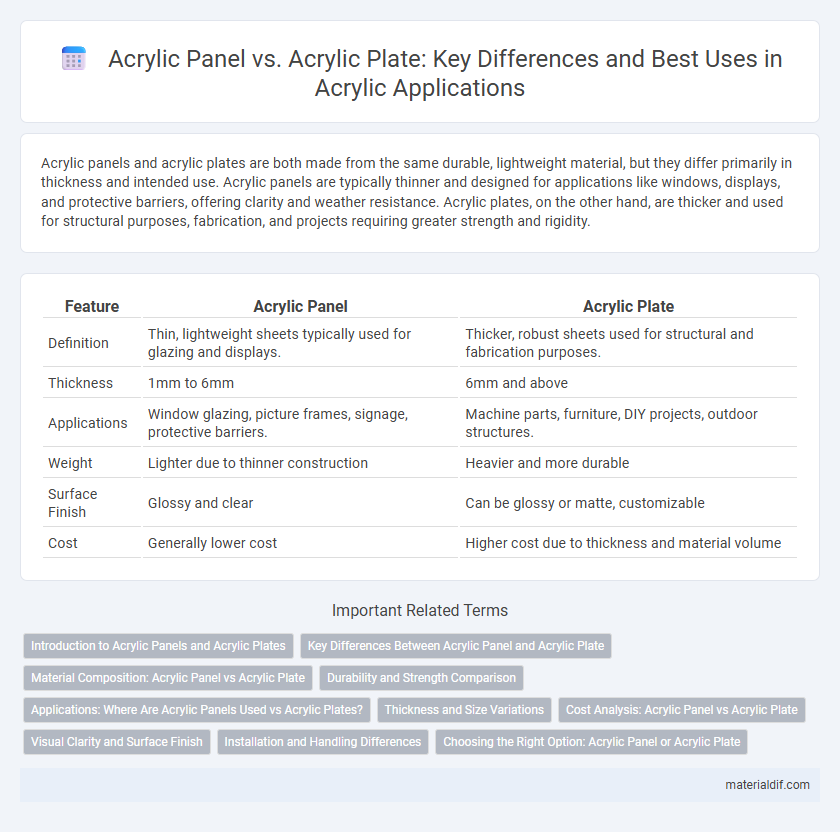

Acrylic panels and acrylic plates are both made from the same durable, lightweight material, but they differ primarily in thickness and intended use. Acrylic panels are typically thinner and designed for applications like windows, displays, and protective barriers, offering clarity and weather resistance. Acrylic plates, on the other hand, are thicker and used for structural purposes, fabrication, and projects requiring greater strength and rigidity.

Table of Comparison

| Feature | Acrylic Panel | Acrylic Plate |

|---|---|---|

| Definition | Thin, lightweight sheets typically used for glazing and displays. | Thicker, robust sheets used for structural and fabrication purposes. |

| Thickness | 1mm to 6mm | 6mm and above |

| Applications | Window glazing, picture frames, signage, protective barriers. | Machine parts, furniture, DIY projects, outdoor structures. |

| Weight | Lighter due to thinner construction | Heavier and more durable |

| Surface Finish | Glossy and clear | Can be glossy or matte, customizable |

| Cost | Generally lower cost | Higher cost due to thickness and material volume |

Introduction to Acrylic Panels and Acrylic Plates

Acrylic panels and acrylic plates are both versatile sheets made from polymethyl methacrylate (PMMA), commonly used in construction, signage, and design applications due to their clarity and durability. Acrylic panels typically refer to larger, thinner sheets designed for glazing, partitions, and protective covers, while acrylic plates are thicker and more rigid, often utilized in fabrication and machining projects. Both materials offer excellent optical transparency, weather resistance, and impact strength, making them suitable for a wide range of industrial and creative purposes.

Key Differences Between Acrylic Panel and Acrylic Plate

Acrylic panels are typically thinner, designed for applications such as glazing, signage, and protective screens, while acrylic plates are thicker and used in structural or load-bearing scenarios. Panels often come in large, flat sheets with a smooth surface finish, whereas plates offer enhanced durability and resistance to impact due to their increased thickness. The key differences lie in their intended use, thickness, and mechanical strength, making panels ideal for visibility-focused uses and plates suitable for robust construction needs.

Material Composition: Acrylic Panel vs Acrylic Plate

Acrylic panels and acrylic plates are both made from polymethyl methacrylate (PMMA), a transparent thermoplastic known for its clarity and strength. Acrylic panels are typically thinner and used for applications requiring lightweight, flexible materials, while acrylic plates are thicker, providing greater durability and impact resistance. The slight differences in polymer density and manufacturing processes influence their mechanical properties and optimal usage scenarios.

Durability and Strength Comparison

Acrylic panels offer superior impact resistance and flexibility, making them less prone to cracking under pressure compared to acrylic plates, which are thicker and provide enhanced stiffness and load-bearing capacity. The durability of acrylic panels is ideal for applications requiring transparent barriers or signage, while acrylic plates are better suited for structural uses demanding higher mechanical strength and rigidity. Both materials resist UV deterioration and weathering, but the choice depends on specific strength requirements and environmental exposure.

Applications: Where Are Acrylic Panels Used vs Acrylic Plates?

Acrylic panels are widely used in applications requiring large, flat surfaces such as glazing, signage, and protective barriers due to their excellent clarity and impact resistance. Acrylic plates are preferred in fabrication and machining processes, making them ideal for custom parts, displays, and structural components where precise dimensions are critical. Both materials are valued for their versatility, with panels dominating architectural and commercial uses while plates excel in industrial and design applications.

Thickness and Size Variations

Acrylic panels typically come in larger dimensions with thickness ranging from 2mm to 25mm, making them ideal for extensive applications like signage and glazing. Acrylic plates offer more precise size and thickness options, often available in smaller sheets from 1mm up to 30mm, suitable for detailed fabrication and custom projects. Both types allow for customization, but panels are preferred when wide coverage is required, while plates cater to versatility in thickness and cutting.

Cost Analysis: Acrylic Panel vs Acrylic Plate

Acrylic panels generally offer a more cost-effective solution for large-scale applications due to their standardized thickness and dimensions, resulting in lower material waste and easier fabrication. Acrylic plates, being custom-cut and often thicker, tend to incur higher manufacturing and processing costs, especially for complex shapes or smaller quantities. Evaluating the total project budget, acrylic panels provide better value in bulk purchases, while acrylic plates suit specialized needs despite their premium price.

Visual Clarity and Surface Finish

Acrylic panels offer superior visual clarity due to their polished surface finish, which enhances light transmission and reduces distortion compared to acrylic plates. Acrylic plates typically have a matte or rougher finish on one or both sides, impacting overall transparency and making them less ideal for optical applications. The smooth, glossy surface of acrylic panels ensures high clarity, making them preferable for display cases, signage, and glazing where visual appeal is critical.

Installation and Handling Differences

Acrylic panels are typically thinner and lighter, making them easier to cut and install on surfaces like walls or displays using adhesives or screws. Acrylic plates, being thicker and more rigid, require special tools for cutting and more careful handling to prevent cracking or chipping during installation. The installation of acrylic plates often involves structural support due to their weight, while acrylic panels are more flexible and better suited for simple DIY applications.

Choosing the Right Option: Acrylic Panel or Acrylic Plate

Acrylic panels are typically thinner and used for applications like glazing, signage, and display cases, offering clarity and lightweight properties. Acrylic plates are thicker, providing enhanced durability and structural strength suited for fabrication, machining, or load-bearing uses. Selecting the right option depends on the specific application requirements, balancing factors like thickness, strength, and optical quality for optimal performance.

Acrylic Panel vs Acrylic Plate Infographic

materialdif.com

materialdif.com