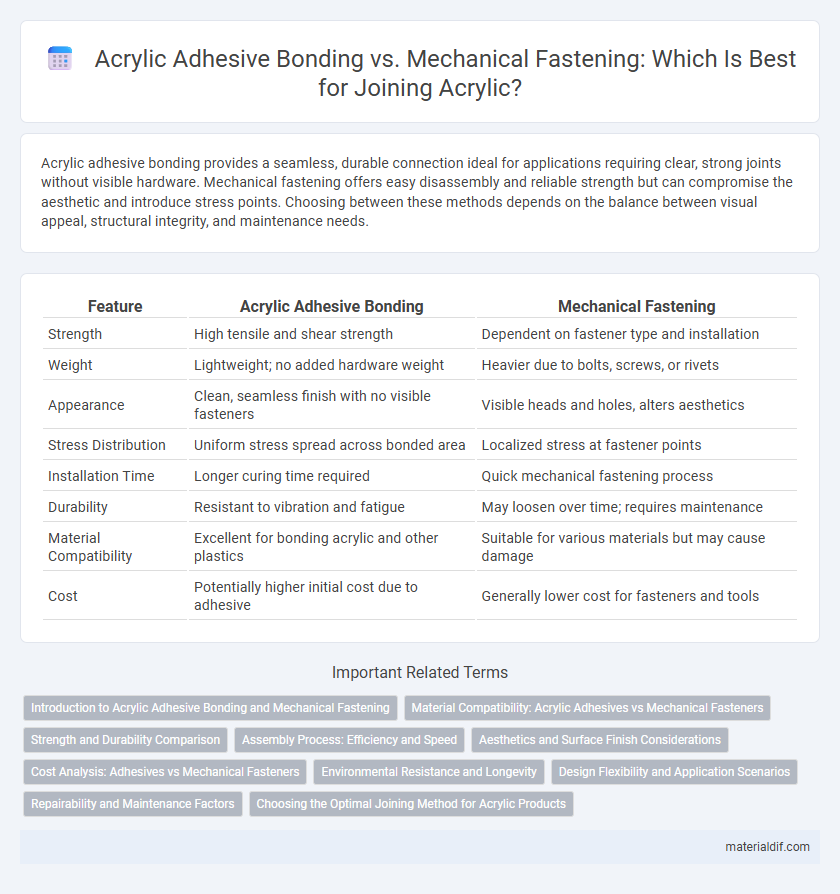

Acrylic adhesive bonding provides a seamless, durable connection ideal for applications requiring clear, strong joints without visible hardware. Mechanical fastening offers easy disassembly and reliable strength but can compromise the aesthetic and introduce stress points. Choosing between these methods depends on the balance between visual appeal, structural integrity, and maintenance needs.

Table of Comparison

| Feature | Acrylic Adhesive Bonding | Mechanical Fastening |

|---|---|---|

| Strength | High tensile and shear strength | Dependent on fastener type and installation |

| Weight | Lightweight; no added hardware weight | Heavier due to bolts, screws, or rivets |

| Appearance | Clean, seamless finish with no visible fasteners | Visible heads and holes, alters aesthetics |

| Stress Distribution | Uniform stress spread across bonded area | Localized stress at fastener points |

| Installation Time | Longer curing time required | Quick mechanical fastening process |

| Durability | Resistant to vibration and fatigue | May loosen over time; requires maintenance |

| Material Compatibility | Excellent for bonding acrylic and other plastics | Suitable for various materials but may cause damage |

| Cost | Potentially higher initial cost due to adhesive | Generally lower cost for fasteners and tools |

Introduction to Acrylic Adhesive Bonding and Mechanical Fastening

Acrylic adhesive bonding offers a strong, durable, and aesthetically clean solution for joining materials without the need for drilling or additional hardware. Mechanical fastening involves using screws, bolts, or rivets to physically hold parts together, providing immediate and adjustable strength but often compromising surface integrity. Choosing between acrylic adhesive bonding and mechanical fastening depends on factors like load requirements, environmental resistance, and design considerations.

Material Compatibility: Acrylic Adhesives vs Mechanical Fasteners

Acrylic adhesives offer superior compatibility with a wide range of substrates including plastics, metals, and composites, creating strong, flexible bonds that distribute stress evenly across surfaces. Mechanical fasteners such as screws and bolts may cause stress concentrations and potential damage to acrylic materials, leading to cracks or fractures over time. The chemical bonding properties of acrylic adhesives enhance durability and aesthetic integrity, making them preferable for applications requiring seamless, reliable joins without compromising material integrity.

Strength and Durability Comparison

Acrylic adhesive bonding provides superior strength by creating a uniform stress distribution across bonded surfaces, minimizing the risk of stress concentrations common in mechanical fastening. The durability of acrylic bonds is enhanced by excellent resistance to environmental factors such as moisture, chemicals, and temperature fluctuations, outperforming traditional mechanical fasteners prone to corrosion and loosening. Mechanically fastened joints can suffer from fatigue and loosening over time, while acrylic adhesive bonds maintain long-term integrity with consistent load-bearing capacity.

Assembly Process: Efficiency and Speed

Acrylic adhesive bonding streamlines the assembly process by providing faster application and curing times compared to mechanical fastening, reducing labor and equipment requirements. The uniform distribution of stress through the adhesive enhances joint durability without the need for drilling or additional hardware. This efficiency minimizes assembly steps and speeds up production cycles, making acrylic bonding ideal for high-volume manufacturing.

Aesthetics and Surface Finish Considerations

Acrylic adhesive bonding provides a seamless, clean finish without visible fasteners, enhancing the aesthetic appeal and preserving the smooth surface integrity of acrylic components. Mechanical fastening often creates stress points and visible hardware, which can disrupt the sleek appearance and may cause surface distortions or damage over time. The choice of bonding method directly impacts the visual quality and long-term durability of acrylic surfaces in design applications.

Cost Analysis: Adhesives vs Mechanical Fasteners

Acrylic adhesive bonding often reduces overall manufacturing costs by minimizing labor-intensive assembly processes and eliminating the need for drilling or additional hardware required in mechanical fastening. While mechanical fasteners may have a lower initial material cost, the expenses associated with equipment, installation time, and potential damage to components frequently lead to higher total costs. Long-term benefits of acrylic adhesives include enhanced joint durability and reduced maintenance, contributing to cost efficiency over the product lifecycle.

Environmental Resistance and Longevity

Acrylic adhesive bonding offers superior environmental resistance compared to mechanical fastening, providing excellent durability against moisture, UV radiation, and temperature fluctuations. The bond formed by acrylic adhesives maintains long-term integrity without corrosion or stress concentration, ensuring extended lifespan in harsh conditions. Mechanical fasteners often fail due to rust, loosening, or material fatigue, making acrylic adhesive bonding the preferred choice for applications demanding robust and lasting environmental performance.

Design Flexibility and Application Scenarios

Acrylic adhesive bonding offers superior design flexibility by enabling seamless joints without the need for additional hardware, allowing for complex shapes and lightweight constructions in automotive, aerospace, and electronics applications. Mechanical fastening, while providing strong and easily reversible connections, often limits design options due to the need for holes, rivets, or screws, which can add weight and stress concentration points. Acrylic adhesives excel in applications requiring smooth surfaces, aesthetic appeal, and resistance to vibration, whereas mechanical fasteners are preferred for components subject to high shear forces or frequent disassembly.

Repairability and Maintenance Factors

Acrylic adhesive bonding provides superior repairability and maintenance advantages over mechanical fastening by creating seamless joints that resist environmental degradation and distribute stress evenly, reducing the need for frequent repairs. Mechanical fasteners often introduce stress concentration points and may loosen over time, requiring regular inspection and potential replacement, which can complicate maintenance processes. The use of acrylic adhesives enables quicker, cleaner repairs as damaged areas can be rebonded without additional hardware, enhancing overall durability and lifecycle performance.

Choosing the Optimal Joining Method for Acrylic Products

Acrylic adhesive bonding offers superior clarity and stress distribution, making it ideal for seamless, visually appealing joints in acrylic products. Mechanical fastening provides greater strength and ease of disassembly but can create stress points and compromise the acrylic's aesthetic. Evaluating factors such as load requirements, environmental conditions, and design complexity ensures choosing the optimal joining method for durable and visually optimal acrylic assemblies.

Acrylic Adhesive Bonding vs Mechanical Fastening Infographic

materialdif.com

materialdif.com