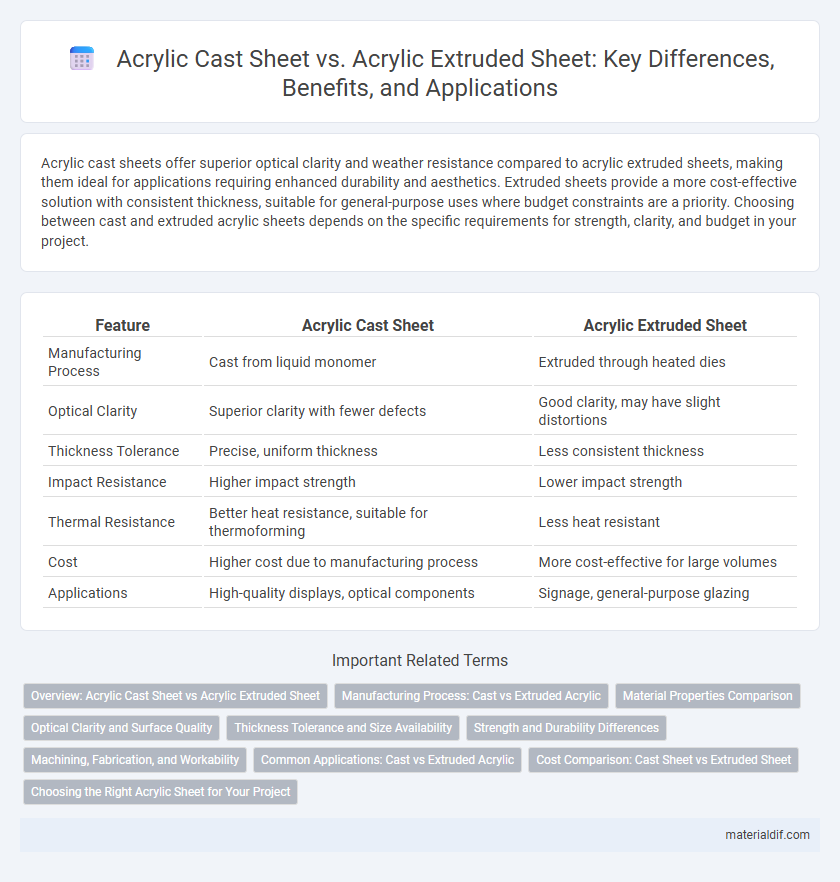

Acrylic cast sheets offer superior optical clarity and weather resistance compared to acrylic extruded sheets, making them ideal for applications requiring enhanced durability and aesthetics. Extruded sheets provide a more cost-effective solution with consistent thickness, suitable for general-purpose uses where budget constraints are a priority. Choosing between cast and extruded acrylic sheets depends on the specific requirements for strength, clarity, and budget in your project.

Table of Comparison

| Feature | Acrylic Cast Sheet | Acrylic Extruded Sheet |

|---|---|---|

| Manufacturing Process | Cast from liquid monomer | Extruded through heated dies |

| Optical Clarity | Superior clarity with fewer defects | Good clarity, may have slight distortions |

| Thickness Tolerance | Precise, uniform thickness | Less consistent thickness |

| Impact Resistance | Higher impact strength | Lower impact strength |

| Thermal Resistance | Better heat resistance, suitable for thermoforming | Less heat resistant |

| Cost | Higher cost due to manufacturing process | More cost-effective for large volumes |

| Applications | High-quality displays, optical components | Signage, general-purpose glazing |

Overview: Acrylic Cast Sheet vs Acrylic Extruded Sheet

Acrylic cast sheets are produced by pouring liquid acrylic into molds, resulting in higher molecular weight and superior optical clarity, making them ideal for demanding applications. Acrylic extruded sheets are made by continuously pushing molten acrylic through a die, offering cost-effective production with consistent thickness and easier fabrication. Cast sheets excel in strength and durability, while extruded sheets provide enhanced flexibility and affordability for general-purpose uses.

Manufacturing Process: Cast vs Extruded Acrylic

Cast acrylic sheets are produced by pouring liquid methyl methacrylate monomer into molds, where it polymerizes slowly, resulting in a dense, hard, and superior optical clarity material. Extruded acrylic sheets are created by continuously pushing melted acrylic resin through a die, producing sheets with more consistent thickness and better surface abrasion resistance but slightly lower optical quality. The slower polymerization in cast acrylic allows for higher molecular weight chains, enhancing chemical resistance and mechanical strength compared to the faster cooling extruded sheets.

Material Properties Comparison

Acrylic cast sheets exhibit superior optical clarity, higher chemical resistance, and better weatherability compared to acrylic extruded sheets, making them ideal for outdoor applications and glazing. Extruded acrylic sheets offer improved impact resistance and are more cost-effective, with consistent thickness and easier fabrication processes. Cast acrylic's enhanced durability and hardness result from its slower polymerization process, whereas extruded acrylic is produced through a continuous extrusion method, affecting its mechanical and thermal properties.

Optical Clarity and Surface Quality

Acrylic cast sheets exhibit superior optical clarity due to their manufacturing process, which results in fewer internal stresses and higher light transmission, often exceeding 92%. Their surface quality is exceptionally smooth and uniform, making them ideal for applications requiring precision and aesthetic appeal. In contrast, acrylic extruded sheets may have slight variations in thickness and surface finish, leading to reduced optical clarity and less consistent surface quality.

Thickness Tolerance and Size Availability

Acrylic cast sheets offer superior thickness tolerance, typically within +-0.2 mm, and feature a wide range of size availability with custom dimensions up to 1200 mm x 2400 mm. Extruded acrylic sheets have looser thickness tolerance, usually around +-0.3 mm, but are available in continuous lengths and standard sizes for easier fabrication. The choice between cast and extruded acrylic depends on the precision required and the specific dimensional needs of the application.

Strength and Durability Differences

Acrylic cast sheets exhibit superior strength and durability due to their manufacturing process, which results in higher molecular weight and fewer internal stresses compared to extruded sheets. Cast acrylic offers enhanced resistance to cracking, impact, and weathering, making it ideal for demanding applications requiring long-term performance. Extruded sheets, while more affordable and easier to fabricate, generally have lower impact resistance and may be prone to stress-induced brittleness over time.

Machining, Fabrication, and Workability

Acrylic cast sheets offer superior machining capabilities due to their higher molecular weight and uniform structure, resulting in cleaner cuts and smoother edges compared to extruded sheets. Extruded acrylic sheets excel in fabrication processes like thermoforming and bending, thanks to their increased flexibility and decreased brittleness. Workability of cast acrylic is ideal for applications requiring detailed machining and polishing, while extruded acrylic suits projects demanding fast fabrication and reduced risk of cracking.

Common Applications: Cast vs Extruded Acrylic

Cast acrylic sheets are widely used in applications requiring superior optical clarity and durability, such as display cases, aquariums, and high-end signage. Extruded acrylic sheets are preferred for projects involving cost-effective fabrication and consistent thickness, often found in point-of-sale displays, skylights, and light fixtures. Both types serve distinct purposes in architectural, automotive, and retail industries due to their unique manufacturing processes and material properties.

Cost Comparison: Cast Sheet vs Extruded Sheet

Acrylic cast sheets generally incur higher production costs due to their long curing process and superior optical clarity, making them more expensive than extruded sheets. Extruded acrylic sheets are manufactured through a continuous extrusion process, resulting in lower material costs and faster production times, which reduces their overall price. For applications prioritizing budget over premium quality, extruded acrylic sheets offer a more cost-effective solution.

Choosing the Right Acrylic Sheet for Your Project

Acrylic cast sheets offer superior optical clarity, enhanced chemical resistance, and better dimensional stability, making them ideal for high-precision applications like displays and signage. Acrylic extruded sheets are more cost-effective and provide consistent thickness, suitable for general-purpose projects with lower performance requirements. Evaluating factors such as budget, durability, clarity, and post-processing needs ensures selecting the right acrylic sheet type for your specific project demands.

Acrylic Cast Sheet vs Acrylic Extruded Sheet Infographic

materialdif.com

materialdif.com