that highlights intricate details, whereas laser cutting precisely slices through the material to produce separate shapes or components. Engraving maintains the acrylic's structural integrity without full penetration, while laser cutting removes parts entirely, allowing for complex assemblies or three-dimensional projects. The choice between engraving and cutting depends on the desired visual impact, depth, and application of the acrylic piece.

Material Preparation Tips for Engraving and Cutting

For optimal acrylic engraving, ensure the material surface is clean and free of protective film to prevent residue buildup and achieve precise detailing. When preparing acrylic for laser cutting, select sheets with a uniform thickness and secure them firmly to avoid movement that can cause uneven edges or misalignment. Adjust laser power settings based on acrylic type and thickness to minimize melting and charring for cleaner cuts and sharper engravings.

Design Considerations for Acrylic Laser Work

Acrylic laser work demands careful design considerations such as maintaining appropriate line thickness and spacing to prevent melting or distortion during engraving and cutting. Vector elements must be optimized for clean cuts, while raster engraving requires precise control over laser power and speed to achieve detailed images without damaging the acrylic surface. Choosing the right acrylic type and color also influences the final outcome, ensuring clarity and contrast in both engraved and cut sections.

Comparing Finishes: Engraved vs Laser-Cut Acrylic

Engraved acrylic surfaces display detailed, frosted patterns that enhance texture and depth, while laser-cut acrylic produces smooth, clean edges with precise shapes. The engraving process removes a thin layer, creating a matte finish ideal for intricate designs, whereas laser cutting vaporizes material along the outline, offering sharp contours and glossy sidewalls. Choosing between engraved and laser-cut acrylic depends on whether the project prioritizes detailed surface artistry or precise dimensional cuts with polished edges.

Cost Factors: Engraving vs Cutting Acrylic

Acrylic engraving typically incurs lower initial costs due to slower machine wear and reduced energy consumption compared to laser cutting, which demands higher power and precision. Laser cutting acrylic involves substantial expenses for cleaner edges and intricate shapes, with costs influenced by material thickness and design complexity. Pricing for both processes varies based on equipment type, labor intensity, and production volume, making engraving generally more cost-effective for simpler projects.

Safety Precautions for Acrylic Laser Processing

Acrylic laser engraving and cutting require strict safety precautions to prevent hazardous fumes and fire risks from the material's combustion. Proper ventilation systems and fume extractors are essential to remove toxic gases like methyl methacrylate released during laser processing. Using appropriate protective gear and maintaining laser equipment regularly reduces the risk of accidents and ensures a safer acrylic machining environment.

Choosing the Right Method for Your Acrylic Project

Acrylic engraving uses precision tools to etch detailed designs onto the surface, offering fine texture and depth ideal for decorative elements and branding. Laser cutting provides clean, smooth edges and can create intricate shapes with high accuracy, perfect for complex components and signage. Selecting the right method depends on project requirements like detail level, edge finish, and production speed, ensuring the best balance between aesthetics and functionality.

Acrylic Engraving vs Laser Cutting Infographic

materialdif.com

materialdif.com