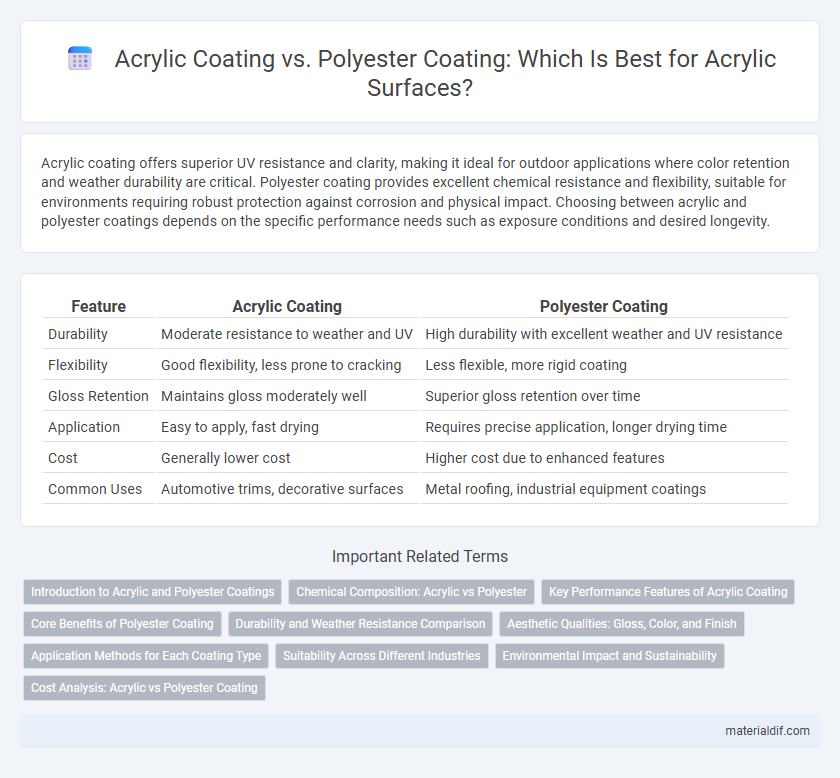

Acrylic coating offers superior UV resistance and clarity, making it ideal for outdoor applications where color retention and weather durability are critical. Polyester coating provides excellent chemical resistance and flexibility, suitable for environments requiring robust protection against corrosion and physical impact. Choosing between acrylic and polyester coatings depends on the specific performance needs such as exposure conditions and desired longevity.

Table of Comparison

| Feature | Acrylic Coating | Polyester Coating |

|---|---|---|

| Durability | Moderate resistance to weather and UV | High durability with excellent weather and UV resistance |

| Flexibility | Good flexibility, less prone to cracking | Less flexible, more rigid coating |

| Gloss Retention | Maintains gloss moderately well | Superior gloss retention over time |

| Application | Easy to apply, fast drying | Requires precise application, longer drying time |

| Cost | Generally lower cost | Higher cost due to enhanced features |

| Common Uses | Automotive trims, decorative surfaces | Metal roofing, industrial equipment coatings |

Introduction to Acrylic and Polyester Coatings

Acrylic coatings provide excellent UV resistance and color retention, making them ideal for outdoor applications such as automotive finishes and architectural surfaces. Polyester coatings offer superior chemical resistance and durability, often used in industrial environments requiring long-lasting protection against corrosion and weathering. Both coatings utilize polymer chemistry to enhance surface properties but differ in their performance characteristics and optimal usage scenarios.

Chemical Composition: Acrylic vs Polyester

Acrylic coatings primarily consist of polymerized acrylic acid or methacrylic acid esters, which provide excellent UV resistance and flexibility. Polyester coatings are composed of long-chain polyester resins formed by the condensation of polyols and dicarboxylic acids, offering superior hardness and chemical resistance. The differing chemical structures influence their performance in applications, with acrylics favoring weatherability and polyesters excelling in durability and protection against solvents.

Key Performance Features of Acrylic Coating

Acrylic coating offers superior UV resistance, ensuring long-lasting color retention and durability in outdoor applications compared to polyester coating. Its excellent adhesion properties provide a strong bond to various substrates, enhancing corrosion protection and surface toughness. Acrylic coatings also exhibit better flexibility, reducing the risk of cracking or peeling under temperature fluctuations and mechanical stress.

Core Benefits of Polyester Coating

Polyester coatings offer superior weather resistance and excellent UV stability, making them ideal for outdoor applications where durability is crucial. Their exceptional flexibility and chemical resistance contribute to long-lasting protection against corrosion and environmental damage. Compared to acrylic coatings, polyester coatings provide enhanced surface hardness and better adhesion to metals, ensuring a more resilient finish.

Durability and Weather Resistance Comparison

Acrylic coatings offer excellent UV resistance and flexibility, reducing cracking and chalking over time, which enhances weather resistance especially in harsh sunlight. Polyester coatings provide superior durability against abrasion and chemical exposure, making them highly effective for environments subjected to mechanical wear. While acrylic coatings excel in resisting color fading and maintaining surface integrity, polyester coatings outperform in long-term toughness and resistance to environmental pollutants.

Aesthetic Qualities: Gloss, Color, and Finish

Acrylic coatings provide superior gloss and vibrant color retention, maintaining a bright, clear finish over time, making them ideal for applications demanding high aesthetic appeal. Polyester coatings offer a durable finish with good color stability but generally exhibit a less glossy, more matte appearance compared to acrylics. The choice between acrylic and polyester coatings depends on the desired balance between long-lasting color vibrancy and surface finish aesthetics.

Application Methods for Each Coating Type

Acrylic coatings are commonly applied using spray, brush, or roller methods, offering excellent versatility for detailed surfaces and quick drying times suitable for both indoor and outdoor applications. Polyester coatings typically require spray application to ensure a smooth, even finish and are preferred for industrial uses due to their superior chemical and weather resistance. Choosing the right application method depends on the coating type, surface material, and environmental exposure to maximize durability and aesthetic quality.

Suitability Across Different Industries

Acrylic coatings offer excellent UV resistance and flexibility, making them ideal for automotive and architectural applications where weather durability is crucial. Polyester coatings provide superior chemical and abrasion resistance, preferred in industrial and marine industries requiring robust protection against harsh environments. Both coatings serve distinct purposes, with acrylics favored for aesthetic finishes and polyesters chosen for heavy-duty performance.

Environmental Impact and Sustainability

Acrylic coatings generate lower volatile organic compound (VOC) emissions compared to polyester coatings, reducing air pollution and health risks. Acrylic is often water-based and biodegradable, enabling easier recycling and minimal environmental footprint. Polyester coatings typically rely on solvent-based formulas, increasing environmental hazards and complicating waste management.

Cost Analysis: Acrylic vs Polyester Coating

Acrylic coatings typically offer a lower initial cost compared to polyester coatings, making them an attractive option for budget-conscious projects. Polyester coatings provide greater durability and weather resistance, which can result in lower maintenance and replacement expenses over time. When evaluating total lifecycle costs, polyester coatings often deliver better long-term value despite their higher upfront price.

Acrylic Coating vs Polyester Coating Infographic

materialdif.com

materialdif.com