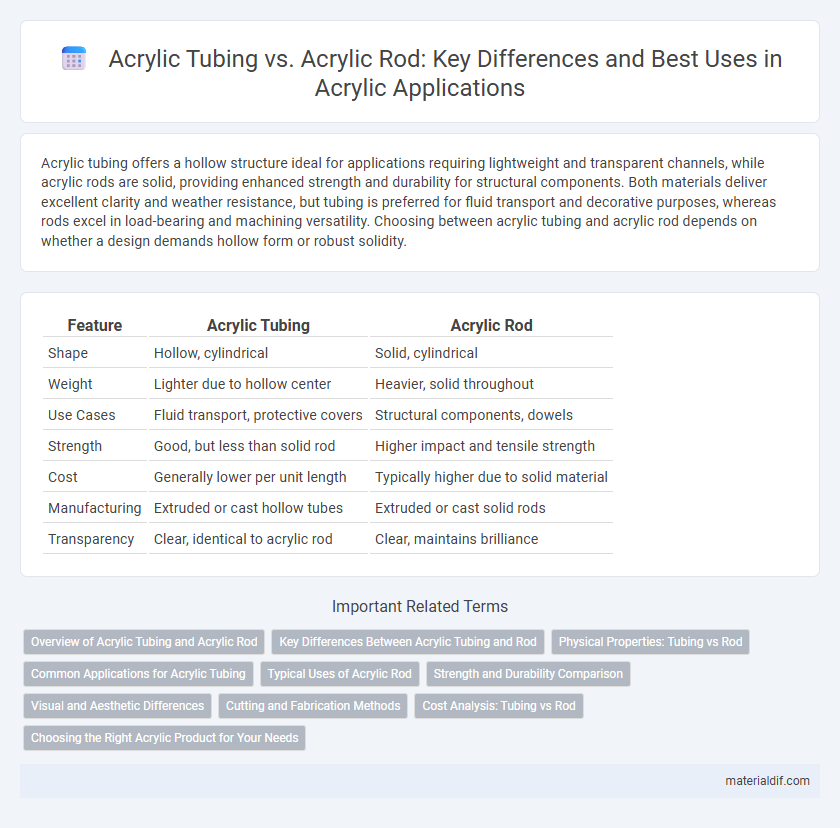

Acrylic tubing offers a hollow structure ideal for applications requiring lightweight and transparent channels, while acrylic rods are solid, providing enhanced strength and durability for structural components. Both materials deliver excellent clarity and weather resistance, but tubing is preferred for fluid transport and decorative purposes, whereas rods excel in load-bearing and machining versatility. Choosing between acrylic tubing and acrylic rod depends on whether a design demands hollow form or robust solidity.

Table of Comparison

| Feature | Acrylic Tubing | Acrylic Rod |

|---|---|---|

| Shape | Hollow, cylindrical | Solid, cylindrical |

| Weight | Lighter due to hollow center | Heavier, solid throughout |

| Use Cases | Fluid transport, protective covers | Structural components, dowels |

| Strength | Good, but less than solid rod | Higher impact and tensile strength |

| Cost | Generally lower per unit length | Typically higher due to solid material |

| Manufacturing | Extruded or cast hollow tubes | Extruded or cast solid rods |

| Transparency | Clear, identical to acrylic rod | Clear, maintains brilliance |

Overview of Acrylic Tubing and Acrylic Rod

Acrylic tubing features a hollow center, making it ideal for applications requiring fluid transport, structural frames, or display cases, while acrylic rods are solid, providing superior strength and durability for artistic projects, machining, and load-bearing components. Both materials offer excellent clarity, UV resistance, and weatherability, but choosing between tubing and rods depends on specific design needs such as weight, transparency, and mechanical strength. Common uses of acrylic tubing include aquariums and medical devices, whereas acrylic rods are preferred for custom furniture, lighting fixtures, and optical components.

Key Differences Between Acrylic Tubing and Rod

Acrylic tubing differs from acrylic rod primarily in shape and application: tubing is hollow and designed for fluid or air transport, while rod is solid and used for structural or decorative purposes. The hollow structure of acrylic tubing makes it lightweight and suitable for projects requiring transparency and flow, whereas acrylic rod provides greater strength and rigidity for machined or load-bearing applications. Both materials offer excellent clarity and weather resistance but are chosen based on whether a hollow or solid form is essential for the specific use case.

Physical Properties: Tubing vs Rod

Acrylic tubing is hollow with a consistent wall thickness, offering lightweight strength and flexibility suitable for fluid transport and structural framing. Acrylic rod is solid, denser, and more impact-resistant, ideal for applications requiring rigidity and durability such as display stands or machine components. Both materials feature excellent optical clarity and UV resistance, but tubing emphasizes weight reduction while rods provide enhanced mechanical stability.

Common Applications for Acrylic Tubing

Acrylic tubing is widely used in medical and laboratory settings for fluid transfer and chemical processing due to its clarity, rigidity, and resistance to UV light. Its hollow cylindrical shape makes it ideal for applications such as displays, aquariums, and protective barriers where visibility and structural integrity are crucial. Acrylic rods, while useful for solid structural uses, do not provide the same versatility for fluid flow and containment found in acrylic tubing.

Typical Uses of Acrylic Rod

Acrylic rod is commonly used in applications requiring structural strength and clarity, such as display cases, signage, and architectural accents. Its solid form makes it ideal for machining into custom components, optical lenses, and decorative elements. Compared to acrylic tubing, acrylic rod offers enhanced durability and versatility for load-bearing and precision-crafted projects.

Strength and Durability Comparison

Acrylic tubing offers enhanced impact resistance and flexibility compared to acrylic rod, making it less prone to cracking under stress. Acrylic rods exhibit higher tensile strength and rigidity, providing superior load-bearing capacity for structural applications. Both materials maintain excellent weather resistance and UV stability, but acrylic rods generally deliver greater long-term durability in demanding environments.

Visual and Aesthetic Differences

Acrylic tubing features a hollow, cylindrical shape that allows for light transmission and can create unique lighting effects, making it ideal for decorative applications and displays. In contrast, acrylic rods are solid and offer a smooth, polished surface that emphasizes clarity and depth, enhancing sculptures and optical designs. The tubular form highlights transparency and illumination, while the rod's density provides a more substantial, glass-like appearance.

Cutting and Fabrication Methods

Acrylic tubing and acrylic rod differ significantly in cutting and fabrication methods; tubing requires precision tools like pipe cutters or band saws to ensure clean, straight cuts without cracking, while rods are often cut with saws or CNC machines for detailed shaping. Heating techniques such as flame polishing and bending are commonly used on tubing to achieve smooth edges and curved forms, whereas rods are frequently machined or turned on lathes to create complex profiles. Both materials benefit from careful handling during fabrication to maintain optical clarity and structural integrity.

Cost Analysis: Tubing vs Rod

Acrylic tubing generally costs less than acrylic rods due to lower material usage and simpler manufacturing processes. Rods require more raw material and often undergo additional machining, increasing their price per unit length or weight. When comparing costs for applications requiring hollow or lightweight structures, tubing offers a more economical option, while rods provide better strength at a higher cost.

Choosing the Right Acrylic Product for Your Needs

Acrylic tubing provides a hollow structure ideal for applications requiring fluid or gas flow, while acrylic rods offer solid material strength suited for structural uses or detailed machining. Selecting between acrylic tubing and acrylic rods depends on factors like required transparency, weight, durability, and specific project dimensions. Understanding these material properties ensures optimal performance and cost-effectiveness in construction, manufacturing, or DIY projects.

Acrylic Tubing vs Acrylic Rod Infographic

materialdif.com

materialdif.com