Laser cut acrylic offers precise, clean edges and intricate detail capabilities, making it ideal for delicate designs and smooth finishes. CNC routed acrylic is better suited for thicker materials, providing robust cutting power and the ability to handle larger, more complex shapes with consistent accuracy. Choosing between laser cutting and CNC routing depends on the project specifications, material thickness, and desired edge quality.

Table of Comparison

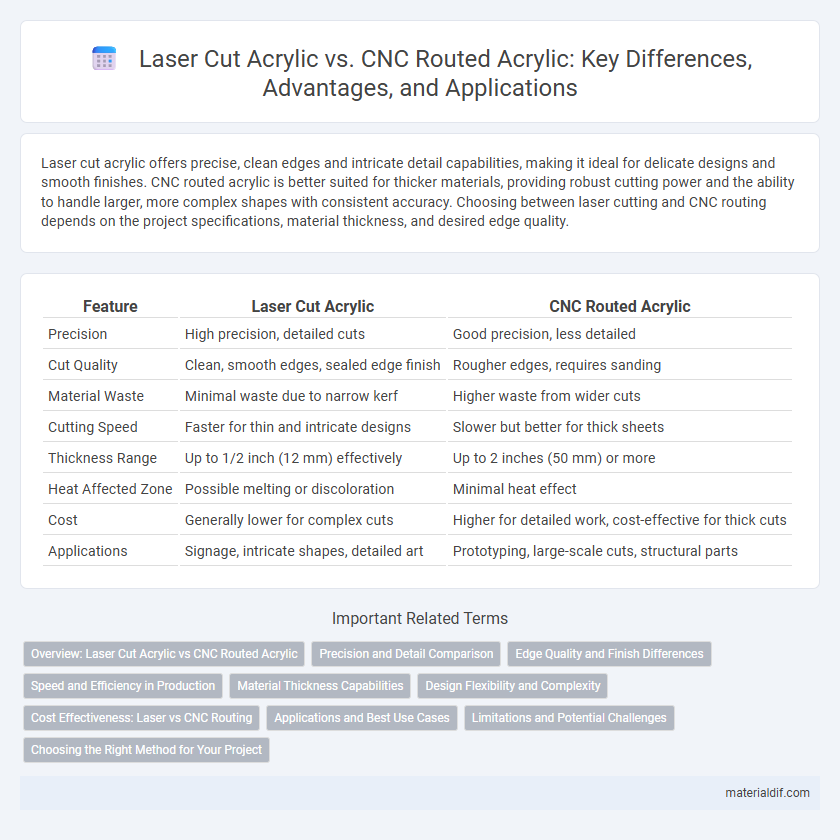

| Feature | Laser Cut Acrylic | CNC Routed Acrylic |

|---|---|---|

| Precision | High precision, detailed cuts | Good precision, less detailed |

| Cut Quality | Clean, smooth edges, sealed edge finish | Rougher edges, requires sanding |

| Material Waste | Minimal waste due to narrow kerf | Higher waste from wider cuts |

| Cutting Speed | Faster for thin and intricate designs | Slower but better for thick sheets |

| Thickness Range | Up to 1/2 inch (12 mm) effectively | Up to 2 inches (50 mm) or more |

| Heat Affected Zone | Possible melting or discoloration | Minimal heat effect |

| Cost | Generally lower for complex cuts | Higher for detailed work, cost-effective for thick cuts |

| Applications | Signage, intricate shapes, detailed art | Prototyping, large-scale cuts, structural parts |

Overview: Laser Cut Acrylic vs CNC Routed Acrylic

Laser cut acrylic produces precise, clean edges with high detail, making it ideal for intricate designs and smooth finishes. CNC routed acrylic removes material mechanically, allowing for thicker cuts and deeper engraving but may leave slightly rougher edges. Choosing between laser cutting and CNC routing depends on project complexity, thickness, and desired edge quality.

Precision and Detail Comparison

Laser cut acrylic offers superior precision with the ability to create intricate and delicate designs through a focused beam that ensures clean, smooth edges. CNC routed acrylic provides robust detailed cuts but may lack the fine accuracy of laser cutting due to the mechanical contact of the router bit. The choice depends on required detail intricacy; laser cutting excels in complex, high-precision applications while CNC routing suits thicker materials and larger, less detailed projects.

Edge Quality and Finish Differences

Laser cut acrylic produces smooth, polished edges with a glossy finish due to precise thermal melting, eliminating the need for secondary finishing. CNC routed acrylic often results in edges that are slightly rougher and may require sanding or polishing to achieve a similar smoothness. The laser cutting process excels in producing sharp, clean edges ideal for intricate designs, while CNC routing allows for thicker material handling but with less refined edge quality.

Speed and Efficiency in Production

Laser cut acrylic offers superior speed and precision, making it ideal for intricate designs and rapid prototyping with minimal material waste. CNC routed acrylic excels in handling thicker sheets and larger production runs, providing consistent depth and clean edges but generally requires longer setup and cutting times. Choosing between laser cutting and CNC routing depends on balancing the need for detailed accuracy against volume efficiency and material thickness.

Material Thickness Capabilities

Laser cut acrylic excels in precision for thinner sheets, typically handling thicknesses up to 1/2 inch with clean, smooth edges and minimal heat-affected zones. CNC routed acrylic accommodates thicker materials, often up to 2 inches or more, allowing for deeper cuts and complex three-dimensional shapes. Choosing between laser cutting and CNC routing depends on the thickness and complexity required for the acrylic project.

Design Flexibility and Complexity

Laser cut acrylic offers superior design flexibility and precision, enabling intricate patterns and fine details with clean, smooth edges. CNC routed acrylic excels in creating thicker, more robust shapes and can handle complex 3D contours that require depth variation. Both methods optimize acrylic fabrication, but laser cutting is preferred for delicate, precise designs while CNC routing supports versatile, heavy-duty projects.

Cost Effectiveness: Laser vs CNC Routing

Laser cut acrylic typically offers higher cost-effectiveness for intricate designs due to its precision and minimal material waste, reducing overall production expenses. CNC routed acrylic may involve greater costs because of longer setup times and higher tool maintenance, making it less economical for detailed or small-scale projects. For larger, less complex shapes, CNC routing can be more cost-efficient by enabling faster material removal at lower operational costs.

Applications and Best Use Cases

Laser cut acrylic offers high precision and clean edges, making it ideal for intricate designs, signage, and detailed decorative pieces. CNC routed acrylic is better suited for thicker sheets and producing larger components such as furniture parts and industrial enclosures due to its ability to handle aggressive cutting forces. Choosing between laser cutting and CNC routing depends on the complexity of the design, material thickness, and the desired finish quality.

Limitations and Potential Challenges

Laser cut acrylic offers precise, intricate designs with clean edges but struggles with thickness limitations, typically up to 1/2 inch, and may cause melting or discoloration on thicker materials. CNC routed acrylic handles thicker sheets beyond 1/2 inch and can produce smooth edges on large parts but often results in tool marks and less intricate detail compared to laser cutting. Both methods require careful consideration of acrylic type and thickness to avoid stress fractures and ensure optimal finishing quality.

Choosing the Right Method for Your Project

Laser cut acrylic offers precise, clean edges and intricate detailing, making it ideal for projects requiring fine accuracy and smooth finishes. CNC routed acrylic suits thicker sheets and designs involving deeper cuts or complex 3D shapes, providing robust sculpting capabilities and versatility. Selecting the right method depends on factors like material thickness, design complexity, edge quality preferences, and production volume requirements.

Laser Cut Acrylic vs CNC Routed Acrylic Infographic

materialdif.com

materialdif.com