Acrylic adhesive provides strong bonding with excellent flexibility and UV resistance, making it ideal for outdoor acrylic pet applications requiring durability and weather resistance. Epoxy adhesive offers superior strength and chemical resistance but cures harder and is less flexible, which may cause cracking under stress or impact. Choosing between acrylic and epoxy adhesives depends on the specific mechanical and environmental demands of the acrylic pet project.

Table of Comparison

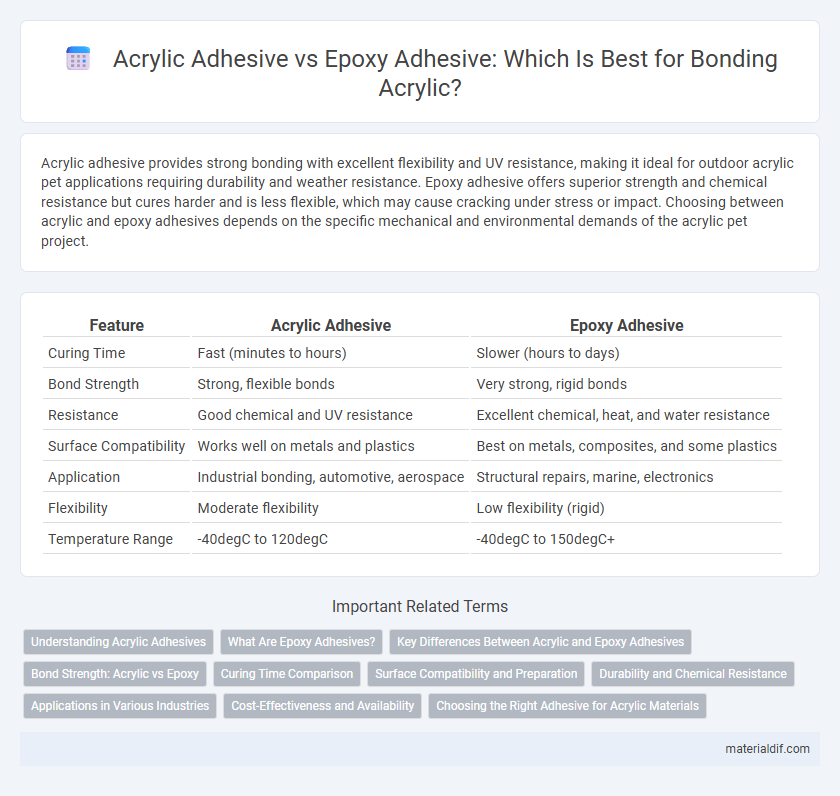

| Feature | Acrylic Adhesive | Epoxy Adhesive |

|---|---|---|

| Curing Time | Fast (minutes to hours) | Slower (hours to days) |

| Bond Strength | Strong, flexible bonds | Very strong, rigid bonds |

| Resistance | Good chemical and UV resistance | Excellent chemical, heat, and water resistance |

| Surface Compatibility | Works well on metals and plastics | Best on metals, composites, and some plastics |

| Application | Industrial bonding, automotive, aerospace | Structural repairs, marine, electronics |

| Flexibility | Moderate flexibility | Low flexibility (rigid) |

| Temperature Range | -40degC to 120degC | -40degC to 150degC+ |

Understanding Acrylic Adhesives

Acrylic adhesives offer fast curing times and excellent resistance to environmental factors, making them ideal for bonding metals, plastics, and glass. Their unique chemical composition provides strong bonding strength while maintaining flexibility and impact resistance, unlike epoxy adhesives that cure slower and tend to be more rigid. Understanding acrylic adhesives involves recognizing their superior performance in applications requiring quick assembly and durability under stress or varying temperatures.

What Are Epoxy Adhesives?

Epoxy adhesives are thermosetting polymers known for their exceptional bonding strength, chemical resistance, and durability, making them ideal for heavy-duty applications. They consist of two components--a resin and a hardener--that, when mixed, cure to form a rigid, high-performance adhesive suitable for bonding metals, plastics, and composites. Unlike acrylic adhesives, epoxy adhesives provide superior gap-filling capabilities and resistance to environmental stress, making them preferred in aerospace, automotive, and structural industries.

Key Differences Between Acrylic and Epoxy Adhesives

Acrylic adhesives offer faster curing times and better flexibility compared to epoxy adhesives, which are known for their superior strength and excellent resistance to chemicals and high temperatures. Acrylics bond well to a variety of substrates including plastics and metals, while epoxies provide stronger adhesion on porous surfaces such as wood and concrete. The choice between acrylic and epoxy adhesives depends on application requirements like curing speed, environmental resistance, and substrate compatibility.

Bond Strength: Acrylic vs Epoxy

Acrylic adhesives offer superior bond strength on a wide variety of substrates, including metals, plastics, and composites, often providing faster curing times compared to epoxy adhesives. Epoxy adhesives typically deliver exceptional bond strength on porous materials like wood and concrete, with high resistance to chemicals and heat. When evaluating bond strength specifically, acrylic adhesives excel in impact resistance and flexibility, while epoxies provide stiffer, more rigid bonds suited for structural applications.

Curing Time Comparison

Acrylic adhesives typically cure faster than epoxy adhesives, with curing times ranging from 5 to 30 minutes, depending on the formulation and environmental conditions. Epoxy adhesives generally require longer curing periods, often between 1 to 24 hours, to achieve full strength due to their two-part chemical reaction. This difference in curing time makes acrylic adhesives preferable for applications demanding quick bonding and rapid handling.

Surface Compatibility and Preparation

Acrylic adhesive offers superior compatibility with a wide range of surfaces, including metals, plastics, and composites, requiring minimal surface preparation such as cleaning and light abrasion. Epoxy adhesive demands more intensive surface preparation, often involving thorough degreasing, sanding, and sometimes primer application to ensure optimal bonding on materials like metal, wood, and concrete. The choice between acrylic and epoxy adhesives hinges on the substrate type and the readiness to invest in surface treatment to achieve durable, high-strength adhesion.

Durability and Chemical Resistance

Acrylic adhesive offers high durability with excellent resistance to impact, UV exposure, and temperature fluctuations, making it ideal for outdoor and dynamic applications. Epoxy adhesive provides superior chemical resistance, particularly against solvents, acids, and alkalis, ensuring long-lasting bonds in harsh chemical environments. While epoxy excels in chemical resistance, acrylic adhesives maintain better flexibility and weather resistance, influencing the choice between the two based on specific durability and chemical exposure requirements.

Applications in Various Industries

Acrylic adhesive offers superior flexibility and fast curing times, making it ideal for automotive assembly, electronics bonding, and medical device manufacturing where quick handling and resistance to environmental stress are critical. Epoxy adhesive provides exceptional mechanical strength and chemical resistance, preferred in aerospace, construction, and marine industries for structural bonding and high-load applications. Both adhesives excel in industrial usage, with acrylics favored for speed and durability, and epoxies chosen for heavy-duty and high-performance environments.

Cost-Effectiveness and Availability

Acrylic adhesives provide a cost-effective solution with fast curing times and strong bond strength, making them widely available in various formulations for industrial and everyday use. Epoxy adhesives, while generally more expensive, offer superior durability and chemical resistance, but their limited availability and longer curing periods can impact overall cost-efficiency. Choosing between acrylic and epoxy adhesives depends on specific project requirements, balancing upfront material costs with performance and accessibility.

Choosing the Right Adhesive for Acrylic Materials

Acrylic adhesives provide excellent clarity and UV resistance, making them ideal for bonding transparent or decorative acrylic materials without yellowing over time. Epoxy adhesives offer superior strength and chemical resistance, suitable for structural or load-bearing acrylic applications where durability is critical. Selecting the appropriate adhesive depends on balancing optical clarity with mechanical performance requirements tailored to the specific acrylic project.

Acrylic Adhesive vs Epoxy Adhesive Infographic

materialdif.com

materialdif.com