Acrylic sheets offer excellent clarity and impact resistance, making them ideal for general applications where durability is essential. Cast acrylic provides superior optical clarity and chemical resistance due to its manufacturing process, which results in a stronger and more scratch-resistant surface. Choosing between acrylic sheet and cast acrylic depends on the specific requirements of strength, clarity, and usage environment.

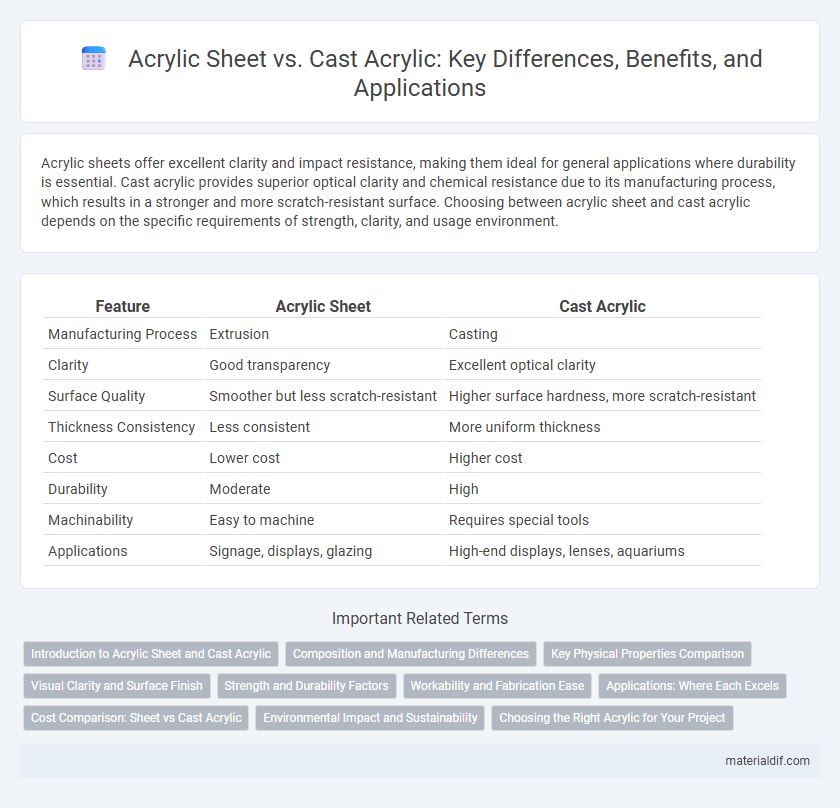

Table of Comparison

| Feature | Acrylic Sheet | Cast Acrylic |

|---|---|---|

| Manufacturing Process | Extrusion | Casting |

| Clarity | Good transparency | Excellent optical clarity |

| Surface Quality | Smoother but less scratch-resistant | Higher surface hardness, more scratch-resistant |

| Thickness Consistency | Less consistent | More uniform thickness |

| Cost | Lower cost | Higher cost |

| Durability | Moderate | High |

| Machinability | Easy to machine | Requires special tools |

| Applications | Signage, displays, glazing | High-end displays, lenses, aquariums |

Introduction to Acrylic Sheet and Cast Acrylic

Acrylic sheet is a versatile thermoplastic material widely used for its clarity, impact resistance, and weatherability. Cast acrylic is produced by pouring liquid monomer into molds, resulting in a denser, clearer, and more scratch-resistant product compared to extrusion-based acrylic sheets. These differences make cast acrylic ideal for applications requiring superior optical clarity and strength, while standard acrylic sheets offer cost-effective versatility.

Composition and Manufacturing Differences

Acrylic sheets are typically produced through a continuous polymerization process, resulting in a uniform structure with consistent thickness, while cast acrylic is manufactured by pouring liquid monomer into molds, creating a denser and more rigid material. The composition of cast acrylic often includes higher molecular weight polymers, giving it superior optical clarity and chemical resistance compared to extruded acrylic sheets. These manufacturing differences influence their mechanical properties, with cast acrylic exhibiting better durability and machining flexibility, making it ideal for precision applications.

Key Physical Properties Comparison

Acrylic sheets are typically extruded, resulting in a material with uniform thickness and moderate impact resistance, while cast acrylic is produced by casting liquid monomer into a mold, offering superior clarity and higher scratch resistance. Cast acrylic exhibits greater hardness and better chemical resistance than extruded acrylic sheets, making it ideal for applications requiring durability and visual excellence. Both materials provide excellent UV resistance, but cast acrylic's enhanced thermal stability allows it to withstand higher temperatures without deformation.

Visual Clarity and Surface Finish

Cast acrylic offers superior visual clarity with fewer impurities and greater light transmission compared to acrylic sheet, making it ideal for applications requiring high optical quality. Its surface finish is smoother and more polished due to the casting process, resulting in a more aesthetically pleasing and durable appearance. Acrylic sheets, typically produced by extrusion, may have minor surface imperfections and slightly reduced clarity but are more cost-effective for general use.

Strength and Durability Factors

Cast acrylic offers superior strength and durability compared to acrylic sheets due to its manufacturing process, which involves pouring liquid acrylic into molds, resulting in a denser and more impact-resistant material. Acrylic sheets, produced through extrusion, are more prone to scratches and may have less resistance to UV light and chemicals over time. For applications requiring long-term durability and higher mechanical strength, cast acrylic is the preferred choice.

Workability and Fabrication Ease

Acrylic sheet excels in workability due to its consistent thickness and uniformity, allowing for precise cutting, drilling, and thermoforming in various fabrication processes. Cast acrylic offers superior impact resistance and a smoother surface finish but is generally harder to machine and polish compared to extruded acrylic sheets. Fabricators prefer acrylic sheets for projects requiring tight tolerances and easy manipulation, while cast acrylic is favored for applications needing enhanced optical clarity and durability.

Applications: Where Each Excels

Acrylic sheets, known for their affordability and ease of fabrication, excel in applications such as signage, display cases, and skylights where lightweight and cost-effective solutions are essential. Cast acrylic offers superior optical clarity, higher chemical resistance, and enhanced impact strength, making it ideal for precision applications like medical devices, aquariums, and high-end retail displays. Choosing between acrylic sheet and cast acrylic depends on specific performance requirements and environmental conditions of the intended application.

Cost Comparison: Sheet vs Cast Acrylic

Acrylic sheets generally cost less than cast acrylic due to their manufacturing process, which involves extrusion, making them more suitable for budget-conscious projects. Cast acrylic, formed through a slower liquid polymerization process, offers superior optical clarity and durability but comes at a higher price point. When comparing costs, extruded acrylic sheets provide an economical option for large-scale applications, while cast acrylic's premium cost is justified by enhanced performance and finish quality.

Environmental Impact and Sustainability

Cast acrylic sheets generally have a lower environmental impact than standard acrylic sheets due to their longer lifespan and higher resistance to yellowing and cracking, which reduces the frequency of replacement. Manufactured through a slower polymerization process, cast acrylic uses fewer additives and generates less waste, enhancing sustainability. Recycling options for cast acrylic are more viable, as its purer composition facilitates processing and reusability compared to extruded acrylic sheets.

Choosing the Right Acrylic for Your Project

Choosing the right acrylic for your project depends on factors like application requirements, durability, and cost. Acrylic sheet offers excellent impact resistance and is more affordable, making it ideal for general-purpose use and DIY projects. Cast acrylic, known for superior optical clarity and machinability, suits high-precision applications such as display cases, aquariums, and medical devices.

Acrylic Sheet vs Cast Acrylic Infographic

materialdif.com

materialdif.com