Acrylic casting offers superior optical clarity and enhanced durability due to its slower polymerization process, making it ideal for applications requiring high-quality finishes and intricate shapes. Acrylic extrusion provides a cost-effective solution with consistent thickness and is well-suited for producing large volumes of standard sheets and profiles. Choosing between acrylic casting and extrusion depends on the specific requirements for strength, clarity, and production scale.

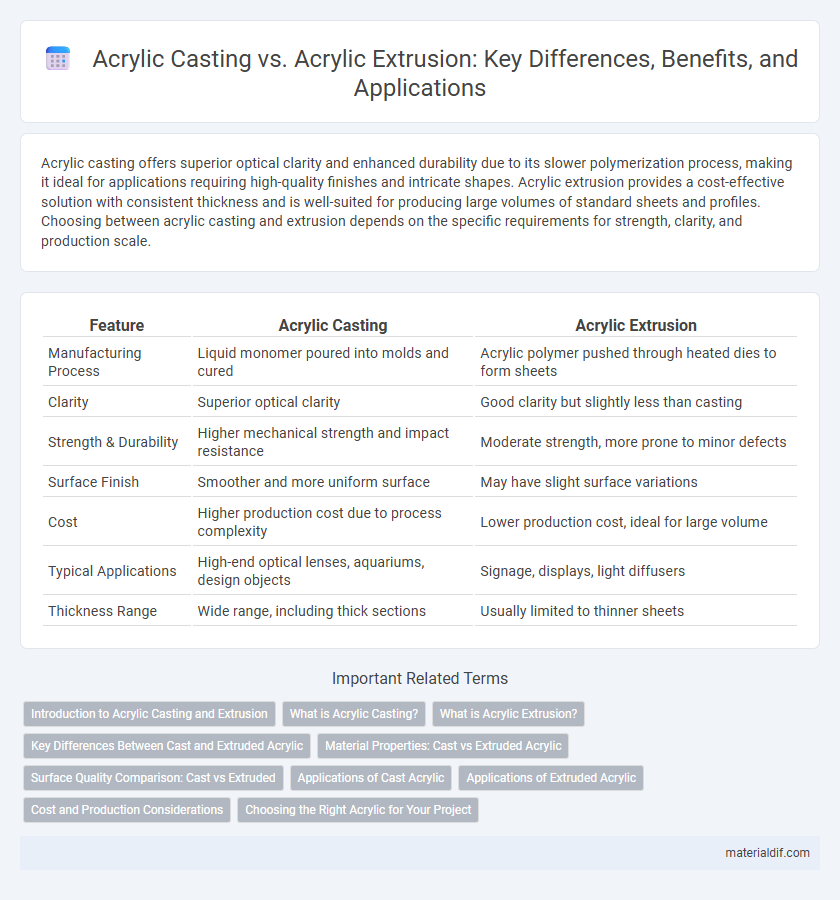

Table of Comparison

| Feature | Acrylic Casting | Acrylic Extrusion |

|---|---|---|

| Manufacturing Process | Liquid monomer poured into molds and cured | Acrylic polymer pushed through heated dies to form sheets |

| Clarity | Superior optical clarity | Good clarity but slightly less than casting |

| Strength & Durability | Higher mechanical strength and impact resistance | Moderate strength, more prone to minor defects |

| Surface Finish | Smoother and more uniform surface | May have slight surface variations |

| Cost | Higher production cost due to process complexity | Lower production cost, ideal for large volume |

| Typical Applications | High-end optical lenses, aquariums, design objects | Signage, displays, light diffusers |

| Thickness Range | Wide range, including thick sections | Usually limited to thinner sheets |

Introduction to Acrylic Casting and Extrusion

Acrylic casting involves pouring liquid monomer into molds where it polymerizes into solid sheets or custom shapes, offering superior clarity and a high molecular weight that enhances strength and durability. Acrylic extrusion produces sheets by forcing melted acrylic resin through a die, resulting in consistent thickness and smooth surfaces optimized for large-scale manufacturing. Cast acrylic excels in applications requiring excellent optical properties and resistance to solvents, while extruded acrylic is favored for cost-effective production and ease of fabrication.

What is Acrylic Casting?

Acrylic casting is a manufacturing process where liquid monomer is poured into a mold and polymerized, resulting in high-purity, optically clear acrylic with excellent strength and chemical resistance. This method allows for complex shapes and custom sizes, making it ideal for applications requiring superior clarity and durability, such as lenses and display cases. Compared to extrusion, cast acrylic exhibits enhanced scratch resistance and better thermal stability.

What is Acrylic Extrusion?

Acrylic extrusion is a manufacturing process where molten acrylic resin is forced through a shaped die to create continuous sheets or profiles with consistent thickness and smooth surfaces. This method offers cost-effective production for large volumes and allows for customized shapes and sizes, making it ideal for applications like signage, glazing, and light fixtures. Extruded acrylic typically has a lower cost and more flexibility compared to cast acrylic but may have slightly reduced optical clarity and chemical resistance.

Key Differences Between Cast and Extruded Acrylic

Cast acrylic is produced by pouring liquid acrylic into molds, resulting in higher optical clarity, superior chemical resistance, and enhanced impact strength. Extruded acrylic is made by continuously pushing softened acrylic through a machine, offering consistent thickness, better dimensional stability, and lower cost. Cast acrylic is preferred for applications requiring durability and clarity, while extruded acrylic suits large-scale projects needing uniformity and affordability.

Material Properties: Cast vs Extruded Acrylic

Cast acrylic exhibits superior optical clarity, higher chemical resistance, and greater strength compared to extruded acrylic, making it ideal for applications requiring precision and durability. Extruded acrylic, while less expensive and easier to fabricate, tends to have lower molecular weight, resulting in reduced impact resistance and higher susceptibility to stress cracking. The differences in polymerization processes directly influence the material's thermal stability and surface hardness, with cast acrylic outperforming extruded variants in demanding environments.

Surface Quality Comparison: Cast vs Extruded

Acrylic casting produces sheets with superior optical clarity and a smoother surface finish compared to extrusion, resulting in fewer internal stresses and a more consistent texture. Cast acrylic offers enhanced scratch resistance and can achieve higher polish levels, making it ideal for applications demanding high aesthetic appeal. Extruded acrylic, while more cost-effective, typically exhibits minor surface imperfections and lower UV stability, which can affect long-term clarity and durability.

Applications of Cast Acrylic

Cast acrylic is favored for applications requiring superior optical clarity, high impact resistance, and excellent weatherability, making it ideal for aquariums, display cases, and medical devices. Its enhanced chemical resistance and ability to be machined with precision suit it for aerospace components and automotive parts. Unlike extruded acrylic, cast acrylic offers greater dimensional stability and thermal resistance, crucial for demanding industrial and decorative uses.

Applications of Extruded Acrylic

Extruded acrylic is widely used in applications such as signage, displays, and protective barriers due to its cost-effectiveness and consistent thickness. Its excellent clarity and impact resistance make it ideal for point-of-sale displays, light diffusers, and architectural glazing. Unlike cast acrylic, extruded sheets are better suited for large-scale manufacturing where uniformity and ease of fabrication are crucial.

Cost and Production Considerations

Acrylic casting generally incurs higher costs due to its labor-intensive process and slower production rates compared to acrylic extrusion, which offers faster and more cost-effective mass production. The casting method provides superior clarity and strength, making it ideal for custom or high-performance applications despite the increased expense. Extrusion is preferred for large-volume projects requiring consistent profiles and lower material waste, offering economical benefits in large-scale manufacturing.

Choosing the Right Acrylic for Your Project

Acrylic casting provides superior clarity, durability, and the ability to create thick, complex shapes, making it ideal for high-end displays and signage requiring precision and strength. Acrylic extrusion offers cost-effective production with consistent thickness and smooth surfaces, suited for large-scale projects or applications where uniformity and ease of fabrication are priorities. Selecting the right acrylic involves balancing factors like clarity, mechanical properties, production volume, and budget to ensure optimal performance and aesthetics.

Acrylic Casting vs Acrylic Extrusion Infographic

materialdif.com

materialdif.com