Acrylic welding creates a strong, durable bond by melting the material edges together, resulting in a seamless joint ideal for structural applications. Solvent bonding, on the other hand, uses chemical solvents to dissolve and fuse the acrylic surfaces, providing a clear and smooth finish but with less mechanical strength compared to welding. Choosing between acrylic welding and solvent bonding depends on the required strength, appearance, and application needs of the acrylic pet components.

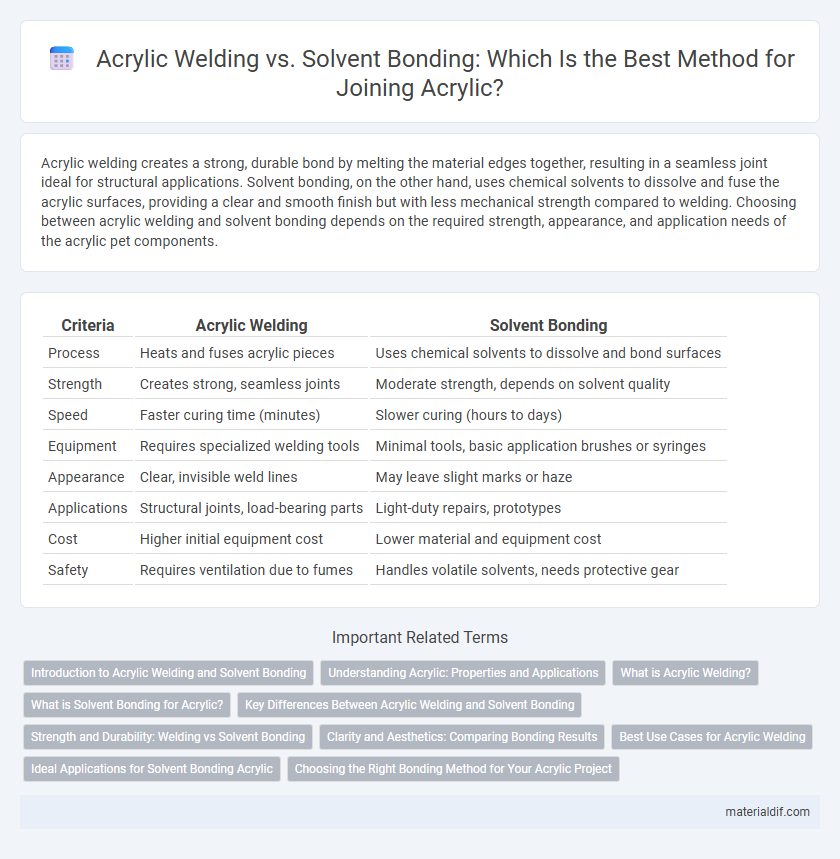

Table of Comparison

| Criteria | Acrylic Welding | Solvent Bonding |

|---|---|---|

| Process | Heats and fuses acrylic pieces | Uses chemical solvents to dissolve and bond surfaces |

| Strength | Creates strong, seamless joints | Moderate strength, depends on solvent quality |

| Speed | Faster curing time (minutes) | Slower curing (hours to days) |

| Equipment | Requires specialized welding tools | Minimal tools, basic application brushes or syringes |

| Appearance | Clear, invisible weld lines | May leave slight marks or haze |

| Applications | Structural joints, load-bearing parts | Light-duty repairs, prototypes |

| Cost | Higher initial equipment cost | Lower material and equipment cost |

| Safety | Requires ventilation due to fumes | Handles volatile solvents, needs protective gear |

Introduction to Acrylic Welding and Solvent Bonding

Acrylic welding involves using heat or ultrasonic energy to melt and fuse acrylic pieces, creating a strong, seamless joint ideal for structural applications. Solvent bonding uses chemical solvents that soften the acrylic surfaces, allowing them to dissolve and fuse upon evaporation, producing a clear, aesthetically smooth bond. Both methods offer distinct advantages in precision, strength, and appearance depending on the project requirements.

Understanding Acrylic: Properties and Applications

Acrylic welding creates strong, durable joints by melting and fusing acrylic pieces, making it ideal for structural applications requiring high mechanical strength and clarity. Solvent bonding uses chemical solvents to dissolve and fuse acrylic surfaces, offering precise, clean joints suitable for decorative or display purposes where optical clarity and smooth finishes are essential. Understanding acrylic's excellent impact resistance, clarity, and weatherability helps select the appropriate joining method based on application demands such as load-bearing capability or aesthetic requirements.

What is Acrylic Welding?

Acrylic welding is a fabrication process that uses heat to fuse acrylic sheets by melting their edges together, creating a strong and seamless joint. This method offers superior mechanical strength compared to solvent bonding, as it physically melds the material at a molecular level without introducing chemicals. Common techniques include hot gas welding and ultrasonic welding, which ensure durable connections ideal for structural applications.

What is Solvent Bonding for Acrylic?

Solvent bonding for acrylic involves using a chemical solvent to dissolve the surface layers of the acrylic sheets, allowing them to fuse together as the solvent evaporates and hardens. This technique creates a strong, clear, and seamless joint ideal for applications requiring high optical clarity and structural integrity. Compared to acrylic welding, solvent bonding typically offers cleaner edges and reduces the risk of thermal distortion.

Key Differences Between Acrylic Welding and Solvent Bonding

Acrylic welding uses heat to melt and fuse acrylic parts, creating a strong, seamless joint ideal for structural applications and high-stress environments. Solvent bonding relies on chemical solvents to dissolve the surface of acrylic components, producing a bonded joint by evaporating the solvent and allowing a molecular fusion at a lower temperature. Welding typically offers greater durability and clarity, while solvent bonding is preferred for simpler, less demanding assemblies due to its ease and lower equipment needs.

Strength and Durability: Welding vs Solvent Bonding

Acrylic welding creates a stronger and more durable bond by melting the acrylic surfaces together, resulting in a seamless joint that withstands stress and impacts better than solvent bonding. Solvent bonding relies on chemically softening the acrylic surfaces to fuse them, which can produce adequate strength but often results in joints prone to brittleness and lower resistance to mechanical forces over time. For applications demanding maximum structural integrity and longevity, welding typically outperforms solvent bonding in maintaining the strength and durability of acrylic components.

Clarity and Aesthetics: Comparing Bonding Results

Acrylic welding creates a seamless, crystal-clear joint by melting the plastic surfaces, preserving optical clarity and ensuring a smooth finish ideal for high-visibility applications. Solvent bonding chemically dissolves the acrylic edges, resulting in a slightly less transparent bond line that may show minor cloudiness or stress marks under close inspection. For projects prioritizing aesthetic perfection and clarity, acrylic welding typically delivers superior visual results with stronger, more invisible joints.

Best Use Cases for Acrylic Welding

Acrylic welding is best suited for applications requiring strong, durable joints that withstand mechanical stress, such as in structural components, automotive parts, and aerospace assemblies. This method provides superior clarity and seamless finishes, making it ideal for display cases, aquariums, and lighting fixtures. Unlike solvent bonding, acrylic welding avoids chemical weakening, resulting in enhanced joint integrity and long-term performance in demanding environments.

Ideal Applications for Solvent Bonding Acrylic

Solvent bonding acrylic is ideal for applications requiring strong, clear, and seamless joints, such as display cases, aquariums, and signage where optical clarity is crucial. This method chemically fuses acrylic sheets, providing durable bonds suited for indoor environments with minimal stress or impact. It excels in precision assembly tasks where maintaining surface aesthetics and avoiding visible joints are essential.

Choosing the Right Bonding Method for Your Acrylic Project

Acrylic welding provides a strong, durable joint by melting the acrylic edges together, ideal for structural applications requiring high strength and clarity. Solvent bonding uses chemical solvents to dissolve and fuse the acrylic surfaces, resulting in a smooth, nearly invisible seam perfect for aesthetic projects or thin sheets. Selecting the right bonding method depends on factors such as the project's strength requirements, visual finish, and material thickness, ensuring optimal performance and appearance for your acrylic fabrication.

Acrylic Welding vs Solvent Bonding Infographic

materialdif.com

materialdif.com