Acrylic offers superior clarity, UV resistance, and weather durability compared to ABS, making it ideal for applications where transparency and outdoor longevity are critical. While ABS provides better impact resistance and flexibility, it tends to yellow and degrade under prolonged sunlight exposure. Choosing between acrylic and ABS depends on whether optical clarity or impact resilience is the priority for the specific project.

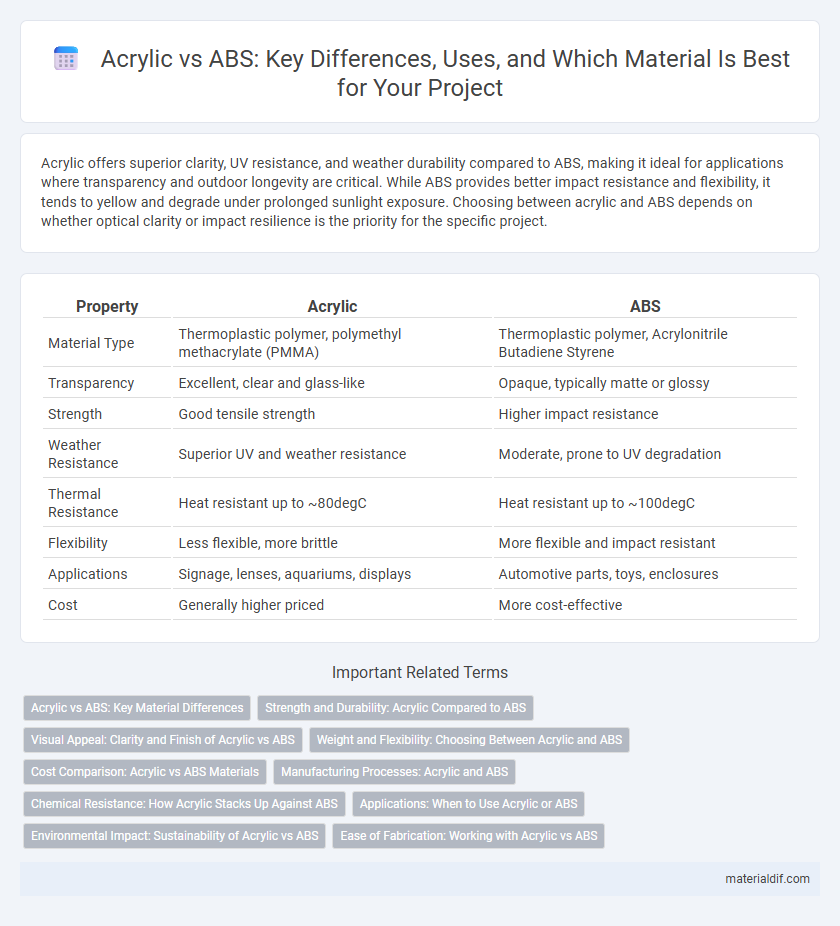

Table of Comparison

| Property | Acrylic | ABS |

|---|---|---|

| Material Type | Thermoplastic polymer, polymethyl methacrylate (PMMA) | Thermoplastic polymer, Acrylonitrile Butadiene Styrene |

| Transparency | Excellent, clear and glass-like | Opaque, typically matte or glossy |

| Strength | Good tensile strength | Higher impact resistance |

| Weather Resistance | Superior UV and weather resistance | Moderate, prone to UV degradation |

| Thermal Resistance | Heat resistant up to ~80degC | Heat resistant up to ~100degC |

| Flexibility | Less flexible, more brittle | More flexible and impact resistant |

| Applications | Signage, lenses, aquariums, displays | Automotive parts, toys, enclosures |

| Cost | Generally higher priced | More cost-effective |

Acrylic vs ABS: Key Material Differences

Acrylic offers superior clarity and weather resistance compared to ABS, making it ideal for outdoor and display applications where transparency and UV stability are crucial. ABS provides greater impact resistance and thermal insulation, suitable for parts requiring durability and heat resistance, such as automotive components. The choice between acrylic and ABS depends on application-specific requirements including optical clarity, mechanical strength, and exposure conditions.

Strength and Durability: Acrylic Compared to ABS

Acrylic exhibits higher tensile strength and superior resistance to UV light and weathering compared to ABS, making it more durable for outdoor applications. ABS offers better impact resistance and flexibility, which is advantageous for parts subject to heavy mechanical stress. The choice between acrylic and ABS depends on the specific balance of strength and durability requirements in the intended use.

Visual Appeal: Clarity and Finish of Acrylic vs ABS

Acrylic offers superior visual appeal compared to ABS due to its exceptional clarity and high-gloss finish, making it ideal for applications requiring transparency and a polished look. ABS tends to have a duller, opaque surface with a matte finish, which limits its use in design-centric products where aesthetics are critical. The inherent transparency and smooth surface of acrylic make it a preferred choice for displays, signage, and decorative elements over ABS.

Weight and Flexibility: Choosing Between Acrylic and ABS

Acrylic is lighter and more rigid compared to ABS, which is heavier but offers better flexibility and impact resistance. Choose acrylic for applications requiring transparency and stiffness, while ABS suits projects needing durability and shock absorption. Weight-sensitive designs benefit from acrylic's low density, whereas flexible parts rely on ABS's superior elasticity.

Cost Comparison: Acrylic vs ABS Materials

Acrylic generally offers a lower cost compared to ABS, making it a budget-friendly choice for applications requiring clarity and rigidity. ABS tends to be more expensive due to its superior impact resistance and durability, which justify the higher investment in high-stress or structural uses. Evaluating cost-effectiveness depends on balancing material price with performance needs specific to the project.

Manufacturing Processes: Acrylic and ABS

Acrylic and ABS differ significantly in manufacturing processes, with acrylic typically produced through polymerization of methyl methacrylate monomers via bulk or continuous casting, injection molding, or extrusion methods. ABS is commonly manufactured using injection molding and extrusion, leveraging its thermoplastic properties to create durable and impact-resistant parts. The choice between acrylic and ABS in production depends on required clarity, strength, and flexibility, as acrylic offers superior optical clarity while ABS provides enhanced toughness and easier machinability.

Chemical Resistance: How Acrylic Stacks Up Against ABS

Acrylic exhibits superior chemical resistance compared to ABS, particularly against diluted acids, alkalis, and solvents like alcohols and ketones. Unlike ABS, which can degrade or discolor when exposed to harsh chemicals, acrylic maintains its clarity and structural integrity, making it ideal for applications requiring frequent contact with cleaning agents or chemical solutions. This enhanced chemical resistance contributes to acrylic's suitability in medical devices, aquarium panels, and protective barriers where durability and transparency are critical.

Applications: When to Use Acrylic or ABS

Acrylic excels in applications requiring clarity and weather resistance, such as transparent panels, display cases, and signage, due to its excellent optical properties and UV stability. ABS is preferred for impact-resistant and durable components like automotive parts, toys, and electronic housings, benefiting from its toughness and ease of machining. Choose acrylic for aesthetic and outdoor uses, while ABS suits functional, high-stress environments.

Environmental Impact: Sustainability of Acrylic vs ABS

Acrylic is more environmentally sustainable than ABS due to its higher recyclability and lower toxicity during production and disposal. While ABS releases harmful chemicals like styrene when incinerated, acrylic decomposes into less hazardous substances, reducing environmental pollution. Furthermore, acrylic's production process consumes less energy and generates fewer greenhouse gas emissions compared to ABS, making it a greener choice for sustainable applications.

Ease of Fabrication: Working with Acrylic vs ABS

Acrylic offers superior clarity and can be easily shaped, cut, and bonded using simple tools, making it ideal for precision fabrication. ABS, while tougher and more impact-resistant, requires higher temperatures and specialized equipment for molding and welding. The ease of machining and adhesion in acrylic supports more versatile and detailed fabrication processes compared to ABS.

Acrylic vs ABS Infographic

materialdif.com

materialdif.com