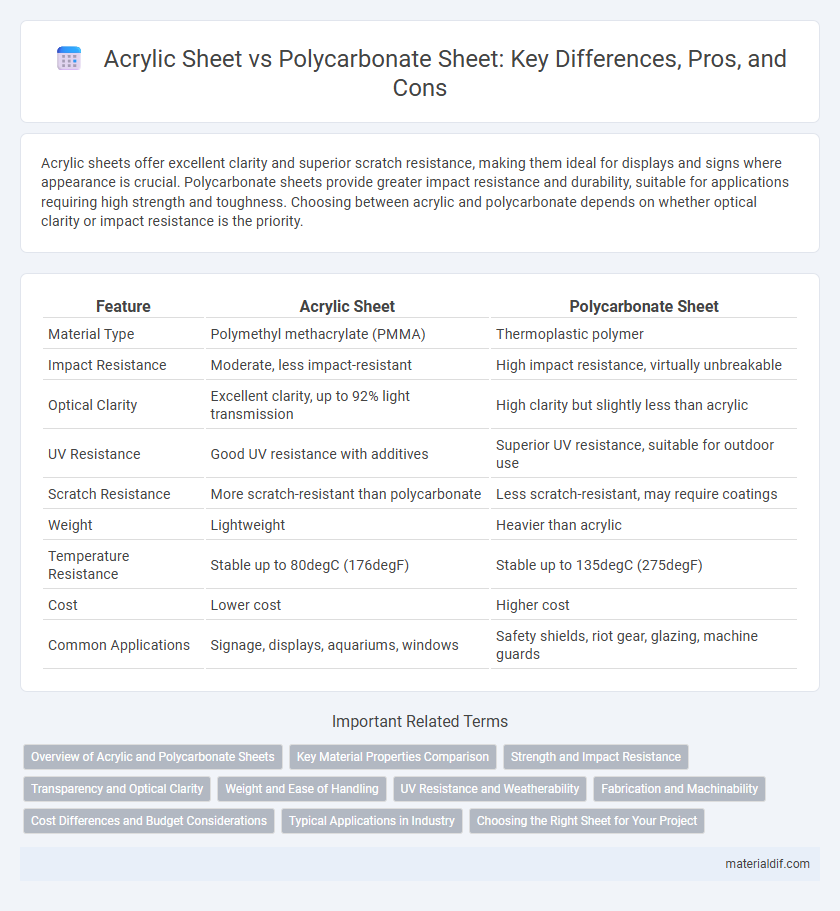

Acrylic sheets offer excellent clarity and superior scratch resistance, making them ideal for displays and signs where appearance is crucial. Polycarbonate sheets provide greater impact resistance and durability, suitable for applications requiring high strength and toughness. Choosing between acrylic and polycarbonate depends on whether optical clarity or impact resistance is the priority.

Table of Comparison

| Feature | Acrylic Sheet | Polycarbonate Sheet |

|---|---|---|

| Material Type | Polymethyl methacrylate (PMMA) | Thermoplastic polymer |

| Impact Resistance | Moderate, less impact-resistant | High impact resistance, virtually unbreakable |

| Optical Clarity | Excellent clarity, up to 92% light transmission | High clarity but slightly less than acrylic |

| UV Resistance | Good UV resistance with additives | Superior UV resistance, suitable for outdoor use |

| Scratch Resistance | More scratch-resistant than polycarbonate | Less scratch-resistant, may require coatings |

| Weight | Lightweight | Heavier than acrylic |

| Temperature Resistance | Stable up to 80degC (176degF) | Stable up to 135degC (275degF) |

| Cost | Lower cost | Higher cost |

| Common Applications | Signage, displays, aquariums, windows | Safety shields, riot gear, glazing, machine guards |

Overview of Acrylic and Polycarbonate Sheets

Acrylic sheets are lightweight, rigid thermoplastics known for their exceptional clarity and UV resistance, making them ideal for windows, displays, and signage. Polycarbonate sheets offer superior impact resistance and higher durability, often used in safety glazing, bulletproof windows, and industrial applications. Both materials provide transparency and weather resistance but differ significantly in strength, flexibility, and cost-effectiveness.

Key Material Properties Comparison

Acrylic sheets offer superior clarity and UV resistance, making them ideal for applications requiring excellent optical properties and outdoor durability. Polycarbonate sheets provide higher impact strength and better heat resistance, suited for environments where toughness and temperature resilience are critical. Both materials are lightweight and versatile, but acrylic excels in scratch resistance while polycarbonate outperforms in flexibility and impact absorption.

Strength and Impact Resistance

Acrylic sheets offer excellent clarity and scratch resistance but have lower impact resistance compared to polycarbonate sheets. Polycarbonate sheets exhibit superior strength, being up to 250 times stronger than glass and significantly more impact-resistant than acrylic, making them ideal for high-impact applications. While acrylic is more rigid, polycarbonate's flexibility under stress enhances its durability and resistance to cracking.

Transparency and Optical Clarity

Acrylic sheets offer superior optical clarity with light transmittance up to 92%, making them ideal for applications requiring high transparency and minimal distortion. Polycarbonate sheets provide good transparency but typically have slightly lower light transmission, around 88-90%, and can exhibit more haze compared to acrylic. Both materials are durable, but acrylic remains the preferred choice when optical clarity and a glass-like finish are paramount.

Weight and Ease of Handling

Acrylic sheets weigh approximately 50% less than glass, making them lighter and easier to handle compared to polycarbonate sheets, which are denser and heavier. The lower weight of acrylic contributes to simpler installation and reduced fatigue during handling, while polycarbonate's increased weight offers enhanced impact resistance but can be more cumbersome. Both materials are manageable, but acrylic excels in applications prioritizing lightweight and ease of maneuverability.

UV Resistance and Weatherability

Acrylic sheets exhibit excellent UV resistance and superior weatherability, maintaining clarity and structural integrity even after prolonged outdoor exposure. Polycarbonate sheets, while impact-resistant, tend to yellow and degrade faster under UV radiation without protective coatings. For applications demanding long-term outdoor durability and UV stability, acrylic sheets offer a more reliable solution.

Fabrication and Machinability

Acrylic sheets offer superior machinability with cleaner edge finishes and easier cutting compared to polycarbonate sheets, which require specialized tools due to their toughness. Fabrication of acrylic involves straightforward processes like thermoforming and laser cutting, making it ideal for precise, decorative applications. Polycarbonate sheets demand more intricate fabrication techniques such as drilling with carbide bits and careful heat bending to avoid cracking, favoring impact-resistant and structural uses.

Cost Differences and Budget Considerations

Acrylic sheets typically cost less than polycarbonate sheets, making them a more budget-friendly option for projects requiring clear, rigid materials. Polycarbonate sheets offer higher impact resistance and durability, which justifies their higher price for applications demanding enhanced strength and safety. Budget considerations should balance the upfront material cost against long-term performance and potential replacement expenses.

Typical Applications in Industry

Acrylic sheets are widely used in retail displays, signage, and lighting fixtures due to their excellent clarity and UV resistance, making them ideal for visual applications where aesthetics are paramount. Polycarbonate sheets are preferred in automotive components, protective barriers, and security glazing because of their superior impact resistance and high tensile strength, ensuring durability in demanding environments. Both materials serve critical roles in construction and manufacturing, with acrylic excelling in decorative and light-transmitting applications, while polycarbonate dominates in tough, safety-critical installations.

Choosing the Right Sheet for Your Project

Acrylic sheets offer superior clarity and UV resistance, making them ideal for outdoor displays and signage, while polycarbonate sheets provide exceptional impact resistance suitable for safety glazing and protective barriers. Consider the project's requirements for strength, transparency, and exposure to environmental factors to determine the best option. Cost-effectiveness and ease of fabrication also influence the choice between acrylic and polycarbonate sheets.

Acrylic Sheet vs Polycarbonate Sheet Infographic

materialdif.com

materialdif.com