Acrylic panel bonding provides a seamless, clear finish that maintains the material's aesthetic integrity and ensures even stress distribution, reducing the risk of cracks and leaks. Mechanical fastening involves screws or bolts that can create stress points, potential damage, and visible hardware, which may detract from the acrylic's smooth appearance. Choosing bonding over mechanical fastening enhances durability and preserves the visual appeal in applications requiring strong, transparent joins.

Table of Comparison

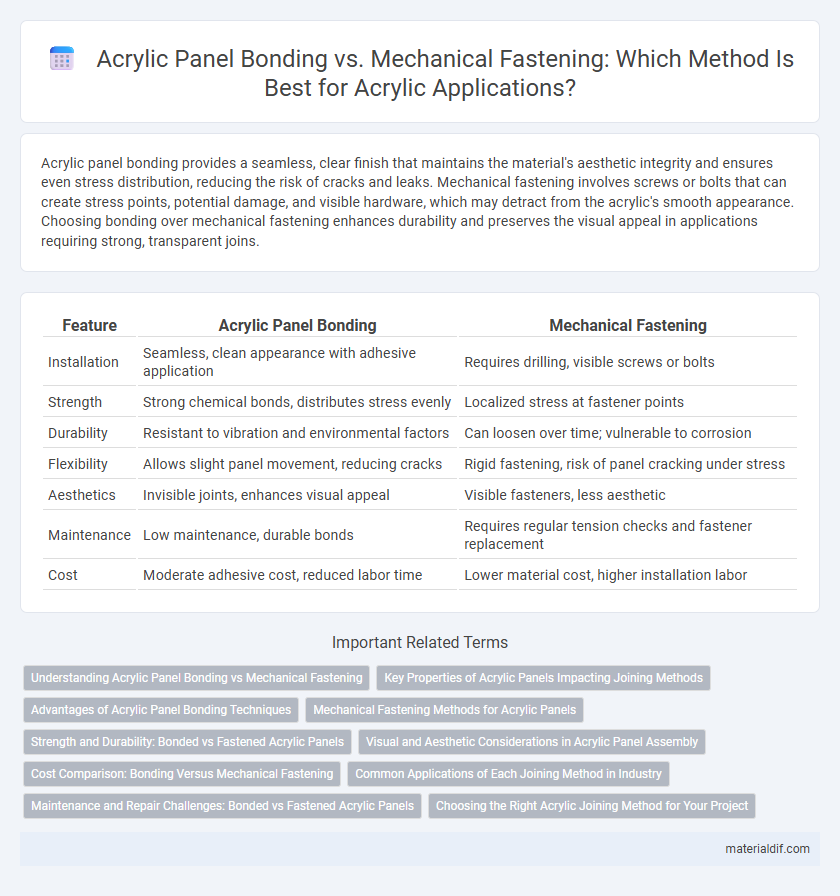

| Feature | Acrylic Panel Bonding | Mechanical Fastening |

|---|---|---|

| Installation | Seamless, clean appearance with adhesive application | Requires drilling, visible screws or bolts |

| Strength | Strong chemical bonds, distributes stress evenly | Localized stress at fastener points |

| Durability | Resistant to vibration and environmental factors | Can loosen over time; vulnerable to corrosion |

| Flexibility | Allows slight panel movement, reducing cracks | Rigid fastening, risk of panel cracking under stress |

| Aesthetics | Invisible joints, enhances visual appeal | Visible fasteners, less aesthetic |

| Maintenance | Low maintenance, durable bonds | Requires regular tension checks and fastener replacement |

| Cost | Moderate adhesive cost, reduced labor time | Lower material cost, higher installation labor |

Understanding Acrylic Panel Bonding vs Mechanical Fastening

Acrylic panel bonding uses specialized adhesives such as solvent-based cements or UV-curing glues to create seamless, strong joints that preserve the panel's optical clarity and structural integrity. Mechanical fastening relies on screws, bolts, or rivets, which can introduce stress points and potential cracks in acrylic panels, compromising aesthetics and durability. Understanding the differences in load distribution, environmental resistance, and long-term performance helps determine the best method for applications requiring transparency and strength.

Key Properties of Acrylic Panels Impacting Joining Methods

Acrylic panels exhibit high clarity, excellent weather resistance, and inherent rigidity, making adhesive bonding a preferred method for smooth, transparent joins without visible fasteners. Their low surface energy requires specialized primers or solvent-based adhesives for optimal bond strength, enhancing durability in applications exposed to moisture and UV light. Mechanical fastening, while providing immediate structural support, may cause stress concentrations or surface damage, compromising the panel's optical clarity and impact resistance over time.

Advantages of Acrylic Panel Bonding Techniques

Acrylic panel bonding techniques offer superior strength and a seamless, aesthetically pleasing finish compared to mechanical fastening methods. These bonding methods distribute stress evenly across the joint, reducing the risk of cracking or weakening under pressure. Bonded acrylic panels also provide improved resistance to moisture and environmental factors, enhancing durability and longevity in various applications.

Mechanical Fastening Methods for Acrylic Panels

Mechanical fastening methods for acrylic panels include screws, bolts, and rivets, offering strong, durable connections without the need for adhesives. These fasteners provide easy assembly and disassembly, allowing for adjustments or replacements while maintaining structural integrity. Proper selection of fastener type and size is crucial to prevent cracking or stress on acrylic panels during installation and use.

Strength and Durability: Bonded vs Fastened Acrylic Panels

Acrylic panel bonding offers superior strength by creating a continuous, stress-distributing joint that minimizes cracks and leaks compared to mechanical fastening, which relies on localized pressure points prone to stress concentration and potential failure. Bonded acrylic panels demonstrate enhanced durability as the adhesive layer absorbs vibrations and environmental stressors, extending the lifespan of the assembly beyond that of fastened joints subject to loosening or corrosion. In applications demanding long-term integrity and resistance to mechanical fatigue, bonded acrylic panels outperform fastened counterparts in maintaining structural stability and sealing effectiveness.

Visual and Aesthetic Considerations in Acrylic Panel Assembly

Acrylic panel bonding offers seamless joints with crystal-clear clarity, maintaining the panel's smooth, glossy surface without visible hardware, which enhances the overall aesthetic appeal. Mechanical fastening often results in visible screws or rivets, disrupting the visual uniformity and potentially causing stress points that detract from the sleek, polished look of acrylic assemblies. Opting for solvent or UV-curing adhesives ensures a cleaner finish and preserves the high transparency and light transmission characteristics inherent to acrylic panels.

Cost Comparison: Bonding Versus Mechanical Fastening

Acrylic panel bonding typically incurs lower overall costs compared to mechanical fastening due to reduced labor time and fewer materials such as screws or brackets. Bonding methods offer enhanced aesthetic appeal by eliminating visible hardware, which can decrease post-installation finishing expenses. Mechanical fastening may increase long-term maintenance costs owing to potential loosening and damage around fastener points.

Common Applications of Each Joining Method in Industry

Acrylic panel bonding is extensively utilized in industries such as automotive, signage, and electronics for applications requiring seamless, transparent joins that maintain aesthetic appeal and structural integrity. Mechanical fastening is preferred in construction, aerospace, and heavy machinery sectors where strength, disassembly, and vibration resistance are critical. Both methods address specific industrial needs, with bonding favored for visual clarity and fastening chosen for mechanical reliability.

Maintenance and Repair Challenges: Bonded vs Fastened Acrylic Panels

Bonded acrylic panels offer seamless joints with minimal visual disruption but pose significant challenges during maintenance, as adhesives can degrade or weaken, making panel separation difficult and increasing repair time. Mechanical fastening allows easier disassembly and localized repairs, reducing downtime and preserving panel integrity, yet it may cause stress points or aesthetic issues due to visible fasteners. Selecting the optimal method requires balancing the ease of repair against the desired appearance and long-term durability of acrylic panel installations.

Choosing the Right Acrylic Joining Method for Your Project

Selecting the appropriate acrylic joining method depends on factors such as load requirements, transparency needs, and environmental conditions. Acrylic panel bonding offers a seamless, clear, and aesthetically pleasing joint ideal for light to moderate loads, while mechanical fastening provides superior strength for heavy-duty applications but may compromise visual clarity. Understanding the project's structural demands and design priorities ensures optimal performance and durability of acrylic assemblies.

Acrylic Panel Bonding vs Mechanical Fastening Infographic

materialdif.com

materialdif.com