Acrylic laminating involves bonding multiple acrylic layers to enhance durability and optical clarity, making it ideal for protective screens and signage. Acrylic fabrication refers to shaping and cutting solid acrylic sheets into various forms, commonly used for custom displays and decorative elements. Choosing between laminating and fabrication depends on the specific application requirements such as strength, transparency, and design complexity.

Table of Comparison

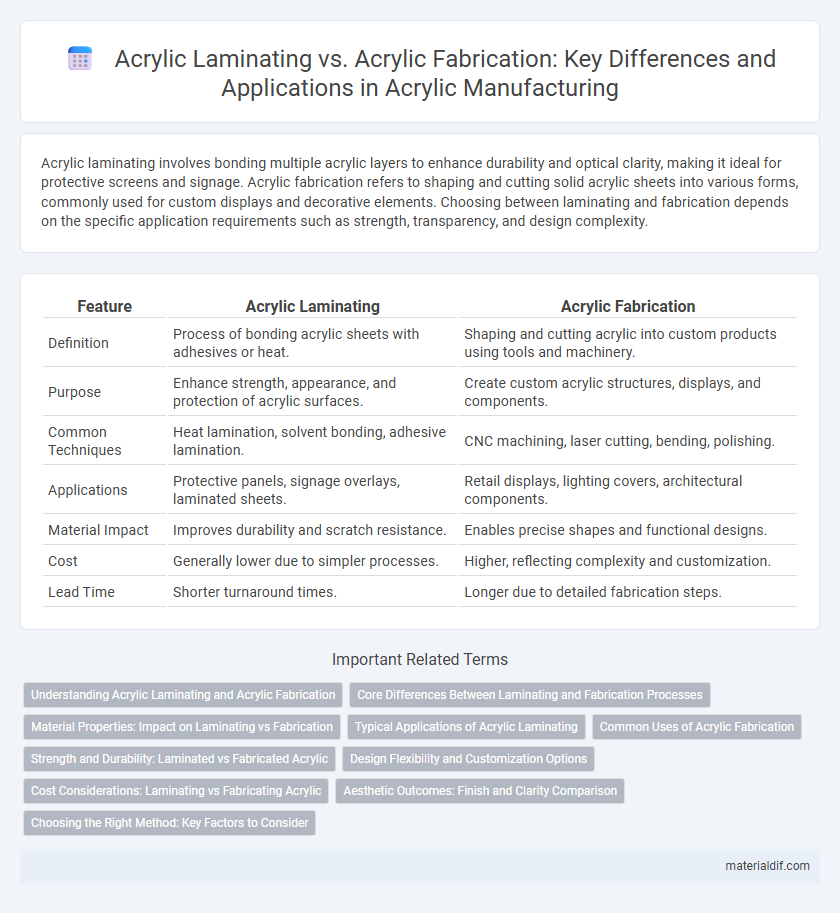

| Feature | Acrylic Laminating | Acrylic Fabrication |

|---|---|---|

| Definition | Process of bonding acrylic sheets with adhesives or heat. | Shaping and cutting acrylic into custom products using tools and machinery. |

| Purpose | Enhance strength, appearance, and protection of acrylic surfaces. | Create custom acrylic structures, displays, and components. |

| Common Techniques | Heat lamination, solvent bonding, adhesive lamination. | CNC machining, laser cutting, bending, polishing. |

| Applications | Protective panels, signage overlays, laminated sheets. | Retail displays, lighting covers, architectural components. |

| Material Impact | Improves durability and scratch resistance. | Enables precise shapes and functional designs. |

| Cost | Generally lower due to simpler processes. | Higher, reflecting complexity and customization. |

| Lead Time | Shorter turnaround times. | Longer due to detailed fabrication steps. |

Understanding Acrylic Laminating and Acrylic Fabrication

Acrylic laminating involves bonding multiple acrylic sheets or combining acrylic with other materials using adhesives or heat to create a single, durable surface with enhanced strength and optical clarity. Acrylic fabrication encompasses processes like cutting, shaping, bending, and assembling acrylic sheets into finished products or components tailored for specific applications. Understanding these distinctions helps in selecting the right approach for projects requiring customized acrylic solutions or improved material performance.

Core Differences Between Laminating and Fabrication Processes

Acrylic laminating involves bonding thin sheets of acrylic to various substrates using adhesives and heat, enhancing surface durability and aesthetic appeal. Acrylic fabrication encompasses cutting, shaping, and assembling acrylic sheets into functional or decorative components, often through machining, bending, and polishing techniques. The core difference lies in laminating's focus on layering and surface protection, while fabrication emphasizes structural modification and custom design.

Material Properties: Impact on Laminating vs Fabrication

Acrylic laminating preserves the material's clarity and enhances surface durability by bonding thin acrylic sheets together, making it ideal for applications requiring uniform thickness and impact resistance. In contrast, acrylic fabrication involves cutting, shaping, and assembling solid acrylic sheets, which may alter stress distribution and optical properties depending on the machining processes used. The inherent chemical resistance and rigidity of acrylic influence both laminating and fabrication techniques, dictating the choice based on the required mechanical strength and aesthetic finish.

Typical Applications of Acrylic Laminating

Acrylic laminating is commonly used in applications requiring enhanced durability and aesthetic appeal, such as protective displays, signage, and picture framing. This process involves bonding multiple acrylic layers to improve scratch resistance, UV protection, and optical clarity. In contrast, acrylic fabrication typically focuses on shaping and cutting acrylic sheets for structural or decorative components in sectors like architecture and automotive.

Common Uses of Acrylic Fabrication

Acrylic fabrication involves shaping and assembling acrylic sheets into custom products such as displays, signage, and protective barriers, widely used in retail, medical, and architectural applications. This process enables precise cutting, bending, and joining to create durable, clear, and lightweight structures tailored to specific design requirements. Common uses include point-of-sale displays, aquarium tanks, lighting fixtures, and furniture components where both aesthetic appeal and functional strength are essential.

Strength and Durability: Laminated vs Fabricated Acrylic

Acrylic laminating enhances strength by bonding multiple layers, creating a thicker, more impact-resistant surface ideal for high-stress applications. Fabricated acrylic retains the inherent durability of a single sheet but may be more prone to cracking or scratching under heavy use. Laminated acrylic typically offers superior long-term durability and resistance to wear compared to fabricated acrylic components.

Design Flexibility and Customization Options

Acrylic laminating offers enhanced design flexibility by allowing multiple layers to be bonded together, creating unique textures, colors, and finishes that suit bespoke projects. Acrylic fabrication involves cutting, shaping, and assembling solid acrylic sheets, providing precise customization for structural and functional designs. Both methods enable tailored solutions, but laminating excels in aesthetic versatility while fabrication focuses on structural adaptability.

Cost Considerations: Laminating vs Fabricating Acrylic

Acrylic laminating typically incurs lower upfront costs due to simplified processes and minimal equipment requirements, making it ideal for budget-conscious projects. Acrylic fabrication involves cutting, shaping, and assembling, resulting in higher labor and machinery expenses but offering greater customization and durability. Evaluating project needs against cost differences between laminating and fabricating acrylic ensures informed financial decisions for quality and functionality.

Aesthetic Outcomes: Finish and Clarity Comparison

Acrylic laminating involves bonding thin acrylic sheets to create smoother, uniform surfaces with enhanced clarity and UV resistance, resulting in a high-gloss, glass-like finish ideal for display applications. Acrylic fabrication, including cutting, shaping, and polishing, offers precise custom forms but may exhibit slight edge imperfections and surface variations affecting overall transparency. Laminating typically produces superior aesthetic outcomes in finish smoothness and optical clarity, while fabrication excels in structural versatility and tailored design.

Choosing the Right Method: Key Factors to Consider

Choosing between acrylic laminating and acrylic fabrication depends primarily on the project's durability requirements and aesthetic goals. Acrylic laminating enhances surface protection and visual appeal by bonding layers for increased strength and clarity, ideal for signage and decorative panels. Acrylic fabrication involves cutting, shaping, and assembling, offering greater customization and structural integrity suited for functional components and complex designs.

Acrylic Laminating vs Acrylic Fabrication Infographic

materialdif.com

materialdif.com