Acrylic laminate offers a high-gloss finish with superior clarity and resistance to yellowing, making it ideal for modern, sleek surfaces. High pressure laminate provides enhanced durability against impact and heat, suitable for heavy-use areas requiring robust protection. Choosing between acrylic laminate and high pressure laminate depends on the desired aesthetic and functional demands of the project.

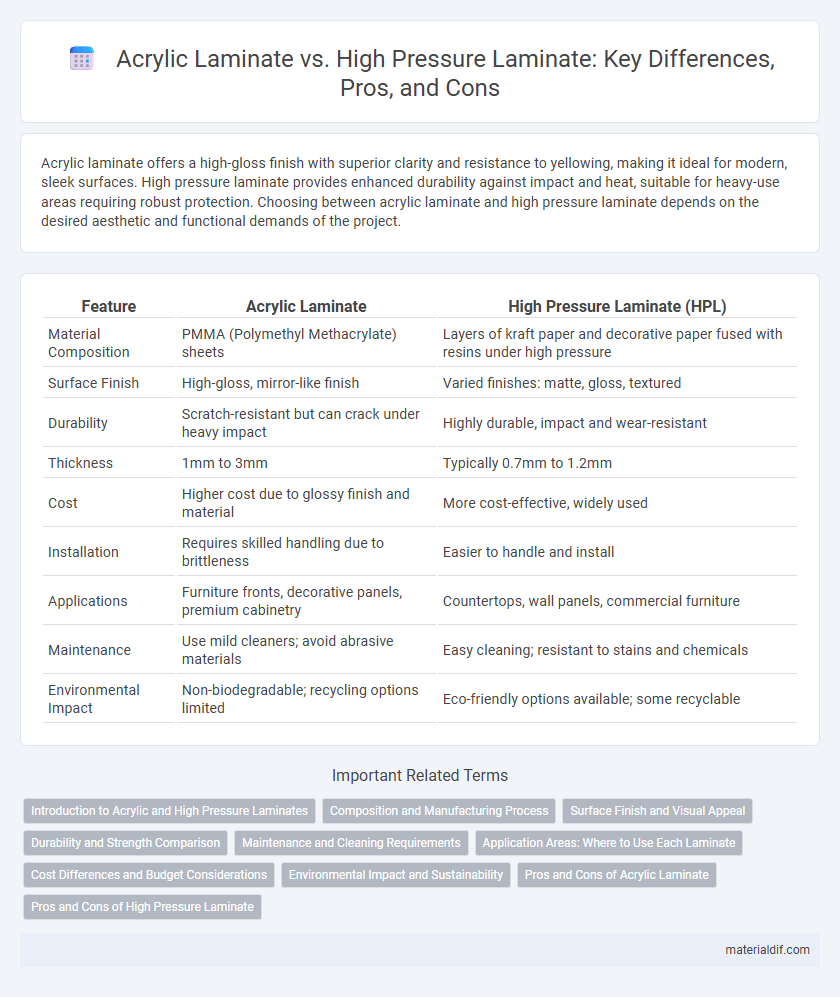

Table of Comparison

| Feature | Acrylic Laminate | High Pressure Laminate (HPL) |

|---|---|---|

| Material Composition | PMMA (Polymethyl Methacrylate) sheets | Layers of kraft paper and decorative paper fused with resins under high pressure |

| Surface Finish | High-gloss, mirror-like finish | Varied finishes: matte, gloss, textured |

| Durability | Scratch-resistant but can crack under heavy impact | Highly durable, impact and wear-resistant |

| Thickness | 1mm to 3mm | Typically 0.7mm to 1.2mm |

| Cost | Higher cost due to glossy finish and material | More cost-effective, widely used |

| Installation | Requires skilled handling due to brittleness | Easier to handle and install |

| Applications | Furniture fronts, decorative panels, premium cabinetry | Countertops, wall panels, commercial furniture |

| Maintenance | Use mild cleaners; avoid abrasive materials | Easy cleaning; resistant to stains and chemicals |

| Environmental Impact | Non-biodegradable; recycling options limited | Eco-friendly options available; some recyclable |

Introduction to Acrylic and High Pressure Laminates

Acrylic laminate, known for its high gloss finish and superior scratch resistance, is made by applying a thin layer of acrylic resin over a substrate, offering enhanced durability and vibrant aesthetics. High Pressure Laminate (HPL) consists of multiple layers of kraft paper impregnated with resins, fused under high temperature and pressure to create a robust and versatile surface widely used in cabinetry and furniture. Both materials deliver distinct advantages in interior design, with acrylic laminate providing a sleek, modern look while HPL offers increased impact resistance and cost-effectiveness.

Composition and Manufacturing Process

Acrylic laminate is composed of a polymer resin that is cast into thin, smooth sheets using a solvent-based process, resulting in a high-gloss, durable finish with natural depth and color richness. High Pressure Laminate (HPL) is made by compressing layers of kraft paper impregnated with phenolic resin under high heat and pressure, producing a dense and robust panel with exceptional impact and scratch resistance. The key difference lies in acrylic's cast polymer composition versus HPL's layered paper and resin structure, which influences their surface finish, durability, and application suitability.

Surface Finish and Visual Appeal

Acrylic laminate offers a high-gloss, mirror-like surface finish that enhances visual appeal with its deep, vibrant colors and seamless edges, making it ideal for modern, sleek designs. High pressure laminate (HPL) provides a durable, textured surface with varied finishes such as matte, satin, and semi-gloss, offering versatility in aesthetics but less gloss intensity compared to acrylic. The superior clarity and reflectivity of acrylic laminate make it the preferred choice for premium applications demanding exceptional surface brilliance and color depth.

Durability and Strength Comparison

Acrylic laminate offers superior scratch resistance and long-lasting gloss compared to high pressure laminate, making it ideal for surfaces exposed to frequent use. High pressure laminate, composed of multiple layers of resin-impregnated paper, provides robust impact resistance and structural rigidity suitable for heavy-duty applications. Both materials deliver excellent durability, but acrylic laminate excels in maintaining aesthetic appeal over time, while high pressure laminate focuses on strength under physical stress.

Maintenance and Cleaning Requirements

Acrylic Laminate offers a smooth, non-porous surface that resists stains and requires only gentle cleaning with mild soap and water to maintain its glossy finish. High Pressure Laminate demands more frequent maintenance, including careful use of non-abrasive cleaners to avoid surface scratches and potential delamination. Both materials benefit from immediate spill cleanup, but Acrylic Laminate generally provides easier upkeep with less risk of surface damage over time.

Application Areas: Where to Use Each Laminate

Acrylic laminate excels in high-end applications such as kitchen cabinets, furniture, and wall panels due to its superior gloss, scratch resistance, and UV stability. High Pressure Laminate (HPL) is ideal for heavy-use areas including commercial interiors, countertops, and flooring, offering enhanced durability and impact resistance. Selecting between acrylic and HPL depends on balancing aesthetic demands with functional performance requirements.

Cost Differences and Budget Considerations

Acrylic laminate typically costs more than high pressure laminate (HPL) due to its higher gloss finish and superior durability, making it a premium choice for modern cabinetry and furniture. High pressure laminate offers a more budget-friendly option with reasonable durability and a wide range of design options, ideal for cost-sensitive projects. When considering budget, prioritizing acrylic laminate can increase upfront costs but may provide longer-term value through enhanced aesthetics and scratch resistance.

Environmental Impact and Sustainability

Acrylic laminate offers superior durability and recyclability compared to high pressure laminate (HPL), which relies on phenolic resins with higher environmental footprints. The low VOC emissions and longer lifespan of acrylic laminate reduce waste and contribute to better indoor air quality in sustainable building projects. HPL's production process involves more energy consumption and generates greater greenhouse gas emissions, making acrylic laminate a more eco-friendly choice for green design.

Pros and Cons of Acrylic Laminate

Acrylic laminate offers superior gloss and clarity, providing a highly reflective, smooth surface ideal for modern, high-end cabinetry and furniture, while its UV resistance ensures color stability over time. However, acrylic sheets are more prone to scratches and can be more expensive compared to high pressure laminate (HPL), which is more durable and resistant to impact and heat. The ease of repair and ability to achieve seamless edges make acrylic laminate a preferred choice for aesthetic quality despite the trade-offs in durability and cost.

Pros and Cons of High Pressure Laminate

High Pressure Laminate (HPL) offers superior durability and resistance to scratches, heat, and moisture compared to acrylic laminate, making it ideal for heavy-use environments. However, HPL lacks the high gloss finish and seamless appearance that acrylic laminate provides, which may limit its appeal in design-focused applications. While HPL is generally more affordable and thicker, its rigidity can restrict edge detailing options compared to the flexible nature of acrylic laminates.

Acrylic Laminate vs High Pressure Laminate Infographic

materialdif.com

materialdif.com