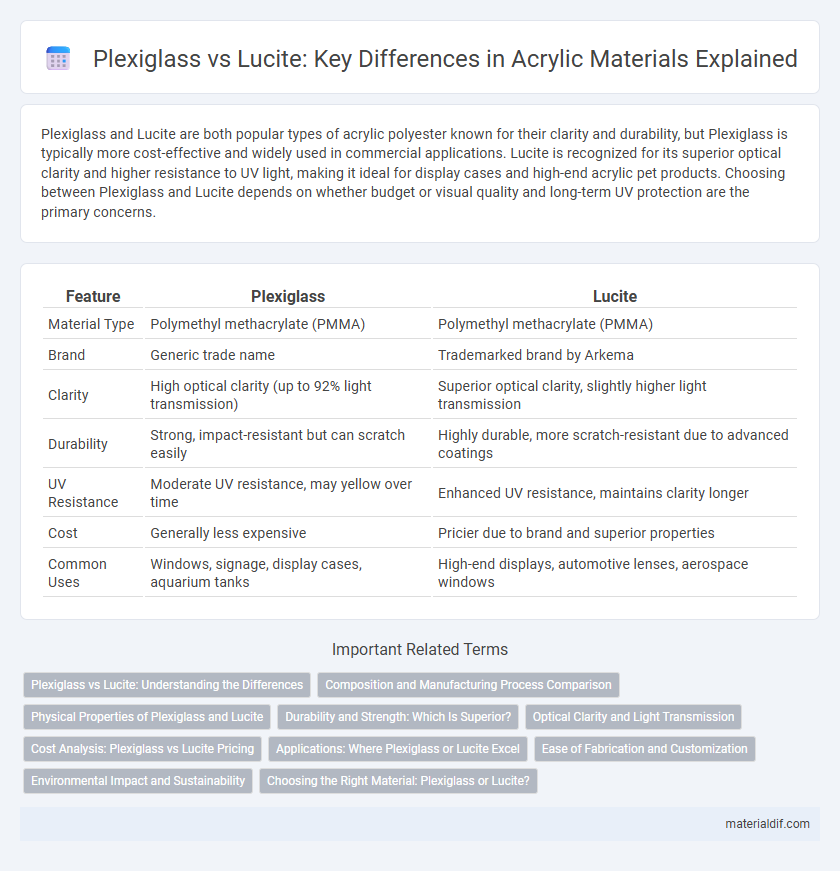

Plexiglass and Lucite are both popular types of acrylic polyester known for their clarity and durability, but Plexiglass is typically more cost-effective and widely used in commercial applications. Lucite is recognized for its superior optical clarity and higher resistance to UV light, making it ideal for display cases and high-end acrylic pet products. Choosing between Plexiglass and Lucite depends on whether budget or visual quality and long-term UV protection are the primary concerns.

Table of Comparison

| Feature | Plexiglass | Lucite |

|---|---|---|

| Material Type | Polymethyl methacrylate (PMMA) | Polymethyl methacrylate (PMMA) |

| Brand | Generic trade name | Trademarked brand by Arkema |

| Clarity | High optical clarity (up to 92% light transmission) | Superior optical clarity, slightly higher light transmission |

| Durability | Strong, impact-resistant but can scratch easily | Highly durable, more scratch-resistant due to advanced coatings |

| UV Resistance | Moderate UV resistance, may yellow over time | Enhanced UV resistance, maintains clarity longer |

| Cost | Generally less expensive | Pricier due to brand and superior properties |

| Common Uses | Windows, signage, display cases, aquarium tanks | High-end displays, automotive lenses, aerospace windows |

Plexiglass vs Lucite: Understanding the Differences

Plexiglass and Lucite are both brand names for acrylic sheets, but they differ in manufacturing processes and chemical composition, affecting clarity, durability, and resistance to UV light. Plexiglass tends to be more cost-effective and widely available, while Lucite is known for superior optical clarity and better weather resistance. Understanding these differences helps in selecting the appropriate material for applications requiring transparency, impact resistance, and longevity.

Composition and Manufacturing Process Comparison

Plexiglass and Lucite are both acrylic materials primarily composed of polymethyl methacrylate (PMMA), but they differ slightly in chemical formulation and molecular weight, which affects their clarity and strength. Plexiglass is manufactured through continuous polymerization resulting in sheets with consistent thickness, while Lucite uses batch cell casting, producing higher optical clarity and enhanced UV resistance. The manufacturing processes influence the durability and application; Plexiglass is favored for large-scale architectural uses, and Lucite is preferred in precision optics and high-end displays.

Physical Properties of Plexiglass and Lucite

Plexiglass and Lucite are both brand names for acrylic sheets with similar physical properties, including high transparency, excellent impact resistance, and lightweight durability. Plexiglass typically features a slightly higher scratch resistance and UV stability, making it ideal for outdoor applications, while Lucite is known for superior optical clarity and better resistance to yellowing over time. Both materials exhibit a tensile strength around 70 MPa and a density near 1.19 g/cm3, providing robust mechanical performance in various industrial and decorative uses.

Durability and Strength: Which Is Superior?

Plexiglass and Lucite are both types of acrylic known for their excellent durability and strength, with Lucite often touted as the superior option due to its higher resistance to impact and scratches. Plexiglass offers good toughness and clarity but may be more prone to surface damage compared to Lucite's enhanced scratch resistance. For applications requiring maximum durability and long-lasting strength, Lucite is generally recommended over standard Plexiglass.

Optical Clarity and Light Transmission

Plexiglass and Lucite both offer exceptional optical clarity, with Lucite often favored for its superior light transmission properties, allowing up to 92% of light to pass through compared to Plexiglass's approximately 88-90%. Lucite's chemical composition results in less distortion and higher transparency, making it ideal for applications requiring crisp visual clarity, such as display cases and lenses. Plexiglass remains a cost-effective alternative with good clarity but slightly lower light transmission, suitable for general glazing and protective barriers.

Cost Analysis: Plexiglass vs Lucite Pricing

Plexiglass typically costs between $15 to $30 per square foot, making it a more budget-friendly option compared to Lucite, which ranges from $25 to $60 per square foot due to its higher purity and clarity. Plexiglass's affordability stems from its widespread production and lower manufacturing costs, while Lucite's premium pricing reflects its superior impact resistance and optical quality. For projects prioritizing cost-efficiency without compromising basic acrylic properties, Plexiglass offers a practical advantage over Lucite.

Applications: Where Plexiglass or Lucite Excel

Plexiglass is widely used in automotive windows, protective barriers, and signage due to its superior impact resistance and weather durability. Lucite excels in optical clarity and UV resistance, making it ideal for high-end display cases, aquarium tanks, and skylights. Both materials perform well in marine environments, but Lucite's enhanced transparency makes it the preferred choice for underwater viewing panels.

Ease of Fabrication and Customization

Plexiglass offers superior ease of fabrication due to its higher impact resistance and ability to be cut, drilled, and thermoformed without cracking. Lucite provides excellent customization options with its vibrant clarity and ability to be cast into intricate shapes, making it ideal for detailed designs. Both materials support polishing and coloring, but Plexiglass is generally preferred for projects requiring quick modifications and robust handling.

Environmental Impact and Sustainability

Plexiglass and Lucite, both popular acrylic materials, differ in their environmental impact and sustainability profiles, with Plexiglass typically produced using energy-intensive processes that result in higher carbon emissions. Lucite offers enhanced recyclability and is often manufactured with a greater emphasis on reducing volatile organic compounds (VOCs), contributing to lower environmental pollution. Choosing Lucite can support sustainable building practices due to its longer lifespan and reduced ecological footprint compared to conventional Plexiglass.

Choosing the Right Material: Plexiglass or Lucite?

Plexiglass and Lucite are both popular acrylic materials known for their clarity and durability, but they differ in manufacturing processes and brand recognition. Plexiglass, typically produced by Extrusion, offers cost-effective versatility, while Lucite, created through Polymerization, provides superior optical clarity and UV resistance. Choosing between Plexiglass and Lucite depends on project requirements such as budget limits, exposure to sunlight, and desired surface quality.

Plexiglass vs Lucite Infographic

materialdif.com

materialdif.com