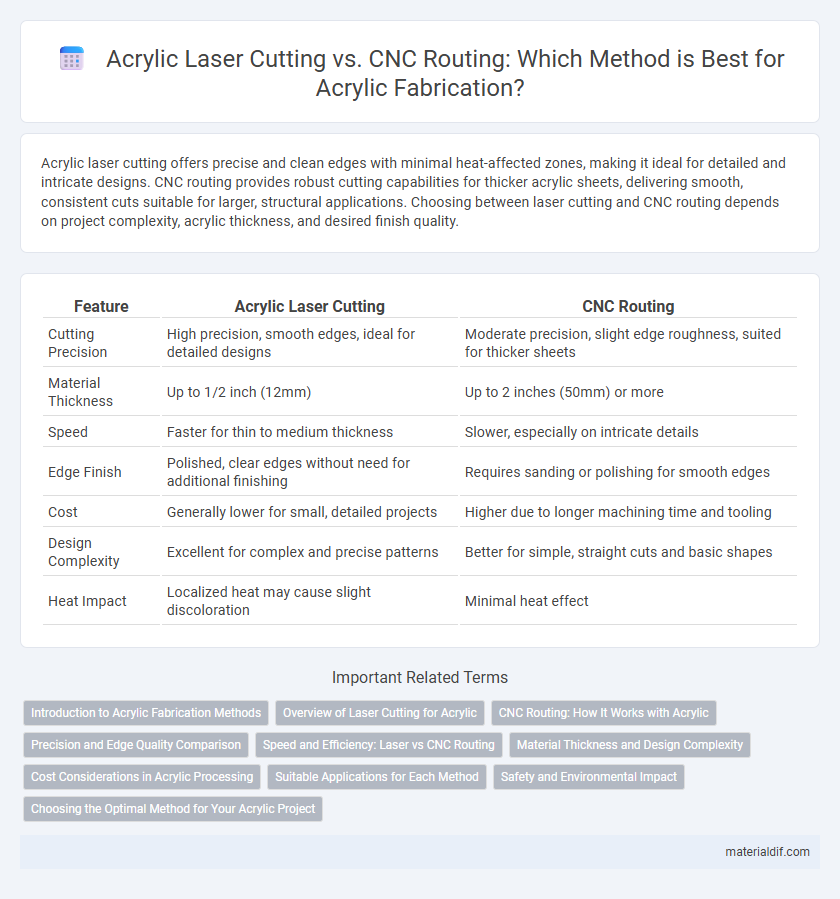

Acrylic laser cutting offers precise and clean edges with minimal heat-affected zones, making it ideal for detailed and intricate designs. CNC routing provides robust cutting capabilities for thicker acrylic sheets, delivering smooth, consistent cuts suitable for larger, structural applications. Choosing between laser cutting and CNC routing depends on project complexity, acrylic thickness, and desired finish quality.

Table of Comparison

| Feature | Acrylic Laser Cutting | CNC Routing |

|---|---|---|

| Cutting Precision | High precision, smooth edges, ideal for detailed designs | Moderate precision, slight edge roughness, suited for thicker sheets |

| Material Thickness | Up to 1/2 inch (12mm) | Up to 2 inches (50mm) or more |

| Speed | Faster for thin to medium thickness | Slower, especially on intricate details |

| Edge Finish | Polished, clear edges without need for additional finishing | Requires sanding or polishing for smooth edges |

| Cost | Generally lower for small, detailed projects | Higher due to longer machining time and tooling |

| Design Complexity | Excellent for complex and precise patterns | Better for simple, straight cuts and basic shapes |

| Heat Impact | Localized heat may cause slight discoloration | Minimal heat effect |

Introduction to Acrylic Fabrication Methods

Acrylic laser cutting offers precise, clean edges ideal for intricate designs and detailed work, utilizing a focused laser beam to vaporize material with minimal heat-affected zones. CNC routing involves mechanically engraving or cutting acrylic sheets, providing efficient processing for thicker materials and complex, larger-scale projects with varying depths. Both methods are essential in acrylic fabrication, selected based on project requirements such as detail precision, material thickness, and production volume.

Overview of Laser Cutting for Acrylic

Laser cutting for acrylic offers high precision and clean edges, utilizing a focused laser beam to vaporize or melt material along the cutting path. This process produces detailed cuts without mechanical stress, making it ideal for intricate designs and fine details in signage, displays, and decorative items. Compared to CNC routing, laser cutting minimizes material waste and reduces the need for post-processing, resulting in a smooth, polished finish directly from the machine.

CNC Routing: How It Works with Acrylic

CNC routing works by using computer-controlled rotary cutting tools to precisely shape acrylic sheets into intricate designs, allowing for rapid and accurate production. The router follows programmed paths to carve, drill, and cut acrylic with smooth edges, minimizing heat buildup and reducing the risk of material warping or melting. This method is ideal for thick acrylic panels and complex 3D shapes, offering high versatility and consistent quality in fabrication.

Precision and Edge Quality Comparison

Acrylic laser cutting offers superior precision with focused laser beams enabling intricate designs and smooth, polished edges that require minimal post-processing. CNC routing provides strong mechanical cutting suited for thicker acrylic sheets but may produce rougher edges necessitating additional finishing. The choice depends on project demands for edge quality and detail accuracy, with laser cutting favored for fine, high-precision applications.

Speed and Efficiency: Laser vs CNC Routing

Laser cutting acrylic offers unmatched speed and precision, allowing intricate designs to be completed swiftly with minimal material waste. CNC routing, while reliable for thicker acrylic sheets, generally operates at slower speeds due to its mechanical cutting process, impacting overall efficiency. For high-volume production and detailed cuts, laser cutting proves significantly more efficient compared to CNC routing.

Material Thickness and Design Complexity

Acrylic laser cutting excels in handling thinner sheets up to 1/2 inch with exceptional precision and intricate detail, making it ideal for complex designs featuring fine curves and detailed patterns. CNC routing effectively processes thicker acrylic materials, commonly ranging from 1/2 inch to 2 inches or more, and accommodates robust, less intricate designs that require depth and durability. Selecting between laser cutting and CNC routing depends primarily on the acrylic's thickness and the complexity of the design, balancing precision with material capabilities.

Cost Considerations in Acrylic Processing

Acrylic laser cutting generally offers lower initial setup costs due to minimal tooling requirements compared to CNC routing, which involves higher expenses for custom bits and machine maintenance. Laser cutting provides precise, clean edges with faster turnaround times, reducing labor costs in acrylic processing. CNC routing, while more expensive upfront, is cost-effective for larger production runs or thicker acrylic sheets, balancing material waste and operational efficiency.

Suitable Applications for Each Method

Acrylic laser cutting excels in producing intricate designs, fine details, and smooth edges, making it ideal for signage, decorative items, and precise prototypes. CNC routing suits applications requiring thicker acrylic materials with deeper cuts or complex 3D shaping, commonly used in furniture components, automotive parts, and industrial panels. Selecting between these methods depends on material thickness, design complexity, and desired finish quality.

Safety and Environmental Impact

Acrylic laser cutting produces minimal dust and fumes, which can be effectively managed with proper ventilation and filtration systems, reducing health risks compared to CNC routing that generates acrylic chips and sharp debris requiring careful handling. Both methods require protective equipment, but laser cutting's sealed environment and fewer airborne particles enhance operator safety. Environmentally, laser cutting consumes less material waste due to precision and produces fewer physical residues, whereas CNC routing generates more scrap acrylic, impacting disposal and recycling efforts.

Choosing the Optimal Method for Your Acrylic Project

Laser cutting acrylic offers high precision and clean edges, making it ideal for detailed, intricate designs and thin sheets. CNC routing is better suited for thicker acrylic and projects requiring deeper cuts or complex 3D shapes, providing versatility in material thickness and dimensional depth. Selecting the optimal method depends on the acrylic's thickness, design complexity, and desired edge finish for achieving the best project outcome.

Acrylic Laser Cutting vs CNC Routing Infographic

materialdif.com

materialdif.com