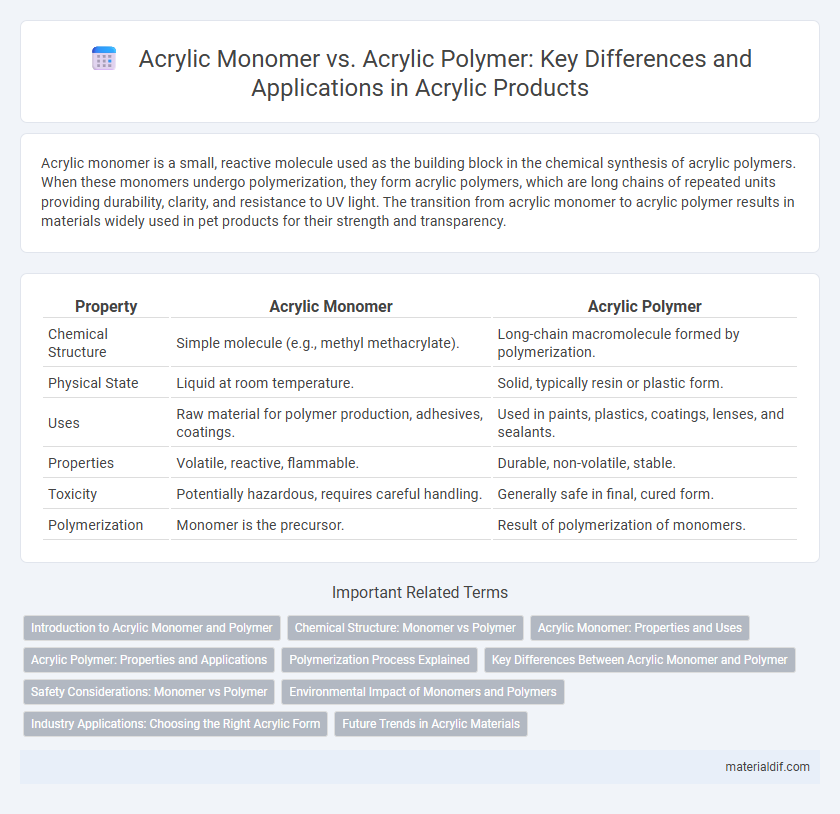

Acrylic monomer is a small, reactive molecule used as the building block in the chemical synthesis of acrylic polymers. When these monomers undergo polymerization, they form acrylic polymers, which are long chains of repeated units providing durability, clarity, and resistance to UV light. The transition from acrylic monomer to acrylic polymer results in materials widely used in pet products for their strength and transparency.

Table of Comparison

| Property | Acrylic Monomer | Acrylic Polymer |

|---|---|---|

| Chemical Structure | Simple molecule (e.g., methyl methacrylate). | Long-chain macromolecule formed by polymerization. |

| Physical State | Liquid at room temperature. | Solid, typically resin or plastic form. |

| Uses | Raw material for polymer production, adhesives, coatings. | Used in paints, plastics, coatings, lenses, and sealants. |

| Properties | Volatile, reactive, flammable. | Durable, non-volatile, stable. |

| Toxicity | Potentially hazardous, requires careful handling. | Generally safe in final, cured form. |

| Polymerization | Monomer is the precursor. | Result of polymerization of monomers. |

Introduction to Acrylic Monomer and Polymer

Acrylic monomers, such as methyl methacrylate (MMA), are the fundamental building blocks used in the production of acrylic polymers through polymerization processes. Acrylic polymers exhibit enhanced durability, flexibility, and resistance to UV radiation and weathering compared to their monomer counterparts. Understanding the transformation from acrylic monomer to polymer is essential for applications in coatings, adhesives, and plastics manufacturing.

Chemical Structure: Monomer vs Polymer

Acrylic monomers, such as methyl methacrylate, consist of small, single molecules with reactive vinyl groups enabling polymerization. Acrylic polymers are large macromolecules formed by the repeated covalent bonding of monomer units, resulting in long chains with distinct physical properties. The chemical structure transformation from monomer to polymer involves breaking double bonds and creating a stable, high molecular weight polymer network.

Acrylic Monomer: Properties and Uses

Acrylic monomers, such as methyl methacrylate (MMA), are clear, colorless liquids with low viscosity and high reactivity, enabling rapid polymerization under controlled conditions. These monomers serve as essential building blocks for producing acrylic polymers used in coatings, adhesives, and medical devices due to their excellent optical clarity and weather resistance. Their chemical structure allows customization in mechanical properties, making them versatile for various industrial applications requiring durability and transparency.

Acrylic Polymer: Properties and Applications

Acrylic polymers exhibit excellent optical clarity, weather resistance, and chemical stability, making them ideal for applications in coatings, adhesives, and transparent barriers. Their high tensile strength and flexibility enable use in automotive parts, medical devices, and signage. Furthermore, acrylic polymers are widely favored in construction and electronics due to their durability and ease of fabrication.

Polymerization Process Explained

Acrylic monomers, primarily methyl methacrylate (MMA), undergo polymerization through free radical or controlled radical mechanisms to form acrylic polymers with enhanced mechanical and optical properties. The polymerization process involves initiation by a catalyst or initiator, propagation where monomers link into long chains, and termination to stop chain growth, resulting in a high molecular weight polymer. Acrylic polymers exhibit improved durability, clarity, and flexibility compared to monomers, making them essential in applications like paints, adhesives, and acrylic glass production.

Key Differences Between Acrylic Monomer and Polymer

Acrylic monomer, primarily methyl methacrylate (MMA), is a volatile, reactive compound used as the building block for acrylic polymers through polymerization processes. Acrylic polymer, formed by linking numerous monomer units, exhibits enhanced properties like durability, flexibility, and chemical resistance, making it suitable for applications in coatings, adhesives, and plastics. The key difference lies in the monomer's liquid, reactive state versus the polymer's solid, stable macromolecular structure with distinct physical and chemical characteristics.

Safety Considerations: Monomer vs Polymer

Acrylic monomers, such as methyl methacrylate, pose higher safety risks due to their flammability, volatility, and potential skin and respiratory irritation. In contrast, acrylic polymers are generally safer, being non-volatile and chemically stable, reducing exposure hazards during handling and use. Proper ventilation and protective equipment are crucial when working with monomers to minimize health risks, while polymers demand standard safety precautions.

Environmental Impact of Monomers and Polymers

Acrylic monomers, such as methyl methacrylate, exhibit higher volatility and toxicity, contributing to air pollution and potential health hazards during manufacturing and application. In contrast, acrylic polymers are generally more stable, less volatile, and inert, reducing environmental risks through decreased emissions and enhanced recyclability. The environmental impact of acrylic polymers is significantly lower compared to monomers, primarily due to reduced leaching, lower toxicity, and better end-of-life management options like recycling and safe disposal.

Industry Applications: Choosing the Right Acrylic Form

Acrylic monomers, such as methyl methacrylate, serve as the building blocks for producing acrylic polymers through polymerization processes, making monomers essential in custom formulations for industrial coatings, adhesives, and sealants. Acrylic polymers are preferred in applications requiring durable, UV-resistant finishes, including automotive paints, construction materials, and optical lenses, due to their excellent clarity and weatherability. Selecting the right acrylic form depends on application-specific requirements like flexibility, hardness, and chemical resistance to optimize performance and manufacturing efficiency.

Future Trends in Acrylic Materials

Acrylic monomers, such as methyl methacrylate, serve as the foundational building blocks for synthesizing advanced acrylic polymers used in diverse applications like coatings, adhesives, and medical devices. Future trends emphasize the development of sustainable and bio-based acrylic monomers to enhance polymer performance while reducing environmental impact. Innovations in polymerization techniques and nanocomposite integration are driving new acrylic polymers with improved durability, flexibility, and functional properties for cutting-edge industrial and consumer products.

Acrylic Monomer vs Acrylic Polymer Infographic

materialdif.com

materialdif.com