Acrylic fabrication offers greater design flexibility and is ideal for custom, small-batch, or artistic applications due to its ease of cutting, bending, and bonding. Injection molding suits high-volume production with consistent quality, providing intricate shapes and fast turnaround but requires expensive molds and longer initial setup time. Choosing between acrylic fabrication and injection molding depends on production volume, cost considerations, and desired design complexity.

Table of Comparison

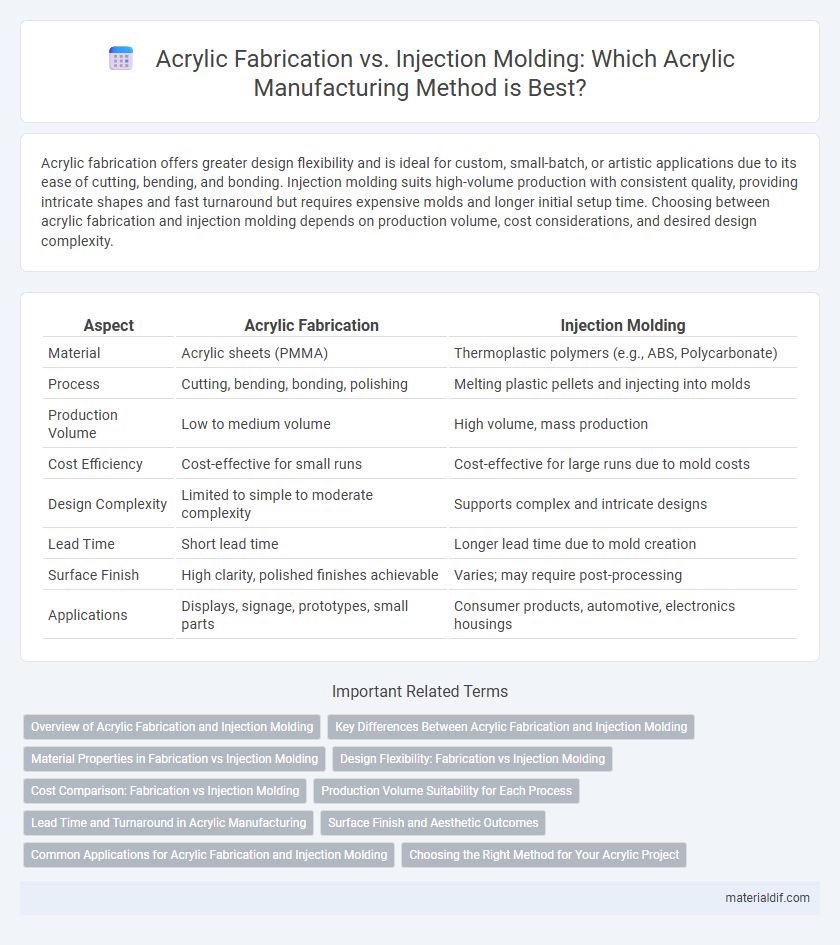

| Aspect | Acrylic Fabrication | Injection Molding |

|---|---|---|

| Material | Acrylic sheets (PMMA) | Thermoplastic polymers (e.g., ABS, Polycarbonate) |

| Process | Cutting, bending, bonding, polishing | Melting plastic pellets and injecting into molds |

| Production Volume | Low to medium volume | High volume, mass production |

| Cost Efficiency | Cost-effective for small runs | Cost-effective for large runs due to mold costs |

| Design Complexity | Limited to simple to moderate complexity | Supports complex and intricate designs |

| Lead Time | Short lead time | Longer lead time due to mold creation |

| Surface Finish | High clarity, polished finishes achievable | Varies; may require post-processing |

| Applications | Displays, signage, prototypes, small parts | Consumer products, automotive, electronics housings |

Overview of Acrylic Fabrication and Injection Molding

Acrylic fabrication involves cutting, bending, and assembling acrylic sheets using techniques such as laser cutting, thermoforming, and adhesive bonding to create custom shapes and designs. Injection molding of acrylic uses heated acrylic pellets injected into molds under high pressure to produce detailed, complex parts with high production efficiency. Fabrication suits low to medium volume, large or flat parts, while injection molding excels in high-volume production of intricate, durable components.

Key Differences Between Acrylic Fabrication and Injection Molding

Acrylic fabrication involves processes like cutting, bending, and polishing sheets of acrylic to create custom shapes, offering high design flexibility and smooth finishes ideal for signage and displays. Injection molding uses high-pressure machines to inject molten acrylic into molds, allowing mass production of complex parts with consistent dimensions and reduced labor costs. Key differences include scalability, with injection molding suited for large volumes and acrylic fabrication better for bespoke or limited-run projects, as well as variations in tooling costs and surface finish quality.

Material Properties in Fabrication vs Injection Molding

Acrylic fabrication involves processes such as cutting, bonding, and thermoforming, which preserve the material's optical clarity, impact resistance, and weatherability, making it ideal for applications requiring transparency and durability. Injection molding of acrylic allows for complex shapes and high-volume production but may alter the polymer's inherent mechanical properties, potentially reducing impact strength and causing internal stresses. The choice between fabrication and injection molding depends on balancing the desired surface finish, optical quality, and mechanical performance tailored to specific application requirements.

Design Flexibility: Fabrication vs Injection Molding

Acrylic fabrication offers superior design flexibility by allowing custom shapes, sizes, and detailed modifications through cutting, bending, and assembling processes. Injection molding requires upfront investment in molds but enables consistent production of complex, high-precision parts with limited post-processing. Fabrication suits low to medium-volume, unique designs, while injection molding excels in mass production with intricate geometries.

Cost Comparison: Fabrication vs Injection Molding

Acrylic fabrication typically incurs higher per-unit costs due to manual processes and longer production times, making it ideal for low-volume or custom projects. Injection molding requires significant upfront investment in molds but achieves lower costs at high volumes through automation and faster cycle times. For mass production, injection molding offers greater cost efficiency, while acrylic fabrication remains cost-effective for prototypes and small batch runs.

Production Volume Suitability for Each Process

Acrylic fabrication is ideal for low to medium production volumes due to its cost-effective tooling and flexibility in custom designs. Injection molding suits high production volumes, offering rapid manufacturing and consistent part quality despite higher initial mold creation costs. Selecting between these processes depends heavily on required quantities and budget constraints.

Lead Time and Turnaround in Acrylic Manufacturing

Acrylic fabrication typically offers faster lead times compared to injection molding due to its simpler production process and minimal tooling requirements. Turnaround in acrylic manufacturing is often measured in days versus weeks for injection molding, making it ideal for rapid prototyping and small to medium production runs. Injection molding suits high-volume orders but involves longer setup and curing times, impacting overall project speed.

Surface Finish and Aesthetic Outcomes

Acrylic fabrication offers superior surface finish and aesthetic outcomes compared to injection molding due to its ability to achieve crystal-clear transparency and smooth edges through polishing and CNC machining. Injection molding, while efficient for mass production, often results in minor surface imperfections such as flow lines and ejector marks that require secondary finishing processes to match acrylic's clarity. Consequently, acrylic fabrication remains the preferred method for applications demanding high visual quality and flawless appearance.

Common Applications for Acrylic Fabrication and Injection Molding

Acrylic fabrication is commonly used in applications such as custom signage, display cases, and protective barriers due to its excellent optical clarity and ease of machining. Injection molding of acrylic is preferred for mass production of small, precise components like lenses, light diffusers, and electronic device housings, offering high repeatability and complex geometries. Both methods serve different industries with acrylic fabrication suited for bespoke projects and injection molding ideal for high-volume manufacturing.

Choosing the Right Method for Your Acrylic Project

Acrylic fabrication offers greater design flexibility and is ideal for custom or small-batch projects, allowing precise cutting, bending, and polishing of sheets. Injection molding suits high-volume production, providing consistent, complex shapes with faster turnaround times but requires expensive molds and setup. Selecting the right method depends on project scale, design complexity, budget, and desired finish quality.

Acrylic Fabrication vs Injection Molding Infographic

materialdif.com

materialdif.com