Cell cast acrylic offers superior optical clarity and greater chemical resistance due to its manufacturing process, making it ideal for high-quality applications such as displays and lenses. Continuous cast acrylic is produced in larger sheets with consistent thickness, providing cost-effective solutions for general-purpose uses where slight variations are acceptable. Choosing between cell cast and continuous cast acrylic depends on the specific requirements for clarity, strength, and budget in your project.

Table of Comparison

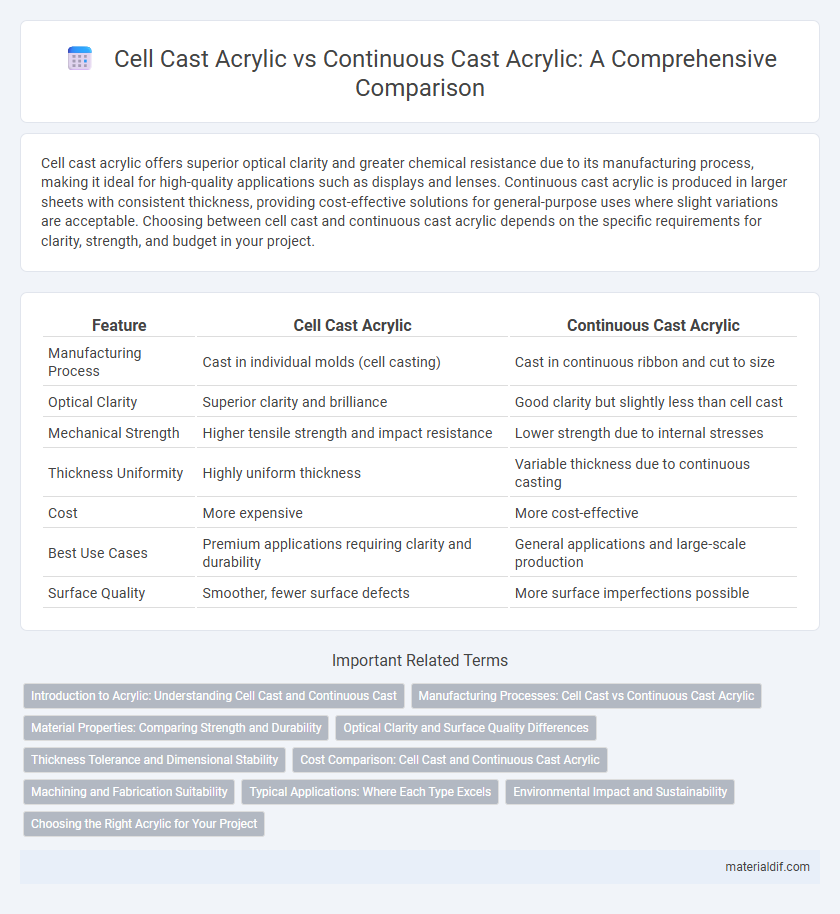

| Feature | Cell Cast Acrylic | Continuous Cast Acrylic |

|---|---|---|

| Manufacturing Process | Cast in individual molds (cell casting) | Cast in continuous ribbon and cut to size |

| Optical Clarity | Superior clarity and brilliance | Good clarity but slightly less than cell cast |

| Mechanical Strength | Higher tensile strength and impact resistance | Lower strength due to internal stresses |

| Thickness Uniformity | Highly uniform thickness | Variable thickness due to continuous casting |

| Cost | More expensive | More cost-effective |

| Best Use Cases | Premium applications requiring clarity and durability | General applications and large-scale production |

| Surface Quality | Smoother, fewer surface defects | More surface imperfections possible |

Introduction to Acrylic: Understanding Cell Cast and Continuous Cast

Cell cast acrylic is produced by pouring liquid MMA monomer into molds, creating sheets with superior optical clarity, high rigidity, and excellent chemical resistance, ideal for high-end applications. Continuous cast acrylic involves casting liquid monomer onto a moving casting belt, resulting in consistent thickness and surface quality, making it suitable for large-scale industrial uses. Understanding these manufacturing processes helps in selecting the right acrylic type based on performance requirements and cost-effectiveness.

Manufacturing Processes: Cell Cast vs Continuous Cast Acrylic

Cell cast acrylic is produced by pouring liquid monomer into individual molds, creating thick, high-purity sheets known for superior optical clarity and strength. Continuous cast acrylic is manufactured by spreading liquid monomer between moving polished rollers, resulting in thinner, uniform sheets ideal for large-scale applications but with slightly lower mechanical properties. The cell casting process allows greater control over thickness and structural integrity, while continuous casting offers efficiency and speed in volume production.

Material Properties: Comparing Strength and Durability

Cell cast acrylic exhibits superior strength and durability due to its thicker, bubble-free structure, making it resistant to cracking and impact. Continuous cast acrylic, while more cost-effective, tends to have more internal stresses and less uniform thickness, which can compromise long-term durability. The choice between cell cast and continuous cast acrylic depends heavily on application-specific requirements for strength and resistance to environmental wear.

Optical Clarity and Surface Quality Differences

Cell Cast Acrylic offers superior optical clarity due to its slower curing process, resulting in fewer internal stresses and enhanced light transmission, making it ideal for applications requiring high transparency. Continuous Cast Acrylic, produced via a faster, continuous extrusion method, often exhibits slight variations in optical quality and surface finish, with minor impurities that can affect clarity. While both types maintain good surface quality, Cell Cast Acrylic typically provides a smoother, more uniform finish, beneficial for precision optical uses and premium display cases.

Thickness Tolerance and Dimensional Stability

Cell cast acrylic exhibits superior thickness tolerance, typically maintaining variations within +-0.005 inches, while continuous cast acrylic tends to have larger deviations around +-0.015 inches. The dimensional stability of cell cast acrylic is notably higher due to its slower, controlled curing process, reducing internal stresses and enhancing uniformity. Continuous cast acrylic, produced through a fast, continuous casting process, often shows increased warping and dimensional changes under thermal or mechanical stress.

Cost Comparison: Cell Cast and Continuous Cast Acrylic

Cell cast acrylic typically incurs higher production costs due to its manual pouring process and longer curing times, leading to a more expensive end product. Continuous cast acrylic is produced through an automated extrusion process, which reduces manufacturing expenses and results in a more cost-effective material. For applications prioritizing budget without compromising quality, continuous cast acrylic presents a more economical choice compared to the premium-priced cell cast acrylic.

Machining and Fabrication Suitability

Cell Cast Acrylic offers superior machinability and excellent optical clarity, making it ideal for precision fabrication tasks such as engraving, routing, and drilling. Continuous Cast Acrylic provides more uniform thickness and better consistency, which benefits large-scale sheet processing but may require more care during machining to avoid surface imperfections. Both types suit various fabrication methods, yet Cell Cast often results in higher-quality finishes for detailed projects.

Typical Applications: Where Each Type Excels

Cell cast acrylic is ideal for high-end displays, aquariums, and optical lenses due to its superior clarity and strength, making it perfect for applications demanding precision and durability. Continuous cast acrylic excels in large-scale manufacturing such as signage, automotive parts, and light fixtures, where cost efficiency and uniform thickness are critical. The choice between cell cast and continuous cast acrylic depends on the specific performance requirements and budget constraints of the project.

Environmental Impact and Sustainability

Cell cast acrylic exhibits a longer lifespan and greater resistance to discoloration, contributing to reduced material waste and lower environmental impact over time. Continuous cast acrylic production consumes less energy and generates fewer emissions, offering a more sustainable manufacturing process. Choosing between the two depends on balancing durability and eco-friendly production methods to minimize overall environmental footprint.

Choosing the Right Acrylic for Your Project

Cell Cast Acrylic offers superior optical clarity and higher impact resistance, making it ideal for projects requiring premium quality and durability, such as display cases and signage. Continuous Cast Acrylic provides more consistent thickness and is cost-effective for large-scale applications like glazing and light fixtures. Evaluating project needs for clarity, strength, and budget helps determine the best acrylic type, ensuring optimal performance and value.

Cell Cast Acrylic vs Continuous Cast Acrylic Infographic

materialdif.com

materialdif.com