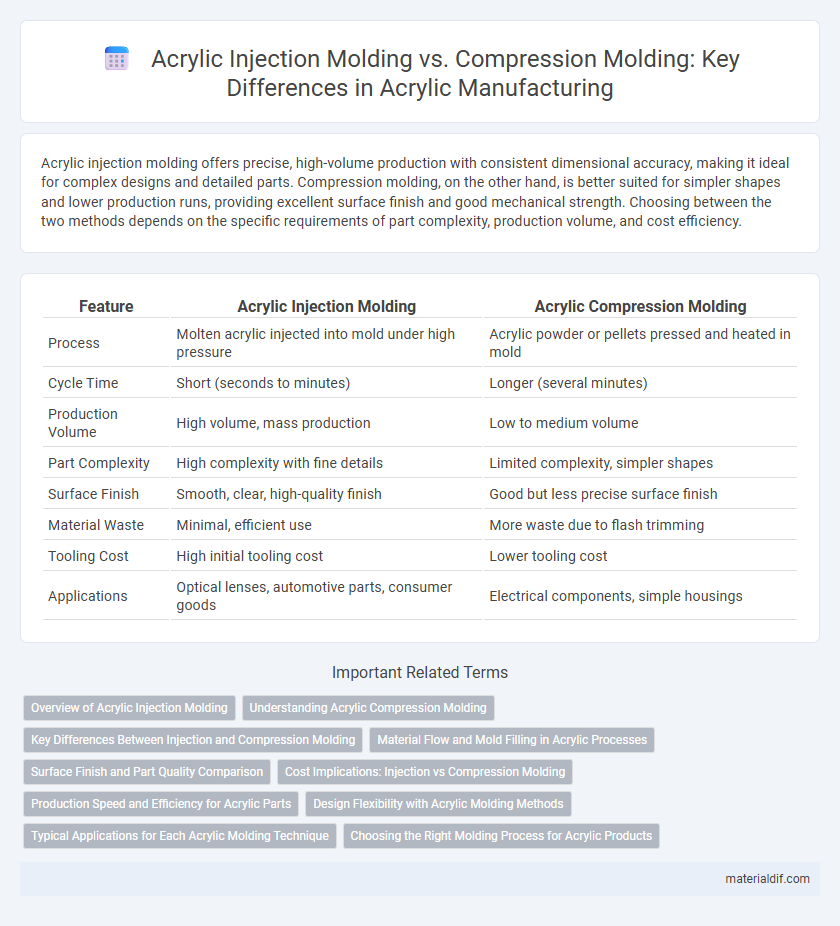

Acrylic injection molding offers precise, high-volume production with consistent dimensional accuracy, making it ideal for complex designs and detailed parts. Compression molding, on the other hand, is better suited for simpler shapes and lower production runs, providing excellent surface finish and good mechanical strength. Choosing between the two methods depends on the specific requirements of part complexity, production volume, and cost efficiency.

Table of Comparison

| Feature | Acrylic Injection Molding | Acrylic Compression Molding |

|---|---|---|

| Process | Molten acrylic injected into mold under high pressure | Acrylic powder or pellets pressed and heated in mold |

| Cycle Time | Short (seconds to minutes) | Longer (several minutes) |

| Production Volume | High volume, mass production | Low to medium volume |

| Part Complexity | High complexity with fine details | Limited complexity, simpler shapes |

| Surface Finish | Smooth, clear, high-quality finish | Good but less precise surface finish |

| Material Waste | Minimal, efficient use | More waste due to flash trimming |

| Tooling Cost | High initial tooling cost | Lower tooling cost |

| Applications | Optical lenses, automotive parts, consumer goods | Electrical components, simple housings |

Overview of Acrylic Injection Molding

Acrylic injection molding involves melting and injecting polymethyl methacrylate (PMMA) into precision molds to produce highly detailed, transparent components with excellent surface finish. This process offers faster cycle times and greater design flexibility compared to compression molding, making it ideal for high-volume production of complex acrylic parts. Enhanced dimensional accuracy and minimal post-processing requirements are key advantages that optimize manufacturing efficiency and product quality.

Understanding Acrylic Compression Molding

Acrylic compression molding involves placing acrylic resin into a heated mold cavity where pressure is applied to shape and cure the material, resulting in parts with excellent clarity and surface finish. This process is ideal for producing large, thick components with uniform density and minimal internal stress compared to injection molding. Understanding acrylic compression molding helps manufacturers optimize material properties and achieve superior optical performance for applications like lenses and display panels.

Key Differences Between Injection and Compression Molding

Acrylic injection molding involves melting acrylic pellets and injecting the molten material into a mold cavity under high pressure, enabling precise, complex shapes with tight tolerances and fast cycle times. Compression molding applies heat and pressure to a pre-measured acrylic charge placed in an open mold, ideal for larger, simpler shapes but with longer cooling times and less dimensional accuracy. Key differences include injection molding's superior surface finish and repeatability, while compression molding offers cost-effective production for low to medium volumes and thicker parts.

Material Flow and Mold Filling in Acrylic Processes

In acrylic injection molding, the material flow is highly controlled under pressure, allowing precise mold filling and complex part geometries with consistent surface finish. Compression molding of acrylic relies on the displacement of preheated material in a heated mold cavity, which can lead to less uniform filling and potential flow lines. Injection molding offers superior control of acrylic melt flow, reducing defects and ensuring detailed replication of mold features compared to compression molding.

Surface Finish and Part Quality Comparison

Acrylic injection molding produces parts with a smoother surface finish and higher dimensional accuracy due to the controlled injection of molten acrylic into precision molds. Compression molding typically results in slightly rougher surfaces and less consistent quality because the acrylic material is pressed into the mold rather than injected. For applications requiring superior clarity and fine details, injection molding is generally preferred over compression molding.

Cost Implications: Injection vs Compression Molding

Injection molding of acrylic typically incurs higher initial tooling costs due to complex molds but offers lower per-unit costs at high volumes, making it cost-effective for large production runs. Compression molding involves lower upfront expenses and simpler tooling, ideal for small batch or custom parts but results in higher per-unit costs as production scales. Selecting between injection and compression molding for acrylic depends on balancing budget constraints with anticipated production volume and part complexity.

Production Speed and Efficiency for Acrylic Parts

Acrylic injection molding offers significantly faster production speeds compared to compression molding, enabling high-volume output with consistent precision. The automated nature of injection molding reduces cycle times and labor costs, enhancing overall efficiency for complex acrylic parts. Compression molding, while suitable for lower volumes, often involves longer curing times and manual intervention, making it less efficient for large-scale acrylic manufacturing.

Design Flexibility with Acrylic Molding Methods

Acrylic injection molding offers greater design flexibility with the ability to produce complex shapes, fine details, and tight tolerances due to precise control over the molten material flow. Compression molding for acrylic is more suited to simpler geometries and larger parts but lacks the intricate detail achievable with injection molding. Choosing between these methods depends on the desired design complexity, with injection molding excelling in versatility for high-precision acrylic components.

Typical Applications for Each Acrylic Molding Technique

Acrylic injection molding is ideal for producing complex, high-precision parts like optical lenses, automotive components, and electronic housings due to its ability to create detailed and consistent shapes at high volumes. Compression molding suits larger, less intricate items such as acrylic sheets, signage, and display stands where molding pressure shapes the material with minimal waste. Each technique addresses specific manufacturing needs, balancing part complexity, production scale, and surface finish requirements.

Choosing the Right Molding Process for Acrylic Products

Acrylic injection molding offers high precision and complex geometries, making it ideal for mass-producing intricate acrylic parts with excellent surface finish and dimensional accuracy. Compression molding suits thicker, larger acrylic components where uniformity and strength are critical, often used for durable, heat-resistant products. Selecting the right molding process depends on product design complexity, volume requirements, and mechanical property priorities to optimize cost and performance in acrylic manufacturing.

Acrylic Injection Molding vs Compression Molding Infographic

materialdif.com

materialdif.com