Acrylic sheets and acrylic panels differ primarily in size and application, with sheets being thinner and used for lightweight projects like displays and protective barriers. Acrylic panels are thicker, offering enhanced durability and structural support, ideal for construction and heavy-duty installations. Choosing between the two depends on the specific requirements for strength, transparency, and flexibility in your project.

Table of Comparison

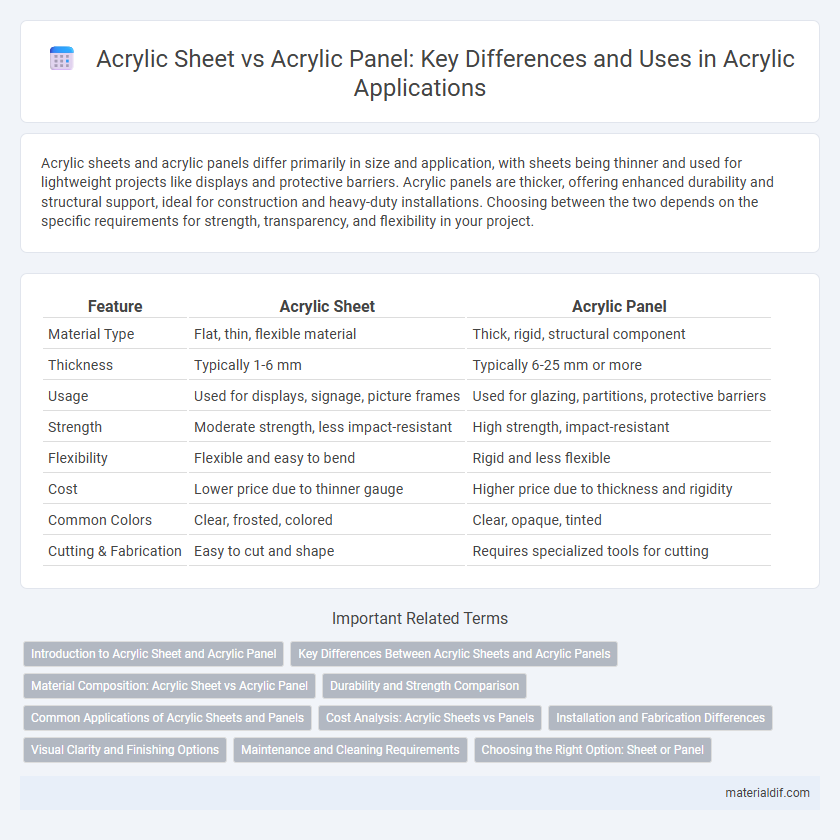

| Feature | Acrylic Sheet | Acrylic Panel |

|---|---|---|

| Material Type | Flat, thin, flexible material | Thick, rigid, structural component |

| Thickness | Typically 1-6 mm | Typically 6-25 mm or more |

| Usage | Used for displays, signage, picture frames | Used for glazing, partitions, protective barriers |

| Strength | Moderate strength, less impact-resistant | High strength, impact-resistant |

| Flexibility | Flexible and easy to bend | Rigid and less flexible |

| Cost | Lower price due to thinner gauge | Higher price due to thickness and rigidity |

| Common Colors | Clear, frosted, colored | Clear, opaque, tinted |

| Cutting & Fabrication | Easy to cut and shape | Requires specialized tools for cutting |

Introduction to Acrylic Sheet and Acrylic Panel

Acrylic sheets and acrylic panels are versatile materials made from polymethyl methacrylate (PMMA), known for their clarity, durability, and lightweight properties. Acrylic sheets are flat, thin, and commonly used in signage, displays, and protective barriers, while acrylic panels often refer to larger, thicker, or multi-layered configurations designed for architectural and industrial applications. Both offer excellent weather resistance and optical clarity, making them suitable for a wide range of indoor and outdoor uses.

Key Differences Between Acrylic Sheets and Acrylic Panels

Acrylic sheets are typically thinner, flexible, and used for lightweight applications such as picture frames and small displays, while acrylic panels are thicker, rigid, and designed for structural or protective purposes like glazing and partitions. Sheets often come in standard sizes and are easier to cut or shape, whereas panels offer enhanced durability and impact resistance for industrial or architectural usage. The key difference lies in their thickness, rigidity, and intended functionality, influencing selection based on project requirements.

Material Composition: Acrylic Sheet vs Acrylic Panel

Acrylic sheets and acrylic panels both consist primarily of polymethyl methacrylate (PMMA), known for its clarity, UV resistance, and lightweight properties. Acrylic sheets are typically produced as flat, uniform thickness materials ideal for glazing, displays, and protective barriers. Acrylic panels often refer to larger or multi-layered constructs used in architectural and industrial applications, sometimes integrating additives for enhanced strength or impact resistance while maintaining the base PMMA composition.

Durability and Strength Comparison

Acrylic sheets generally offer higher durability and greater impact resistance compared to acrylic panels, making them suitable for applications requiring robust performance. These sheets exhibit enhanced strength due to their thicker, solid composition, which withstands physical stress and environmental factors better than thinner, layered acrylic panels. Consequently, acrylic sheets are preferred for demanding uses such as protective barriers and outdoor signage where long-term durability is crucial.

Common Applications of Acrylic Sheets and Panels

Acrylic sheets are extensively used in signage, display cases, and protective barriers due to their clarity, lightweight nature, and ease of fabrication. Acrylic panels often serve architectural purposes such as skylights, partitions, and wall cladding, offering enhanced durability and weather resistance. Both options find applications in automotive components, aquariums, and furniture, where transparency and strength are essential.

Cost Analysis: Acrylic Sheets vs Panels

Acrylic sheets generally offer a lower initial cost compared to acrylic panels, making them a more budget-friendly option for projects requiring flat, uniform surfaces. Acrylic panels, often thicker and pre-fabricated with added features such as UV resistance or color treatments, carry a higher price due to manufacturing complexities and enhanced durability. Considering long-term value, acrylic panels may reduce replacement frequency and maintenance expenses despite their upfront premium.

Installation and Fabrication Differences

Acrylic sheets are typically flat and uniform, making them easier to cut, drill, and shape for custom installations, while acrylic panels often come pre-finished or framed, requiring less on-site fabrication but more precise fitting during installation. Installation of acrylic sheets allows for greater flexibility with adhesives, screws, or clamps, whereas acrylic panels may need specialized mounting hardware to maintain structural integrity and aesthetic appeal. Fabrication of acrylic sheets demands attention to edge finishing and stress prevention to avoid cracking, whereas acrylic panels benefit from factory-quality edges, reducing onsite labor and potential errors.

Visual Clarity and Finishing Options

Acrylic sheets offer superior visual clarity with a high light transmission rate of up to 92%, making them ideal for applications requiring crystal-clear transparency. Acrylic panels, while also clear, often come with enhanced finishing options such as textured surfaces, colored tints, and UV-resistant coatings that provide additional aesthetic and protective benefits. Choosing between acrylic sheet and panel depends on whether clarity or customization through finishing options is the priority for the project.

Maintenance and Cleaning Requirements

Acrylic sheets require regular dusting and gentle cleaning with non-abrasive, mild soap and water to maintain clarity and prevent surface scratches, while acrylic panels, often used in larger installations, demand similar care but with more frequent inspections for stress cracks or frame integrity. Avoiding harsh chemicals and abrasive materials is crucial for both acrylic sheets and panels to preserve their transparency and durability. Proper maintenance ensures the longevity of acrylic materials in architectural and display applications.

Choosing the Right Option: Sheet or Panel

Acrylic sheets offer versatility with their thin, lightweight structure ideal for crafting, signage, and protective barriers, while acrylic panels provide greater rigidity and thickness suited for structural applications and architectural features. Selecting between an acrylic sheet and an acrylic panel depends on the project's strength requirements, clarity, and durability needs. Evaluating factors such as thickness, impact resistance, and installation environment ensures the optimal material choice for lasting performance.

Acrylic Sheet vs Acrylic Panel Infographic

materialdif.com

materialdif.com