Painting acrylic offers vibrant color customization and allows for intricate designs with a smooth finish, making it ideal for artistic and decorative projects. Laser engraving acrylic creates precise, detailed patterns or text through controlled laser etching, providing a permanent and professional look without altering the material's surface color. Choosing between the two depends on the desired aesthetic--painting adds color and texture, while laser engraving emphasizes precision and durability.

Table of Comparison

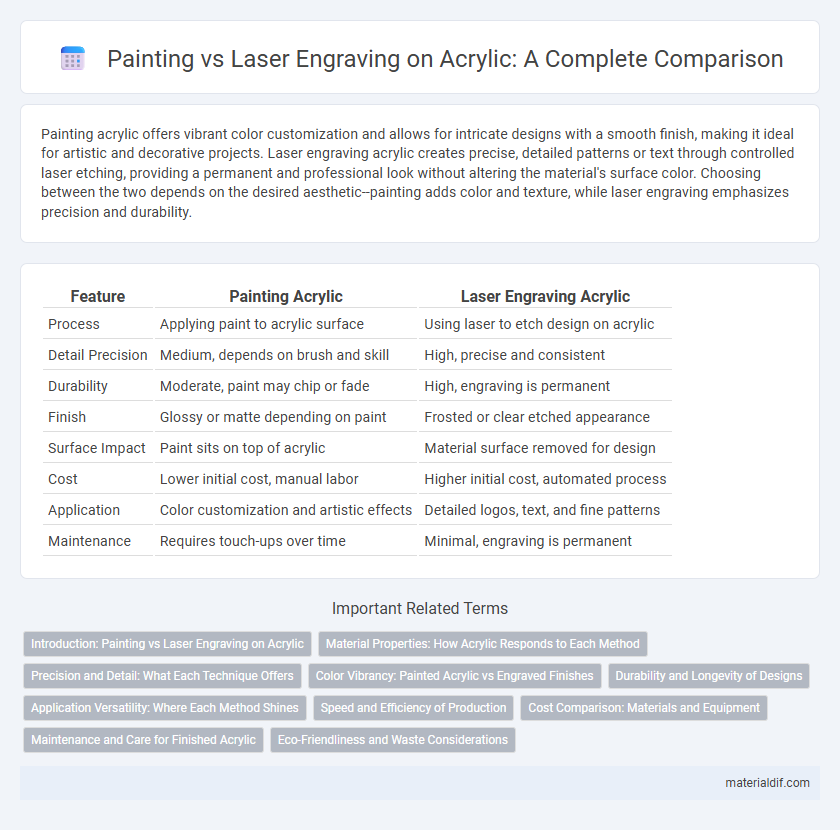

| Feature | Painting Acrylic | Laser Engraving Acrylic |

|---|---|---|

| Process | Applying paint to acrylic surface | Using laser to etch design on acrylic |

| Detail Precision | Medium, depends on brush and skill | High, precise and consistent |

| Durability | Moderate, paint may chip or fade | High, engraving is permanent |

| Finish | Glossy or matte depending on paint | Frosted or clear etched appearance |

| Surface Impact | Paint sits on top of acrylic | Material surface removed for design |

| Cost | Lower initial cost, manual labor | Higher initial cost, automated process |

| Application | Color customization and artistic effects | Detailed logos, text, and fine patterns |

| Maintenance | Requires touch-ups over time | Minimal, engraving is permanent |

Introduction: Painting vs Laser Engraving on Acrylic

Painting acrylic involves applying pigments directly onto the surface, creating vibrant, customizable colors and textures with versatile brushstrokes. Laser engraving acrylic uses high-precision lasers to etch detailed designs by vaporizing the material's surface, producing clean, permanent markings with exceptional clarity. Both methods offer distinct aesthetic results, where painting emphasizes color and texture while laser engraving focuses on precision and durability.

Material Properties: How Acrylic Responds to Each Method

Acrylic's clarity and thickness influence its response to painting and laser engraving, with painted acrylic offering vibrant, opaque finishes that resist fading and maintain surface smoothness. Laser engraving alters acrylic's surface by vaporizing layers, creating precise, translucent etched designs without affecting overall structural integrity. The material's heat resistance and melting point make it suitable for laser engraving, while its chemical inertness ensures paint adheres well without degradation.

Precision and Detail: What Each Technique Offers

Painting acrylic provides bold, vibrant colors but may lack the fine precision achievable with laser engraving. Laser engraving acrylic allows for intricate, highly detailed designs by precisely etching the surface at a microscopic level. Precision in laser engraving surpasses painting by delivering consistent, sharp lines and complex patterns ideal for detailed artwork.

Color Vibrancy: Painted Acrylic vs Engraved Finishes

Painting acrylic produces vibrant, opaque colors that enhance the material's visual appeal with a smooth, glossy finish, making it ideal for artistic and decorative applications. Laser engraving acrylic removes material to create frosted or etched designs that contrast subtly with the base acrylic, providing a sleek, modern look without adding color. Painted acrylic offers broader color customization and saturation, while laser engraving excels in precision and durability for detailed, monochromatic patterns.

Durability and Longevity of Designs

Painting acrylic offers vibrant, customizable finishes but is prone to chipping and fading over time due to exposure to UV light and environmental factors. Laser engraving acrylic creates precise, permanent marks by etching beneath the surface, significantly enhancing durability and resistance to wear and tear. For long-lasting design applications, laser engraving ensures superior longevity compared to painted surfaces, which may require periodic touch-ups to maintain appearance.

Application Versatility: Where Each Method Shines

Painting acrylic offers extensive application versatility by allowing vibrant colors, textures, and detailed designs suitable for artistic and decorative projects. Laser engraving acrylic excels in precision and durability, creating intricate patterns or logos with crisp, permanent markings ideal for industrial, signage, and customization purposes. Each method shines depending on the need for visual creativity or exact, lasting identification on acrylic surfaces.

Speed and Efficiency of Production

Painting acrylic offers slower production speeds due to drying times and manual labor, making it less efficient for high-volume orders. Laser engraving acrylic delivers rapid, precise results with minimal setup, significantly enhancing production efficiency and reducing turnaround times. Manufacturers seeking speed and consistent quality often prefer laser engraving for scalable acrylic customization projects.

Cost Comparison: Materials and Equipment

Painting acrylic typically involves lower upfront costs with affordable brushes, paints, and minimal equipment, making it budget-friendly for small projects. Laser engraving acrylic requires significant investment in a laser machine, which can range from $300 to over $10,000, but offers precise, repeatable designs and reduced labor costs over time. Material costs are comparable, as both techniques use standard acrylic sheets, but laser engraving may incur additional expenses for power consumption and machine maintenance.

Maintenance and Care for Finished Acrylic

Painting acrylic surfaces requires regular dusting and occasional cleaning with a soft, damp cloth to prevent paint chipping and maintain vibrant colors. Laser engraving acrylic demands minimal maintenance, as the engraved areas are resistant to fading and scratches but may benefit from gentle cleaning to preserve clarity. Both finishes should avoid harsh chemicals and abrasive materials to extend the lifespan and appearance of the acrylic.

Eco-Friendliness and Waste Considerations

Painting acrylic involves applying non-toxic, water-based paints that minimize harmful emissions and reduce chemical waste, promoting an eco-friendly art process. Laser engraving acrylic, while precise and efficient, generates small plastic particulates and fumes that require proper ventilation and disposal to mitigate environmental impact. Thoughtful selection of materials and waste management practices significantly influence the overall sustainability of acrylic customization methods.

Painting Acrylic vs Laser Engraving Acrylic Infographic

materialdif.com

materialdif.com