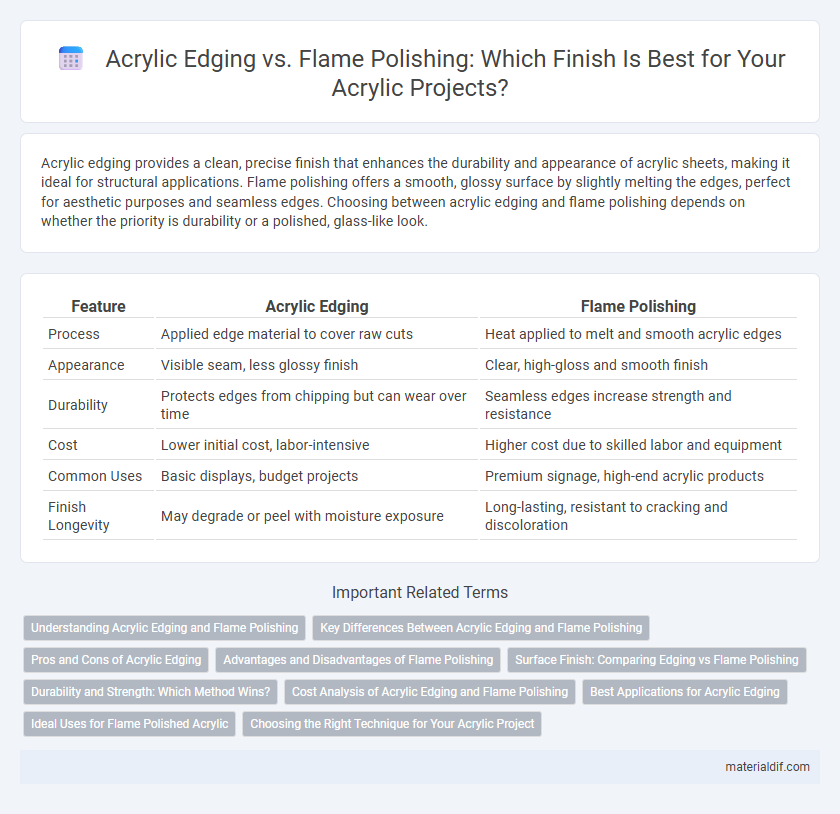

Acrylic edging provides a clean, precise finish that enhances the durability and appearance of acrylic sheets, making it ideal for structural applications. Flame polishing offers a smooth, glossy surface by slightly melting the edges, perfect for aesthetic purposes and seamless edges. Choosing between acrylic edging and flame polishing depends on whether the priority is durability or a polished, glass-like look.

Table of Comparison

| Feature | Acrylic Edging | Flame Polishing |

|---|---|---|

| Process | Applied edge material to cover raw cuts | Heat applied to melt and smooth acrylic edges |

| Appearance | Visible seam, less glossy finish | Clear, high-gloss and smooth finish |

| Durability | Protects edges from chipping but can wear over time | Seamless edges increase strength and resistance |

| Cost | Lower initial cost, labor-intensive | Higher cost due to skilled labor and equipment |

| Common Uses | Basic displays, budget projects | Premium signage, high-end acrylic products |

| Finish Longevity | May degrade or peel with moisture exposure | Long-lasting, resistant to cracking and discoloration |

Understanding Acrylic Edging and Flame Polishing

Acrylic edging involves shaping and smoothing the edges of acrylic sheets to improve appearance and safety, typically achieved through sanding or mechanical polishing. Flame polishing, a specialized technique, uses a controlled flame to heat and melt the acrylic's edges, creating a glossy, transparent finish that enhances clarity and smoothness. Understanding these methods is crucial for selecting the appropriate finishing process based on the desired aesthetic and durability of acrylic products.

Key Differences Between Acrylic Edging and Flame Polishing

Acrylic edging involves mechanically smoothing and shaping the edges using tools like routers or sanders, resulting in a consistent and controlled finish ideal for custom shapes. Flame polishing uses a high-temperature flame to melt the acrylic's surface, creating a glossy, clear edge but requiring skill to avoid distortion or burns. Key differences include the precision and control of mechanical edging versus the polished clarity and speed of flame polishing, with each method suited to different aesthetic and functional needs.

Pros and Cons of Acrylic Edging

Acrylic edging offers a cost-effective and durable solution with a clean, matte finish that reduces light reflection and fingerprints, making it ideal for both functional and aesthetic applications. However, it may lack the high-gloss, smooth surface achieved through flame polishing, and its edges can be slightly less crisp, potentially requiring more maintenance for clarity over time. The choice between acrylic edging and flame polishing depends on the desired appearance, budget constraints, and specific use cases, with acrylic edging providing superior scratch resistance but less optical clarity compared to flame-polished edges.

Advantages and Disadvantages of Flame Polishing

Flame polishing acrylic creates a smooth, glossy finish by melting the edges with a controlled gas flame, enhancing optical clarity compared to other methods. This technique offers superior edge durability and a polished aesthetic but carries risks of overheating, warping, or surface bubbling if not expertly applied. Flame polishing requires specialized skill and equipment, making it less accessible and more time-consuming than simpler mechanical or sanding edges.

Surface Finish: Comparing Edging vs Flame Polishing

Acrylic edging provides a clean, precise edge with consistent thickness, ideal for structural applications requiring durability and uniformity. Flame polishing enhances surface finish by melting the acrylic's edge to create a smooth, glossy appearance, improving optical clarity and reducing micro-scratches. While edging maintains the material's physical integrity, flame polishing elevates aesthetic quality, making it suitable for display or decorative uses.

Durability and Strength: Which Method Wins?

Acrylic edging offers enhanced durability by providing a thicker, more impact-resistant barrier compared to flame polishing, which slightly weakens the acrylic due to heat exposure. Flame polishing delivers a glossy, smooth finish but reduces overall strength, making it more prone to scratches and cracks under stress. For applications demanding maximum toughness and wear resistance, acrylic edging is the superior choice.

Cost Analysis of Acrylic Edging and Flame Polishing

Acrylic edging typically costs less than flame polishing due to the lower labor and equipment expenses involved, with edging prices averaging between $5 to $15 per linear foot compared to flame polishing fees ranging from $10 to $25. Flame polishing demands specialized skills and safety measures, which elevate its operational costs, making it a more premium finishing technique. Cost-effectiveness often drives the choice toward acrylic edging for budget-conscious projects, while flame polishing is preferred when a high-gloss, polished edge justifies the extra investment.

Best Applications for Acrylic Edging

Acrylic edging offers the best applications for projects requiring durable, impact-resistant finishes such as retail displays, signage, and protective barriers due to its clean, consistent edges and ease of customization. It is ideal for thick acrylic sheets where heat distortion from flame polishing can compromise structural integrity. Acrylic edging maintains optical clarity and smoothness while providing enhanced surface protection, making it suitable for environments demanding both aesthetics and functionality.

Ideal Uses for Flame Polished Acrylic

Flame polished acrylic is ideal for applications requiring a smooth, crystal-clear finish on edges, such as in display cases, signage, and high-end retail fixtures. This technique is preferred when optical clarity and a glossy surface are critical, as it eliminates roughness and enhances the acrylic's natural transparency. Flame polishing also strengthens the edges, making it suitable for products exposed to frequent handling or demanding visual standards.

Choosing the Right Technique for Your Acrylic Project

Acrylic edging techniques significantly impact the final appearance and durability of your project, with flame polishing offering a glossy, seamless finish ideal for curved edges, while acrylic edging provides a more matte, textured look better suited for straight cuts. Flame polishing melts the acrylic surface to eliminate scratches and sharpness, enhancing clarity and smoothness, making it preferable for high-quality displays or artistic applications. Choosing the right technique depends on the acrylic project's functional requirements, desired aesthetic, and budget constraints, ensuring optimal performance and visual appeal.

Acrylic Edging vs Flame Polishing Infographic

materialdif.com

materialdif.com