Acrylic rods offer superior clarity and rigidity compared to polypropylene rods, making them ideal for applications requiring transparency and strength. Polypropylene rods provide greater chemical resistance and flexibility, suitable for environments exposed to harsh chemicals or impact. Choosing between these materials depends on the specific demands of clarity, durability, and environmental resistance in your project.

Table of Comparison

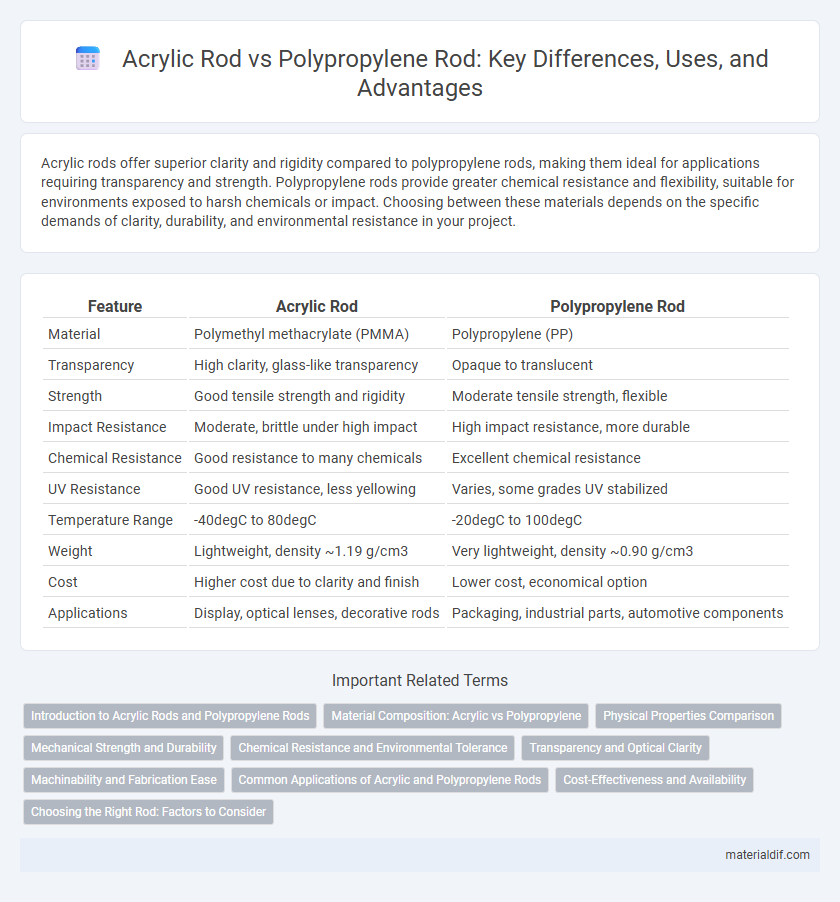

| Feature | Acrylic Rod | Polypropylene Rod |

|---|---|---|

| Material | Polymethyl methacrylate (PMMA) | Polypropylene (PP) |

| Transparency | High clarity, glass-like transparency | Opaque to translucent |

| Strength | Good tensile strength and rigidity | Moderate tensile strength, flexible |

| Impact Resistance | Moderate, brittle under high impact | High impact resistance, more durable |

| Chemical Resistance | Good resistance to many chemicals | Excellent chemical resistance |

| UV Resistance | Good UV resistance, less yellowing | Varies, some grades UV stabilized |

| Temperature Range | -40degC to 80degC | -20degC to 100degC |

| Weight | Lightweight, density ~1.19 g/cm3 | Very lightweight, density ~0.90 g/cm3 |

| Cost | Higher cost due to clarity and finish | Lower cost, economical option |

| Applications | Display, optical lenses, decorative rods | Packaging, industrial parts, automotive components |

Introduction to Acrylic Rods and Polypropylene Rods

Acrylic rods are known for their excellent optical clarity, high impact resistance, and weatherability, making them ideal for display cases, signage, and lighting applications. Polypropylene rods offer superior chemical resistance, flexibility, and low density, suitable for automotive parts, laboratory equipment, and packaging components. Comparing acrylic and polypropylene rods, acrylic provides better visual aesthetics and rigidity, while polypropylene excels in durability and resistance to harsh environments.

Material Composition: Acrylic vs Polypropylene

Acrylic rods are composed of polymethyl methacrylate (PMMA), a transparent thermoplastic known for its optical clarity and resistance to UV light, making them ideal for applications requiring high visual appeal and durability. Polypropylene rods, made from a semi-crystalline polymer, offer superior chemical resistance, flexibility, and impact strength but lack the transparency of acrylic, making them suitable for mechanical parts and industrial components. The choice between acrylic and polypropylene rods depends on the need for optical clarity versus toughness and chemical resistance.

Physical Properties Comparison

Acrylic rods exhibit higher rigidity and better optical clarity compared to polypropylene rods, making them ideal for applications requiring transparency and stiffness. While acrylic has a tensile strength of approximately 75 MPa and a density of 1.18 g/cm3, polypropylene rods offer lower tensile strength around 30 MPa and a lighter density of 0.90 g/cm3, emphasizing their flexibility and chemical resistance. The glass transition temperature of acrylic is about 105degC, significantly higher than polypropylene's 0degC, indicating superior thermal stability for acrylic rods.

Mechanical Strength and Durability

Acrylic rods exhibit superior mechanical strength compared to polypropylene rods, with higher tensile strength and rigidity making them ideal for load-bearing applications. Acrylic provides enhanced durability under UV exposure and environmental stress, retaining clarity and structural integrity longer than polypropylene. Polypropylene rods, while more flexible and impact-resistant, generally offer lower tensile strength and are less suitable for long-term mechanical load scenarios.

Chemical Resistance and Environmental Tolerance

Acrylic rods exhibit superior chemical resistance against acids, alkalis, and solvents compared to polypropylene rods, making them ideal for harsh chemical environments. Polypropylene rods demonstrate excellent environmental tolerance, including resistance to UV radiation and moisture, which provides durability in outdoor and wet conditions. Despite acrylic's brittleness, its clarity and chemical inertness make it preferable for applications demanding both visual quality and robust chemical resistance.

Transparency and Optical Clarity

Acrylic rods exhibit superior transparency and optical clarity compared to polypropylene rods, delivering up to 92% light transmission that closely resembles glass. Polypropylene rods tend to have lower clarity with a more opaque and hazy appearance, making them less suitable for applications requiring clear visibility. The exceptional light transmission and minimal distortion of acrylic rods make them ideal for display cases, lenses, and lighting fixtures.

Machinability and Fabrication Ease

Acrylic rods offer superior machinability due to their hardness and clarity, allowing for precise cutting, drilling, and polishing without cracking or chipping. Polypropylene rods are softer and more flexible, which can complicate machining processes and result in rougher edges or deformation under stress. For fabrication tasks requiring high detail and smooth finishes, acrylic rods are generally preferred, while polypropylene rods are better suited for applications needing chemical resistance and impact flexibility.

Common Applications of Acrylic and Polypropylene Rods

Acrylic rods are commonly used in optical displays, aquariums, and automotive lighting due to their excellent clarity, weather resistance, and UV stability. Polypropylene rods find frequent applications in packaging machinery components, chemical tanks, and food processing equipment because of their outstanding chemical resistance, flexibility, and moisture barrier properties. Both materials serve critical roles in manufacturing, with acrylic excelling in visual and decorative uses while polypropylene is preferred for chemical and industrial environments.

Cost-Effectiveness and Availability

Acrylic rods generally offer higher clarity and durability compared to polypropylene rods, making them suitable for applications requiring optical transparency, but they come at a higher price point. Polypropylene rods are more cost-effective and widely available, especially for industrial and chemical applications due to their resistance to corrosion and lower manufacturing costs. Choosing between acrylic and polypropylene rods depends on balancing budget constraints with the specific performance requirements of the project.

Choosing the Right Rod: Factors to Consider

When choosing between an acrylic rod and a polypropylene rod, consider factors such as transparency, strength, and chemical resistance. Acrylic rods offer superior clarity and higher tensile strength, making them ideal for applications requiring optical clarity and rigidity. Polypropylene rods provide excellent chemical resistance and flexibility, suited for environments involving exposure to harsh chemicals or impact.

Acrylic Rod vs Polypropylene Rod Infographic

materialdif.com

materialdif.com