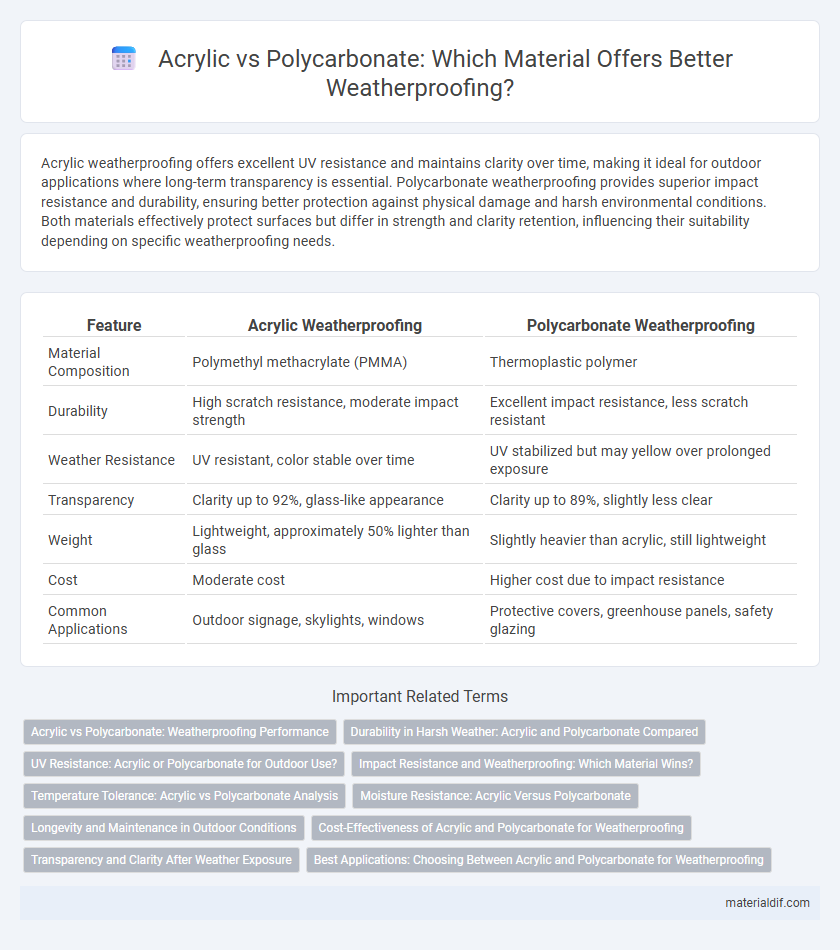

Acrylic weatherproofing offers excellent UV resistance and maintains clarity over time, making it ideal for outdoor applications where long-term transparency is essential. Polycarbonate weatherproofing provides superior impact resistance and durability, ensuring better protection against physical damage and harsh environmental conditions. Both materials effectively protect surfaces but differ in strength and clarity retention, influencing their suitability depending on specific weatherproofing needs.

Table of Comparison

| Feature | Acrylic Weatherproofing | Polycarbonate Weatherproofing |

|---|---|---|

| Material Composition | Polymethyl methacrylate (PMMA) | Thermoplastic polymer |

| Durability | High scratch resistance, moderate impact strength | Excellent impact resistance, less scratch resistant |

| Weather Resistance | UV resistant, color stable over time | UV stabilized but may yellow over prolonged exposure |

| Transparency | Clarity up to 92%, glass-like appearance | Clarity up to 89%, slightly less clear |

| Weight | Lightweight, approximately 50% lighter than glass | Slightly heavier than acrylic, still lightweight |

| Cost | Moderate cost | Higher cost due to impact resistance |

| Common Applications | Outdoor signage, skylights, windows | Protective covers, greenhouse panels, safety glazing |

Acrylic vs Polycarbonate: Weatherproofing Performance

Acrylic offers superior UV resistance and maintains clarity longer under prolonged sun exposure, making it highly effective for weatherproofing applications. Polycarbonate, while more impact-resistant and flexible, tends to yellow and degrade faster when exposed to harsh weather conditions without additional coatings. For long-term outdoor use, acrylic provides more durable weatherproofing performance due to its resilience against UV radiation and environmental wear.

Durability in Harsh Weather: Acrylic and Polycarbonate Compared

Acrylic offers excellent resistance to UV rays and maintains clarity over time, making it a reliable choice for weatherproofing in harsh environments. Polycarbonate, known for its superior impact resistance and toughness, withstands extreme weather conditions without cracking or becoming brittle. Both materials provide durability, but polycarbonate outperforms acrylic in high-impact scenarios and extreme temperature fluctuations.

UV Resistance: Acrylic or Polycarbonate for Outdoor Use?

Acrylic offers superior UV resistance compared to polycarbonate, maintaining clarity and structural integrity without yellowing over extended outdoor exposure. Polycarbonate, while more impact-resistant, tends to degrade and discolor under prolonged UV radiation unless treated with specialized coatings. For long-term outdoor weatherproofing, acrylic is the preferred material due to its inherent UV stability and durability.

Impact Resistance and Weatherproofing: Which Material Wins?

Polycarbonate outperforms acrylic in impact resistance, offering up to 250 times more strength, making it ideal for harsh environments requiring robust protection. Both materials provide excellent weatherproofing, but polycarbonate's superior UV resistance and thermal stability ensure longer-lasting clarity and durability under extreme weather conditions. Acrylic remains a cost-effective choice with good weather resistance, yet polycarbonate ultimately wins for demanding impact and weatherproofing applications.

Temperature Tolerance: Acrylic vs Polycarbonate Analysis

Acrylic weatherproofing typically withstands temperatures up to 160degF (71degC), making it suitable for moderate climate conditions. Polycarbonate offers superior temperature tolerance, enduring heat up to 250degF (121degC) without deformation, which makes it ideal for high-temperature environments. This significant difference in temperature resistance impacts the longevity and performance of weatherproofing solutions in extreme weather applications.

Moisture Resistance: Acrylic Versus Polycarbonate

Acrylic offers excellent moisture resistance with a non-porous surface that prevents water absorption, making it ideal for prolonged outdoor exposure. Polycarbonate also provides good moisture resistance but is more prone to absorbing water vapor over time, which can lead to fogging or reduced clarity. For applications requiring superior long-term moisture protection, acrylic typically outperforms polycarbonate in maintaining transparency and structural integrity.

Longevity and Maintenance in Outdoor Conditions

Acrylic weatherproofing offers good UV resistance and maintains clarity over time, but it is more prone to scratching and may require frequent cleaning to preserve its appearance in outdoor conditions. Polycarbonate weatherproofing provides superior impact resistance and durability, with a higher tolerance to extreme weather, requiring less maintenance and offering longer service life in harsh environments. Choosing polycarbonate typically ensures extended longevity and reduced upkeep costs for outdoor applications compared to acrylic.

Cost-Effectiveness of Acrylic and Polycarbonate for Weatherproofing

Acrylic offers cost-effective weatherproofing with lower initial material costs and ease of installation, making it ideal for budget-conscious projects requiring moderate durability. Polycarbonate provides superior impact resistance and longevity but comes at a higher price point, increasing upfront expenses despite reduced maintenance over time. Evaluating project scope and environmental stressors determines whether the affordability of acrylic or the durability-driven investment in polycarbonate delivers better overall value.

Transparency and Clarity After Weather Exposure

Acrylic weatherproofing maintains exceptional transparency and clarity even after prolonged exposure to harsh weather conditions, resisting yellowing and cloudiness commonly caused by UV radiation. Polycarbonate, while highly impact-resistant, tends to degrade over time with exposure to sunlight, often developing a slight haze that reduces its optical clarity. Choosing acrylic ensures long-lasting visual performance in applications demanding clear, unobstructed views despite outdoor exposure.

Best Applications: Choosing Between Acrylic and Polycarbonate for Weatherproofing

Acrylic is ideal for weatherproofing applications requiring high clarity, UV resistance, and scratch resistance, making it perfect for skylights, windows, and outdoor signage where visual appeal is crucial. Polycarbonate excels in impact resistance and thermal insulation, suited for areas prone to hail, vandalism, or extreme weather, such as protective barriers, greenhouses, and industrial roofing. Selecting between acrylic and polycarbonate depends on balancing transparency and aesthetics with durability and impact strength in your weatherproofing project.

Acrylic Weatherproofing vs Polycarbonate Weatherproofing Infographic

materialdif.com

materialdif.com