Acrylic fabrication offers superior clarity and scratch resistance, making it ideal for display cases and signs requiring crystal-clear transparency. Polycarbonate fabrication provides exceptional impact resistance and durability, suitable for applications demanding high strength and toughness, such as protective gear and safety shields. Choosing between acrylic and polycarbonate depends on balancing optical clarity with impact performance requirements.

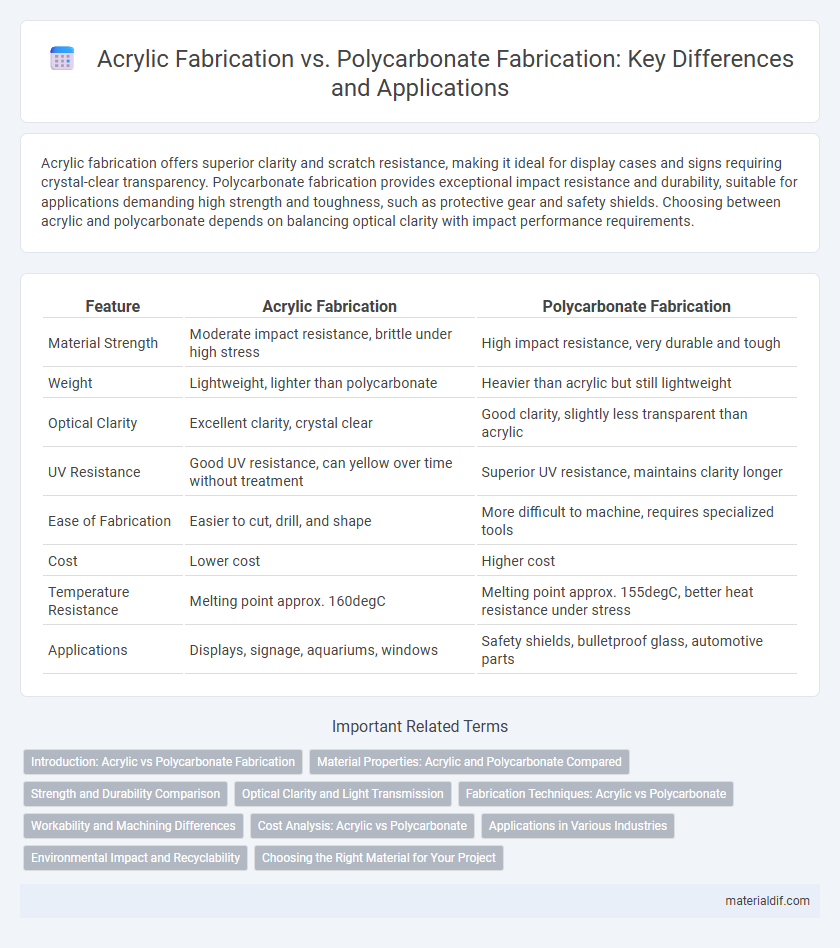

Table of Comparison

| Feature | Acrylic Fabrication | Polycarbonate Fabrication |

|---|---|---|

| Material Strength | Moderate impact resistance, brittle under high stress | High impact resistance, very durable and tough |

| Weight | Lightweight, lighter than polycarbonate | Heavier than acrylic but still lightweight |

| Optical Clarity | Excellent clarity, crystal clear | Good clarity, slightly less transparent than acrylic |

| UV Resistance | Good UV resistance, can yellow over time without treatment | Superior UV resistance, maintains clarity longer |

| Ease of Fabrication | Easier to cut, drill, and shape | More difficult to machine, requires specialized tools |

| Cost | Lower cost | Higher cost |

| Temperature Resistance | Melting point approx. 160degC | Melting point approx. 155degC, better heat resistance under stress |

| Applications | Displays, signage, aquariums, windows | Safety shields, bulletproof glass, automotive parts |

Introduction: Acrylic vs Polycarbonate Fabrication

Acrylic fabrication offers superior clarity and UV resistance, making it ideal for outdoor signage and displays, while polycarbonate fabrication excels in impact resistance and heat tolerance, suitable for protective barriers and industrial uses. Acrylic sheets are easier to cut and shape, allowing for intricate designs, whereas polycarbonate demands more advanced tools due to its toughness. The choice between acrylic and polycarbonate fabrication depends on application-specific requirements such as durability, transparency, and environmental exposure.

Material Properties: Acrylic and Polycarbonate Compared

Acrylic fabrication offers superior optical clarity with a light transmittance of up to 92%, making it ideal for applications requiring high transparency and scratch resistance. Polycarbonate fabrication provides exceptional impact resistance, being 250 times stronger than glass, which makes it suitable for safety and security uses. Both materials differ significantly in thermal resistance, with polycarbonate capable of withstanding higher temperatures up to 270degF, while acrylic softens at around 160degF.

Strength and Durability Comparison

Acrylic fabrication offers moderate strength and good resistance to UV light and weathering, making it suitable for applications requiring clear, rigid panels that maintain clarity over time. Polycarbonate fabrication provides superior impact resistance and higher tensile strength, which enhances durability in demanding environments prone to physical stress or impact. While acrylic is more scratch-resistant, polycarbonate's exceptional toughness and flexibility make it ideal for high-strength, durable solutions such as safety glazing and protective barriers.

Optical Clarity and Light Transmission

Acrylic fabrication offers superior optical clarity with light transmission rates around 92%, providing a crystal-clear appearance ideal for display and glazing applications. Polycarbonate fabrication, though slightly lower in clarity with light transmission near 88%, excels in impact resistance and durability for protective uses. The choice between acrylic and polycarbonate materials depends on prioritizing maximum transparency versus enhanced toughness.

Fabrication Techniques: Acrylic vs Polycarbonate

Acrylic fabrication involves techniques such as laser cutting, CNC machining, and thermoforming, enabling precise shaping and smooth edges with minimal post-processing. Polycarbonate fabrication requires more robust methods like hot bending, cold bending, and high-pressure molding due to its higher impact resistance and flexibility. Both materials use fabrication methods suited to their physical properties, with acrylic excelling in clarity and ease of machining, while polycarbonate offers superior strength and durability.

Workability and Machining Differences

Acrylic fabrication offers superior clarity and surface finish with easier cutting, drilling, and bonding due to its lower melting point and machining temperature compared to polycarbonate. Polycarbonate fabrication excels in impact resistance and toughness but requires specialized tools and slower machining speeds to prevent melting and cracking. Workability differences mean acrylic is preferred for intricate designs and optical-quality projects, while polycarbonate suits applications demanding higher durability and impact strength.

Cost Analysis: Acrylic vs Polycarbonate

Acrylic fabrication generally offers a lower cost compared to polycarbonate, with raw material prices averaging around $2 to $4 per pound, whereas polycarbonate typically ranges from $3 to $6 per pound. Acrylic also requires less specialized equipment and processing time, reducing overall labor and production expenses. Despite higher upfront costs, polycarbonate's superior impact resistance and durability may justify the investment for applications demanding enhanced toughness.

Applications in Various Industries

Acrylic fabrication excels in applications requiring high clarity and UV resistance, making it ideal for signage, display cases, and protective barriers in retail and advertising industries. Polycarbonate fabrication offers superior impact resistance and heat tolerance, preferred in automotive components, safety equipment, and electronic housings where durability is critical. Both materials are extensively used in construction and medical industries, but acrylic is favored for aesthetic appeal while polycarbonate is selected for strength and safety.

Environmental Impact and Recyclability

Acrylic fabrication typically results in lower environmental impact due to its lesser energy requirements and ability to be recycled through chemical processes, whereas polycarbonate fabrication consumes more energy and emits higher levels of greenhouse gases. Acrylic materials offer higher recyclability with established recycling streams, while polycarbonate recycling is more complex and less widespread, often leading to landfill disposal. Choosing acrylic over polycarbonate enhances sustainability through reduced carbon footprint and better end-of-life material recovery.

Choosing the Right Material for Your Project

Acrylic fabrication offers excellent clarity, UV resistance, and ease of cutting, making it ideal for applications requiring lightweight, weather-resistant, and aesthetically pleasing materials. Polycarbonate fabrication provides superior impact resistance and higher temperature tolerance, suitable for projects demanding durability and strength under extreme conditions. Selecting the right material depends on the specific requirements of your project, balancing factors such as optical clarity, mechanical strength, and environmental exposure.

Acrylic Fabrication vs Polycarbonate Fabrication Infographic

materialdif.com

materialdif.com