Acrylic displays offer superior clarity and scratch resistance compared to polycarbonate displays, making them ideal for showcasing products with sharp, vibrant visuals. Polycarbonate displays, however, provide greater impact resistance and durability, which is beneficial in high-traffic or outdoor environments. Choosing between acrylic and polycarbonate displays depends on the need for optical clarity versus toughness in your specific acrylic pet display application.

Table of Comparison

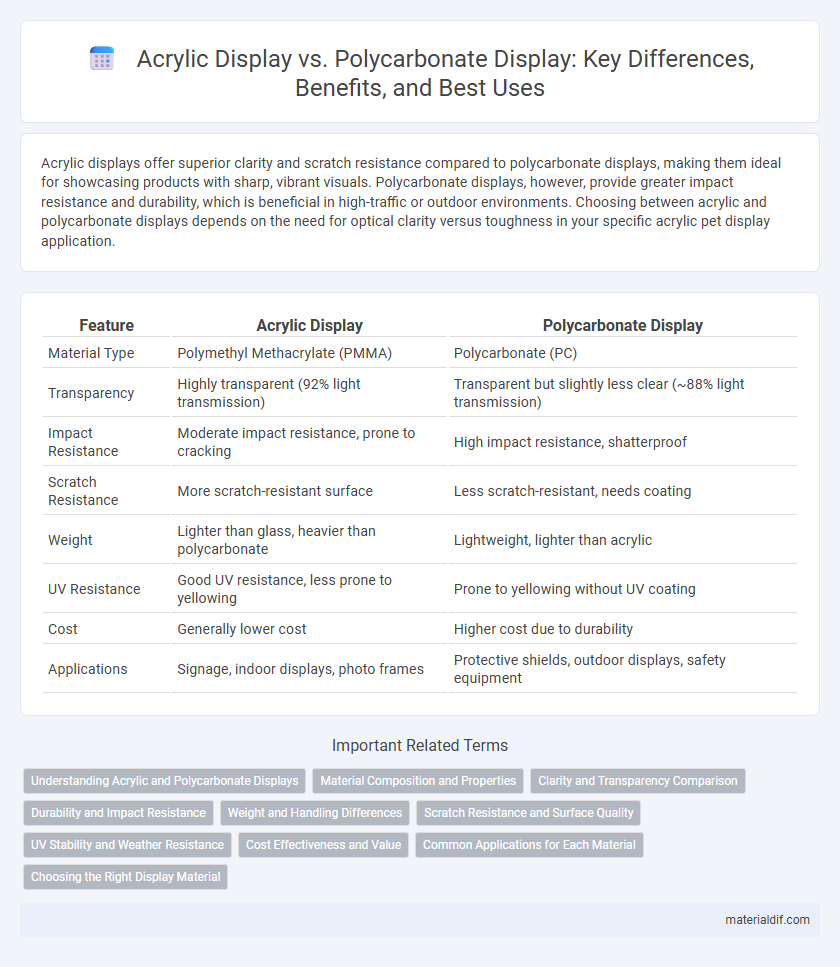

| Feature | Acrylic Display | Polycarbonate Display |

|---|---|---|

| Material Type | Polymethyl Methacrylate (PMMA) | Polycarbonate (PC) |

| Transparency | Highly transparent (92% light transmission) | Transparent but slightly less clear (~88% light transmission) |

| Impact Resistance | Moderate impact resistance, prone to cracking | High impact resistance, shatterproof |

| Scratch Resistance | More scratch-resistant surface | Less scratch-resistant, needs coating |

| Weight | Lighter than glass, heavier than polycarbonate | Lightweight, lighter than acrylic |

| UV Resistance | Good UV resistance, less prone to yellowing | Prone to yellowing without UV coating |

| Cost | Generally lower cost | Higher cost due to durability |

| Applications | Signage, indoor displays, photo frames | Protective shields, outdoor displays, safety equipment |

Understanding Acrylic and Polycarbonate Displays

Acrylic displays offer superior clarity and UV resistance, making them ideal for showcasing products with vibrant colors and sharp details. Polycarbonate displays provide greater impact resistance and durability, suitable for high-traffic environments where strength and safety are priorities. Understanding the material properties helps in choosing acrylic for elegant presentation or polycarbonate for robust, long-lasting use.

Material Composition and Properties

Acrylic displays are composed of polymethyl methacrylate (PMMA), known for its clarity, UV resistance, and scratch resistance, making them ideal for vibrant visual presentations. Polycarbonate displays, made from polycarbonate resin, offer superior impact resistance and greater durability but tend to yellow over time under UV exposure. The choice between acrylic and polycarbonate depends on the balance between optical clarity and toughness required for specific display applications.

Clarity and Transparency Comparison

Acrylic displays offer superior clarity and transparency compared to polycarbonate, with light transmittance rates around 92%, making them ideal for showcasing vibrant visuals. Polycarbonate displays, while more impact-resistant, typically have lower optical purity and can appear slightly hazier due to their molecular structure. The enhanced clarity of acrylic ensures sharper, more vivid presentations in retail, museum, and signage applications.

Durability and Impact Resistance

Acrylic displays offer excellent clarity and scratch resistance but are less impact-resistant and more prone to cracking under heavy stress compared to polycarbonate displays. Polycarbonate displays provide superior durability and impact resistance, making them ideal for high-impact environments and reducing the risk of breakage. The choice between acrylic and polycarbonate displays depends on the balance needed between optical clarity and toughness for specific application needs.

Weight and Handling Differences

Acrylic displays are significantly lighter than polycarbonate displays, making them easier to handle and install, especially in large formats. While acrylic offers a rigid and scratch-resistant surface, polycarbonate is more impact-resistant but heavier, which can lead to increased fatigue during installation and transportation. The lighter weight of acrylic makes it a preferred choice for applications where ease of handling and cost-effective shipping are priorities.

Scratch Resistance and Surface Quality

Acrylic displays offer superior surface clarity and scratch resistance compared to polycarbonate, making them ideal for environments requiring high visual aesthetics and durability. While polycarbonate is more impact-resistant, its surface is more prone to scratching, necessitating frequent maintenance or protective coatings. Acrylic's hard surface resists everyday abrasions better, ensuring long-lasting visual quality and minimal surface imperfections.

UV Stability and Weather Resistance

Acrylic displays offer superior UV stability compared to polycarbonate, maintaining clarity and preventing yellowing over prolonged sun exposure. Weather resistance in acrylic ensures durability without significant degradation in outdoor environments, making it ideal for long-term outdoor signage. Polycarbonate displays, while impact-resistant, tend to degrade faster under UV radiation, leading to discoloration and reduced lifespan.

Cost Effectiveness and Value

Acrylic displays offer superior cost-effectiveness compared to polycarbonate displays due to lower material and manufacturing expenses while maintaining excellent optical clarity and scratch resistance. Polycarbonate displays provide higher impact resistance and durability, but their increased cost can limit value for budget-sensitive applications. Choosing acrylic balances affordability and visual appeal, making it ideal for retail signage and exhibition displays.

Common Applications for Each Material

Acrylic displays are commonly used in retail signage, point-of-purchase stands, and picture frames due to their clarity, lightweight nature, and ease of fabrication. Polycarbonate displays are preferred for safety shields, machine guards, and outdoor signage because of their superior impact resistance and UV stability. Both materials serve distinct applications based on durability and environmental exposure requirements.

Choosing the Right Display Material

Acrylic displays offer superior clarity and scratch resistance, making them ideal for retail environments where visual appeal is paramount. Polycarbonate displays provide enhanced impact resistance and durability, suitable for high-traffic or outdoor settings requiring toughness. Choosing the right display material depends on balancing clarity preferences and durability needs to optimize the display's performance and longevity.

Acrylic Display vs Polycarbonate Display Infographic

materialdif.com

materialdif.com