Acrylic UV printing offers vibrant, long-lasting colors that resist fading and scratching, making it ideal for high-quality displays and signage. Vinyl printing provides a cost-effective solution with ease of application and removal, suitable for temporary or flexible designs. Choosing between the two depends on durability needs and budget constraints.

Table of Comparison

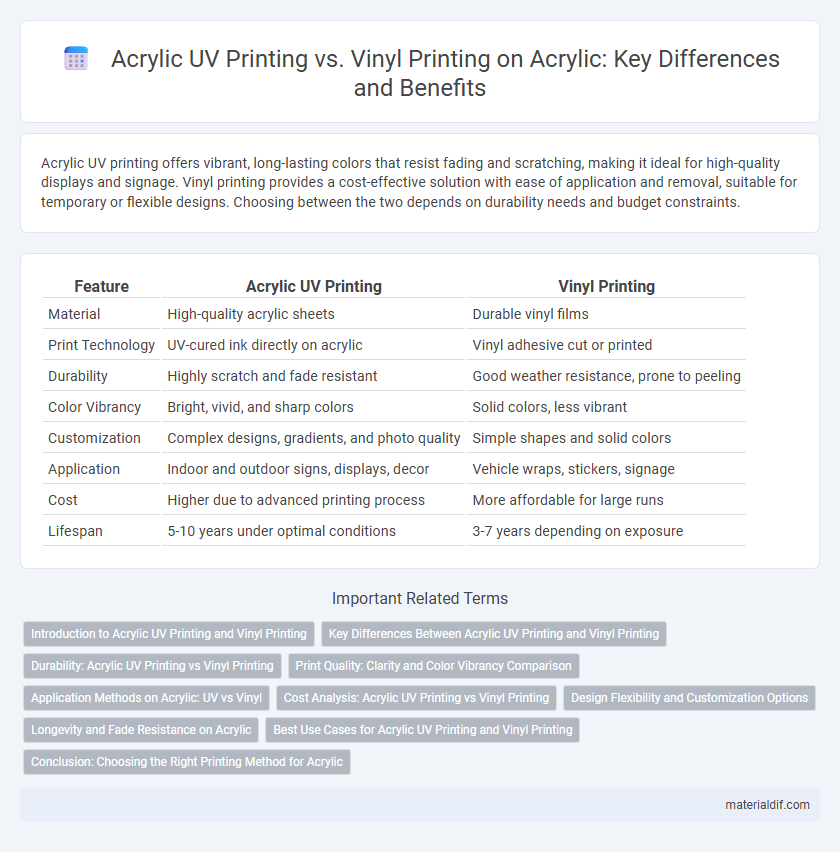

| Feature | Acrylic UV Printing | Vinyl Printing |

|---|---|---|

| Material | High-quality acrylic sheets | Durable vinyl films |

| Print Technology | UV-cured ink directly on acrylic | Vinyl adhesive cut or printed |

| Durability | Highly scratch and fade resistant | Good weather resistance, prone to peeling |

| Color Vibrancy | Bright, vivid, and sharp colors | Solid colors, less vibrant |

| Customization | Complex designs, gradients, and photo quality | Simple shapes and solid colors |

| Application | Indoor and outdoor signs, displays, decor | Vehicle wraps, stickers, signage |

| Cost | Higher due to advanced printing process | More affordable for large runs |

| Lifespan | 5-10 years under optimal conditions | 3-7 years depending on exposure |

Introduction to Acrylic UV Printing and Vinyl Printing

Acrylic UV printing uses ultraviolet light to cure ink directly onto acrylic surfaces, resulting in vibrant, durable, and scratch-resistant graphics ideal for high-quality signage and displays. Vinyl printing involves transferring adhesive vinyl sheets onto surfaces, offering flexibility and ease of application, but with less resistance to environmental wear compared to UV-cured acrylic prints. Both methods serve different purposes, with UV printing excelling in long-lasting, detailed visuals on acrylic materials and vinyl printing providing cost-effective, customizable solutions for temporary or indoor applications.

Key Differences Between Acrylic UV Printing and Vinyl Printing

Acrylic UV printing offers high-resolution, vibrant, and durable prints directly on acrylic surfaces, making it ideal for long-lasting signage and display purposes. Vinyl printing involves cutting adhesive vinyl films that are applied to surfaces, providing flexibility and ease of customization but with less color depth and longevity compared to UV printing. Acrylic UV printing ensures superior resistance to fading, scratches, and weather elements, while vinyl is more cost-effective and suitable for temporary or indoor applications.

Durability: Acrylic UV Printing vs Vinyl Printing

Acrylic UV printing offers superior durability compared to vinyl printing due to its resistance to fading, cracking, and peeling under prolonged exposure to sunlight and harsh weather conditions. The UV-cured inks used in acrylic printing bond directly to the substrate, providing long-lasting, vibrant colors that maintain clarity over time. In contrast, vinyl prints may deteriorate faster as the adhesive and ink can degrade, reducing overall lifespan and visual appeal.

Print Quality: Clarity and Color Vibrancy Comparison

Acrylic UV printing delivers superior clarity and vibrant color reproduction due to its ability to print directly on the acrylic surface with high precision and UV-cured inks that resist fading and wear. Vinyl printing often results in less sharp images and color vibrancy as it relies on adhesive vinyl films, which can degrade over time and may not perfectly conform to complex acrylic surfaces. The durability and longevity of UV printing make it the preferred choice for vivid, high-quality acrylic displays and signage.

Application Methods on Acrylic: UV vs Vinyl

UV printing on acrylic involves directly applying ultraviolet-cured inks onto the surface, creating vibrant, durable, and scratch-resistant designs ideal for signage and decorative panels. Vinyl printing uses adhesive vinyl sheets that are cut and then applied to the acrylic surface, offering flexibility in design changes and cost-effectiveness for small-run or temporary applications. UV printing provides a seamless, high-resolution finish with enhanced weather resistance, while vinyl printing allows for easy removal and replacement without damaging the acrylic substrate.

Cost Analysis: Acrylic UV Printing vs Vinyl Printing

Acrylic UV printing typically incurs higher initial costs due to specialized UV printers and ink, but offers superior durability and vibrant color retention, making it cost-effective for long-term use. Vinyl printing generally has lower upfront expenses and faster production times but may require frequent replacements because of its susceptibility to fading and peeling. Considering the total lifecycle cost, acrylic UV printing often provides better value for projects demanding longevity and high-quality finishes.

Design Flexibility and Customization Options

Acrylic UV printing offers superior design flexibility with its ability to produce vibrant, high-resolution images directly on the material, accommodating intricate details and gradients. Vinyl printing provides customization options primarily through cut shapes and layered colors but lacks the fine detail reproduction of UV printing. The choice between the two hinges on the desired aesthetic complexity and the durability requirements of the printed design.

Longevity and Fade Resistance on Acrylic

Acrylic UV printing offers superior longevity and fade resistance compared to vinyl printing due to its ability to bond directly with the acrylic surface, providing enhanced durability against UV exposure and environmental factors. Vinyl printing, while versatile, tends to peel or crack over time when applied to acrylic, leading to premature fading and reduced lifespan. The inherent UV protective properties in UV-cured inks ensure vibrant, long-lasting colors on acrylic materials, making UV printing the preferred choice for outdoor and high-exposure applications.

Best Use Cases for Acrylic UV Printing and Vinyl Printing

Acrylic UV printing excels in producing vibrant, durable, and high-resolution graphics, making it ideal for retail displays, signage, and decorative panels requiring long-lasting color and clarity. Vinyl printing is best suited for flexible applications such as vehicle wraps, decals, and banners where adaptability and easy installation on curved or uneven surfaces are critical. Choosing between acrylic UV printing and vinyl printing depends on the material rigidity, environmental exposure, and the need for detailed imagery or flexibility.

Conclusion: Choosing the Right Printing Method for Acrylic

Acrylic UV printing offers superior durability, vibrant color accuracy, and resistance to fading, making it ideal for high-quality, long-lasting displays. Vinyl printing provides flexibility, ease of application, and cost-effectiveness, suitable for temporary or less demanding projects. Selecting between acrylic UV and vinyl printing depends on the project's longevity, budget, and desired visual impact.

Acrylic UV Printing vs Vinyl Printing Infographic

materialdif.com

materialdif.com