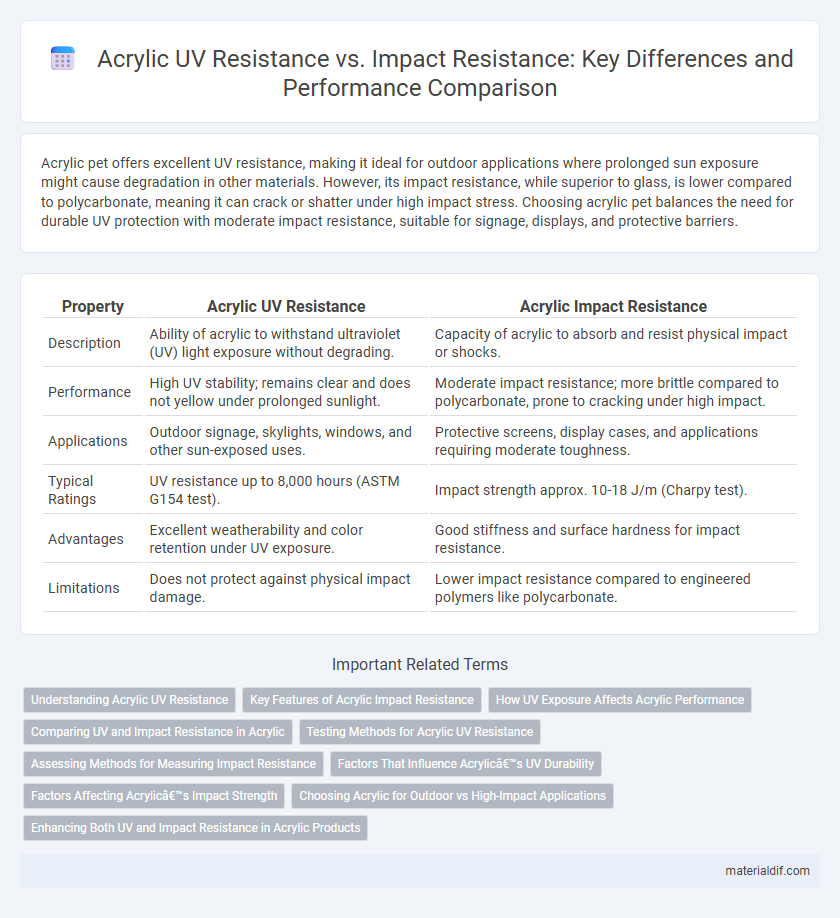

Acrylic pet offers excellent UV resistance, making it ideal for outdoor applications where prolonged sun exposure might cause degradation in other materials. However, its impact resistance, while superior to glass, is lower compared to polycarbonate, meaning it can crack or shatter under high impact stress. Choosing acrylic pet balances the need for durable UV protection with moderate impact resistance, suitable for signage, displays, and protective barriers.

Table of Comparison

| Property | Acrylic UV Resistance | Acrylic Impact Resistance |

|---|---|---|

| Description | Ability of acrylic to withstand ultraviolet (UV) light exposure without degrading. | Capacity of acrylic to absorb and resist physical impact or shocks. |

| Performance | High UV stability; remains clear and does not yellow under prolonged sunlight. | Moderate impact resistance; more brittle compared to polycarbonate, prone to cracking under high impact. |

| Applications | Outdoor signage, skylights, windows, and other sun-exposed uses. | Protective screens, display cases, and applications requiring moderate toughness. |

| Typical Ratings | UV resistance up to 8,000 hours (ASTM G154 test). | Impact strength approx. 10-18 J/m (Charpy test). |

| Advantages | Excellent weatherability and color retention under UV exposure. | Good stiffness and surface hardness for impact resistance. |

| Limitations | Does not protect against physical impact damage. | Lower impact resistance compared to engineered polymers like polycarbonate. |

Understanding Acrylic UV Resistance

Acrylic UV resistance refers to the material's ability to withstand prolonged exposure to ultraviolet light without yellowing, cracking, or degrading, which is essential for outdoor applications. High-quality acrylics often incorporate UV stabilizers that enhance durability and maintain clarity despite continuous sunlight exposure. Understanding these properties ensures effective selection of acrylic sheets for environments exposed to intense UV radiation.

Key Features of Acrylic Impact Resistance

Acrylic is known for its excellent UV resistance, maintaining clarity and color without yellowing over prolonged sun exposure. Acrylic impact resistance, a key feature, provides high durability and toughness, making it less prone to cracking or shattering under pressure compared to standard glass. This impact resistance is crucial for applications requiring both transparency and enhanced safety, such as protective barriers and outdoor signage.

How UV Exposure Affects Acrylic Performance

Acrylic exhibits strong UV resistance, maintaining clarity and structural integrity under prolonged sunlight exposure, making it ideal for outdoor applications like skylights and signage. However, extended UV exposure can cause surface yellowing and brittleness, which reduces impact resistance and increases the likelihood of cracks or fractures upon impact. Balancing UV resistance and impact resistance is crucial for applications requiring both durability and weatherproofing.

Comparing UV and Impact Resistance in Acrylic

Acrylic offers superior UV resistance compared to many other plastics, maintaining clarity and structural integrity when exposed to sunlight for prolonged periods. While acrylic excels in resisting UV degradation, its impact resistance is lower than that of polycarbonate, making it more prone to cracking or shattering under high-impact conditions. Choosing between UV resistance and impact resistance in acrylic hinges on the application requirements, where durability against sunlight is prioritized over toughness.

Testing Methods for Acrylic UV Resistance

Acrylic UV resistance is commonly evaluated using accelerated weathering tests such as the QUV and Xenon arc tests, which simulate long-term exposure to sunlight and measure changes in material properties including color fading and structural integrity. These standardized methods follow ASTM D4329 and ISO 4892 protocols to assess degradation under UV radiation. While UV resistance testing focuses on photochemical stability, impact resistance evaluation employs mechanical impact tests like the Charpy or Izod tests to measure acrylic's ability to withstand sudden forces.

Assessing Methods for Measuring Impact Resistance

Acrylic UV resistance is primarily measured using accelerated weathering tests that simulate prolonged sun exposure, focusing on color retention and surface integrity. For assessing acrylic impact resistance, standardized impact tests such as the Izod or Charpy test are employed to quantify the material's ability to withstand sudden force or shock. These methods provide critical data for selecting acrylic grades suitable for applications requiring both durability and UV stability.

Factors That Influence Acrylic’s UV Durability

Acrylic's UV resistance is primarily influenced by factors such as the presence of UV stabilizers, the thickness of the material, and its surface treatments, which help prevent degradation and yellowing over time. In contrast, acrylic impact resistance depends on its molecular structure, polymer cross-linking, and the incorporation of impact modifiers to enhance toughness and prevent cracking. Understanding these distinct properties enables better selection of acrylic types for applications requiring long-term UV durability or high-impact performance.

Factors Affecting Acrylic’s Impact Strength

Acrylic's impact resistance is primarily influenced by factors such as molecular weight, thickness, and the presence of additives or plasticizers, which enhance toughness and reduce brittleness. UV resistance in acrylic helps prevent surface degradation and discoloration but does not significantly improve impact strength; prolonged UV exposure can actually weaken acrylic and reduce its ability to absorb shocks. Proper formulation and controlled processing conditions are crucial for maximizing acrylic's impact strength, while UV stabilizers ensure long-term durability against environmental damage.

Choosing Acrylic for Outdoor vs High-Impact Applications

Acrylic UV resistance excels in outdoor applications by maintaining clarity and color stability under prolonged sun exposure, making it ideal for windows, skylights, and signage. In contrast, acrylic impact resistance is crucial for high-impact environments such as protective barriers and safety shields, where durability and shatter resistance are necessary. Selecting acrylic for outdoor use prioritizes UV resistance, while high-impact applications demand acrylic formulations that enhance toughness and hardness.

Enhancing Both UV and Impact Resistance in Acrylic Products

Enhancing both UV and impact resistance in acrylic products involves incorporating advanced additives such as UV stabilizers and impact modifiers that improve durability without compromising clarity. UV inhibitors prevent degradation from prolonged sun exposure, while impact modifiers increase toughness to withstand physical stress and reduce brittleness. Combining these treatments ensures acrylic materials maintain optical clarity and mechanical strength in harsh outdoor environments, extending product lifespan significantly.

Acrylic UV Resistance vs Acrylic Impact Resistance Infographic

materialdif.com

materialdif.com