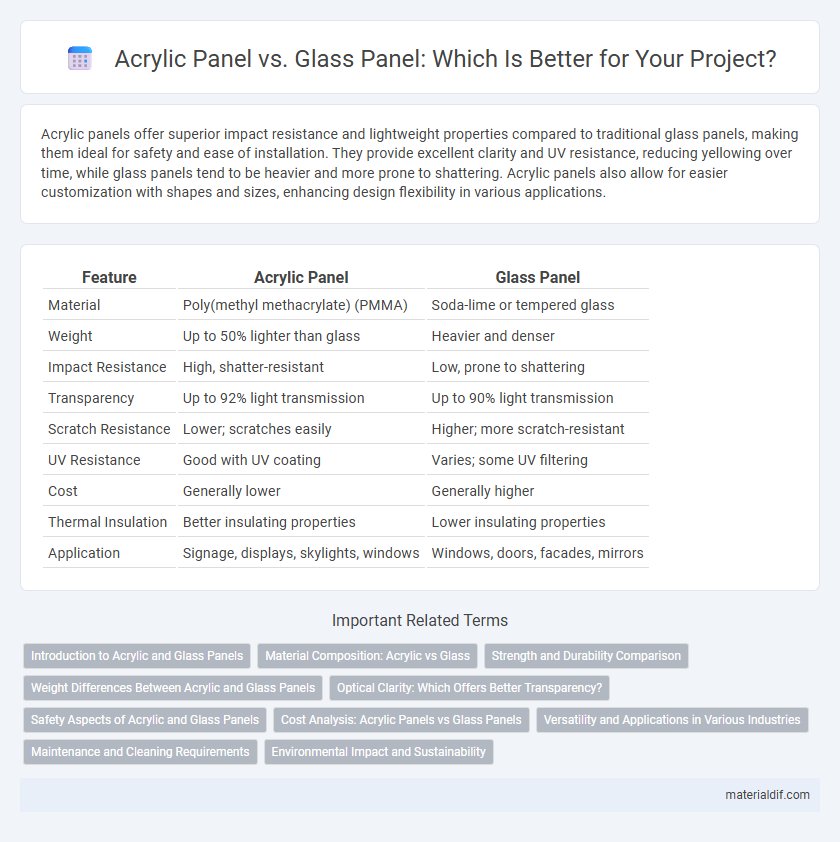

Acrylic panels offer superior impact resistance and lightweight properties compared to traditional glass panels, making them ideal for safety and ease of installation. They provide excellent clarity and UV resistance, reducing yellowing over time, while glass panels tend to be heavier and more prone to shattering. Acrylic panels also allow for easier customization with shapes and sizes, enhancing design flexibility in various applications.

Table of Comparison

| Feature | Acrylic Panel | Glass Panel |

|---|---|---|

| Material | Poly(methyl methacrylate) (PMMA) | Soda-lime or tempered glass |

| Weight | Up to 50% lighter than glass | Heavier and denser |

| Impact Resistance | High, shatter-resistant | Low, prone to shattering |

| Transparency | Up to 92% light transmission | Up to 90% light transmission |

| Scratch Resistance | Lower; scratches easily | Higher; more scratch-resistant |

| UV Resistance | Good with UV coating | Varies; some UV filtering |

| Cost | Generally lower | Generally higher |

| Thermal Insulation | Better insulating properties | Lower insulating properties |

| Application | Signage, displays, skylights, windows | Windows, doors, facades, mirrors |

Introduction to Acrylic and Glass Panels

Acrylic panels, crafted from polymethyl methacrylate (PMMA), offer lightweight and shatter-resistant alternatives to traditional glass panels, ensuring enhanced safety in various applications. Glass panels, composed mainly of silica, provide superior scratch resistance and clarity, making them ideal for aesthetic and structural uses. Both materials serve distinct purposes, with acrylic excelling in impact durability and glass in hardness and optical clarity.

Material Composition: Acrylic vs Glass

Acrylic panels are made from polymethyl methacrylate (PMMA), a lightweight thermoplastic resin known for its impact resistance and clarity, whereas glass panels consist primarily of silica and various metal oxides, providing a hard, brittle surface with high scratch resistance. Acrylic's molecular structure allows for better flexibility and shatter resistance compared to the rigid, crystalline lattice of glass, making acrylic panels more suitable for applications requiring durability and safety. While glass panels offer superior hardness and heat resistance due to their inorganic composition, acrylic panels excel in lightweight construction and ease of fabrication.

Strength and Durability Comparison

Acrylic panels offer significantly higher impact resistance than glass panels, making them less prone to shattering under stress. Their durability extends to better resistance against scratches and weather-related wear, ensuring longer-lasting clarity and performance in various environments. Acrylic's lightweight nature enhances structural strength without compromising toughness compared to traditional glass panels.

Weight Differences Between Acrylic and Glass Panels

Acrylic panels weigh approximately 50% less than glass panels of the same size and thickness, making them easier to handle and install. This significant weight difference reduces transportation costs and enhances safety in applications such as windows, displays, and protective barriers. The lighter profile of acrylic panels also minimizes structural support requirements compared to heavier glass panels.

Optical Clarity: Which Offers Better Transparency?

Acrylic panels provide superior optical clarity compared to glass panels due to their higher light transmittance, typically around 92%, whereas standard glass transmits about 88-90%. Acrylic's clarity is enhanced by its lower refractive index and reduced internal reflection, resulting in less distortion and better visual sharpness. For applications demanding maximum transparency and minimal color distortion, acrylic panels are the preferred choice over conventional glass.

Safety Aspects of Acrylic and Glass Panels

Acrylic panels offer superior safety compared to glass panels due to their high impact resistance and shatterproof properties, significantly reducing the risk of injury from breakage. While glass panels can shatter into sharp, dangerous shards, acrylic panels crack in a safer manner, maintaining structural integrity and preventing hazardous fragments. This makes acrylic panels ideal for environments where safety is a priority, such as schools, hospitals, and playgrounds.

Cost Analysis: Acrylic Panels vs Glass Panels

Acrylic panels typically cost 50-70% less than glass panels, making them a budget-friendly option for large-scale projects. Their lightweight nature reduces shipping and installation expenses compared to the heavier and more fragile glass panels. Maintenance costs for acrylic are generally lower due to its shatter-resistant properties, minimizing replacement frequency over time.

Versatility and Applications in Various Industries

Acrylic panels offer superior versatility compared to glass panels, making them ideal for diverse applications across industries such as automotive, retail, and construction. Their lightweight, impact-resistant properties enable custom fabrication for signage, protective barriers, and display cases, outperforming traditional glass in durability and ease of installation. Acrylic's adaptability allows for enhanced optical clarity and UV resistance, meeting specific requirements in healthcare, aerospace, and interior design sectors.

Maintenance and Cleaning Requirements

Acrylic panels require less maintenance than glass panels due to their resistance to shattering and lighter weight, reducing the risk of damage during cleaning. Cleaning acrylic involves using mild soap and water or specialized plastic cleaners, avoiding abrasive materials that can cause scratches. Glass panels can be cleaned with standard glass cleaners but may need more frequent maintenance to prevent streaks and breakage.

Environmental Impact and Sustainability

Acrylic panels have a lower carbon footprint compared to glass panels due to their lighter weight and energy-efficient manufacturing process, resulting in reduced transportation emissions and resource consumption. Acrylic is also recyclable and has a longer lifespan with higher impact resistance, reducing the need for frequent replacements and minimizing landfill waste. Glass panels, while durable and recyclable, require higher energy inputs during production and transportation, contributing to greater environmental impact overall.

Acrylic Panel vs Glass Panel Infographic

materialdif.com

materialdif.com