Flame polishing acrylic provides a smooth, glossy finish by briefly exposing the material to a high-temperature flame, which melts and fuses the surface for enhanced clarity and shine. Diamond polishing acrylic uses fine abrasive tools to grind and polish the edges, resulting in a precise, crystal-clear finish ideal for detailed work. While flame polishing is faster and effective for larger surfaces, diamond polishing offers superior edge quality and durability for intricate acrylic projects.

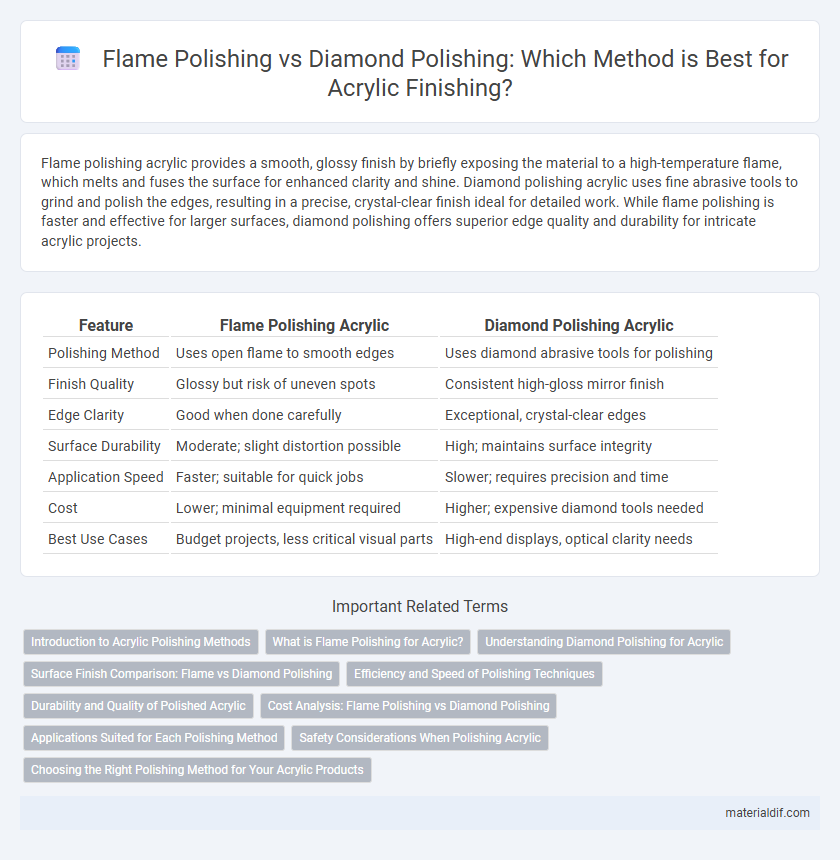

Table of Comparison

| Feature | Flame Polishing Acrylic | Diamond Polishing Acrylic |

|---|---|---|

| Polishing Method | Uses open flame to smooth edges | Uses diamond abrasive tools for polishing |

| Finish Quality | Glossy but risk of uneven spots | Consistent high-gloss mirror finish |

| Edge Clarity | Good when done carefully | Exceptional, crystal-clear edges |

| Surface Durability | Moderate; slight distortion possible | High; maintains surface integrity |

| Application Speed | Faster; suitable for quick jobs | Slower; requires precision and time |

| Cost | Lower; minimal equipment required | Higher; expensive diamond tools needed |

| Best Use Cases | Budget projects, less critical visual parts | High-end displays, optical clarity needs |

Introduction to Acrylic Polishing Methods

Acrylic polishing methods enhance the clarity and smoothness of acrylic surfaces, with flame polishing and diamond polishing as the primary techniques. Flame polishing uses a high-temperature flame to melt the acrylic's surface slightly, creating a glossy, transparent finish ideal for curved edges and quick touch-ups. Diamond polishing involves abrasive diamond tools that mechanically grind and polish the surface, providing a precise and ultra-smooth finish suited for flat edges and complex shapes.

What is Flame Polishing for Acrylic?

Flame polishing acrylic involves heating the material's surface with a controlled gas flame to melt and smooth out imperfections, providing a clear, glossy finish. This technique is ideal for small edges and surfaces, enhancing optical clarity by sealing scratches and reducing haze. Compared to diamond polishing, flame polishing is faster and more cost-effective but is typically limited to simpler shapes and thinner acrylic sheets.

Understanding Diamond Polishing for Acrylic

Diamond polishing acrylic delivers a superior, crystal-clear finish by using fine diamond abrasives that precisely smooth the edges, enhancing clarity and reducing surface imperfections. This technique outperforms flame polishing by preventing heat distortion and maintaining the acrylic's structural integrity. The result is a durable, glossy edge ideal for high-quality displays and professional applications.

Surface Finish Comparison: Flame vs Diamond Polishing

Flame polishing acrylic produces a smooth, glossy surface by briefly exposing the material to high heat, effectively melting away minor imperfections while maintaining edge clarity. Diamond polishing utilizes abrasive pads or wheels to mechanically grind and buff the acrylic surface, resulting in a crystal-clear finish with sharper, more precise edges and increased scratch resistance. While flame polishing is faster and ideal for curved or irregular shapes, diamond polishing delivers superior clarity and durability, especially on flat or complex profiles.

Efficiency and Speed of Polishing Techniques

Flame polishing acrylic offers rapid surface finishing by melting the material's outer layer, delivering a smooth, glossy finish within seconds, making it highly efficient for quick turnaround projects. Diamond polishing acrylic uses abrasive compounds and rotating wheels to achieve a precise, mirror-like finish but requires significantly more time and labor, reducing overall speed. For applications prioritizing efficiency and speed, flame polishing is often preferred, while diamond polishing suits detailed, high-precision finishes despite its longer process.

Durability and Quality of Polished Acrylic

Flame polishing acrylic enhances surface smoothness by melting the edges, creating a glossy finish but may slightly reduce durability due to heat exposure potentially causing minor warping. Diamond polishing acrylic involves abrasive compounds that produce a highly durable, crystal-clear finish without altering the acrylic's structural integrity, resulting in superior optical quality and longevity. For applications requiring maximum durability and premium clarity, diamond polishing typically outperforms flame polishing in preserving acrylic quality over time.

Cost Analysis: Flame Polishing vs Diamond Polishing

Flame polishing acrylic generally incurs lower costs due to its faster processing time and minimal equipment requirements, making it suitable for small-scale or budget-conscious projects. Diamond polishing demands higher initial investment in specialized machinery and skilled labor, resulting in increased expenses but delivering superior finish quality and precision. When comparing cost efficiency, flame polishing is more economical for simpler applications while diamond polishing justifies its cost in high-end or large-scale production with exacting finish standards.

Applications Suited for Each Polishing Method

Flame polishing acrylic is ideal for applications requiring smooth, glossy edges on curved or intricate shapes, such as decorative displays and signage, where the heat melts the surface to create a clear finish. Diamond polishing acrylic is suited for flat or large surfaces needing a precise, high-quality polished edge, commonly used in architectural panels and museum cases for its durability and sharp clarity. Selecting between flame and diamond polishing depends on the acrylic part's geometry and the visual or structural demands of the final product.

Safety Considerations When Polishing Acrylic

Flame polishing acrylic involves using an open flame to melt and smooth the surface, which requires stringent safety measures due to the risk of burns, inhalation of toxic fumes, and fire hazards. Diamond polishing acrylic utilizes abrasive diamond pads, offering a safer alternative by eliminating heat and reducing exposure to harmful vapors, making it ideal for enclosed workspaces. Proper ventilation, use of protective gear, and adherence to safety protocols are crucial regardless of the polishing method to prevent injury and ensure a high-quality finish.

Choosing the Right Polishing Method for Your Acrylic Products

Flame polishing acrylic offers a smooth, glossy finish by lightly melting the surface, ideal for curved edges and quick touch-ups, while diamond polishing employs abrasive pads for a precise, high-quality shine suited for flat surfaces and detailed edges. Choosing the right method depends on the acrylic product's shape, desired finish, and production volume; flame polishing is cost-effective for simple designs, whereas diamond polishing ensures durability and clarity for premium applications. Understanding these differences enhances the aesthetic appeal and longevity of acrylic products in various industries, from signage to display cases.

Flame Polishing Acrylic vs Diamond Polishing Acrylic Infographic

materialdif.com

materialdif.com