Acrylic fiber is a synthetic textile material known for its softness, warmth, and resistance to moisture, commonly used in clothing and upholstery. Acrylic resin, on the other hand, is a durable, transparent plastic material utilized in manufacturing items like signs, displays, and protective barriers due to its strong impact resistance and clarity. Understanding the differences between acrylic fiber and acrylic resin is essential for selecting the appropriate type for either fabric applications or rigid plastic products.

Table of Comparison

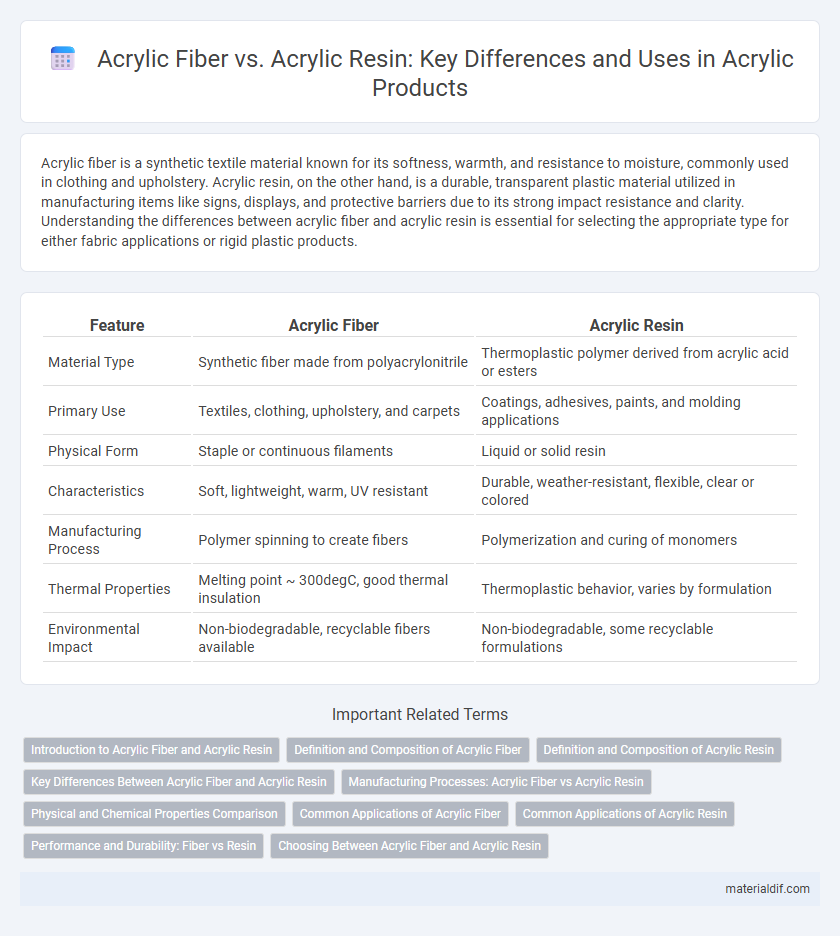

| Feature | Acrylic Fiber | Acrylic Resin |

|---|---|---|

| Material Type | Synthetic fiber made from polyacrylonitrile | Thermoplastic polymer derived from acrylic acid or esters |

| Primary Use | Textiles, clothing, upholstery, and carpets | Coatings, adhesives, paints, and molding applications |

| Physical Form | Staple or continuous filaments | Liquid or solid resin |

| Characteristics | Soft, lightweight, warm, UV resistant | Durable, weather-resistant, flexible, clear or colored |

| Manufacturing Process | Polymer spinning to create fibers | Polymerization and curing of monomers |

| Thermal Properties | Melting point ~ 300degC, good thermal insulation | Thermoplastic behavior, varies by formulation |

| Environmental Impact | Non-biodegradable, recyclable fibers available | Non-biodegradable, some recyclable formulations |

Introduction to Acrylic Fiber and Acrylic Resin

Acrylic fiber is a synthetic textile fiber made from polymerization of acrylonitrile, widely used in clothing and upholstery for its wool-like feel and resistance to wrinkles and sunlight. Acrylic resin, on the other hand, is a thermoplastic or thermosetting polymer used in coatings, adhesives, and plastics due to its clarity, weather resistance, and strong bonding properties. Both materials originate from acrylic polymers but differ significantly in structure and application, with fibers engineered for fabric production and resins designed for industrial and manufacturing uses.

Definition and Composition of Acrylic Fiber

Acrylic fiber is a synthetic fiber made from a polymer containing at least 85% acrylonitrile units, primarily used in textiles for its wool-like feel and durability. In contrast, acrylic resin is a plastic material created through the polymerization of acrylic acid esters and is commonly applied in coatings, adhesives, and plastics. The distinct composition of acrylic fiber--polyacrylonitrile-based polymers--gives it unique properties compared to the varied chemical structures found in acrylic resin formulations.

Definition and Composition of Acrylic Resin

Acrylic resin is a synthetic polymer derived from the polymerization of acrylate monomers such as methyl methacrylate, characterized by a strong, transparent, and weather-resistant composition widely used in coatings, adhesives, and plastics. Unlike acrylic fiber, which is a textile made from polymerized acrylonitrile fibers known for softness and wool-like feel, acrylic resin forms solid materials with high durability and chemical resistance. The composition of acrylic resin typically includes methacrylate esters and cross-linking agents, enabling versatile applications in manufacturing and construction industries.

Key Differences Between Acrylic Fiber and Acrylic Resin

Acrylic fiber is a synthetic textile made from polymer fibers primarily used in clothing and upholstery due to its softness and durability, whereas acrylic resin is a thermoplastic used in manufacturing, coatings, and adhesives for its clarity and chemical resistance. Acrylic fiber is processed through polymerization to create long, flexible fibers, while acrylic resin is formed into solid or semi-solid materials for molding and casting applications. The key differences lie in their physical state, applications, and mechanical properties, with fibers emphasizing tensile strength and flexibility and resins offering structural integrity and chemical stability.

Manufacturing Processes: Acrylic Fiber vs Acrylic Resin

Acrylic fiber is produced through a wet or dry spinning process where polyacrylonitrile polymers are dissolved and extruded to form fine, continuous filaments suitable for textiles. In contrast, acrylic resin manufacturing involves polymerization of acrylate monomers via bulk, suspension, or emulsion polymerization techniques to create solid plastic materials used in coatings and adhesives. The fiber production emphasizes fiber extrusion and elongation for mechanical properties, whereas resin production focuses on controlling molecular weight and polymer architecture for thermal and chemical performance.

Physical and Chemical Properties Comparison

Acrylic fiber, a synthetic polymer primarily composed of polyacrylonitrile, exhibits high tensile strength, flexibility, and excellent resistance to UV radiation and chemical solvents, making it suitable for textiles and upholstery. Acrylic resin, formed through polymerization of acrylate monomers, features superior hardness, thermal stability, and chemical resistance, commonly utilized in coatings, adhesives, and molded products. Both materials share the core acrylonitrile backbone, but acrylic fiber emphasizes mechanical durability and elasticity, while acrylic resin prioritizes rigidity and thermal endurance.

Common Applications of Acrylic Fiber

Acrylic fiber is primarily used in textiles for manufacturing clothing, upholstery, and outdoor fabrics due to its wool-like feel, durability, and resistance to moisture and chemicals. It is a popular material for sweaters, hats, and blankets, as well as in upholstery and carpeting, offering insulation and colorfastness. Unlike acrylic resin, which is utilized in coatings, adhesives, and plastic products, acrylic fiber's common applications are centered around soft, flexible materials for apparel and home furnishings.

Common Applications of Acrylic Resin

Acrylic resin, a versatile polymer known for its clarity and durability, is widely used in applications such as paints, coatings, adhesives, and sealants due to its excellent weather resistance and strong bonding properties. It also plays a crucial role in manufacturing acrylic sheets, lenses, and automotive parts, where optical clarity and impact resistance are essential. Unlike acrylic fiber, which is primarily utilized in textiles for clothing and upholstery, acrylic resin serves industrial and commercial purposes requiring rigid, transparent, or protective materials.

Performance and Durability: Fiber vs Resin

Acrylic fiber offers excellent elasticity, moisture-wicking properties, and resistance to UV light, making it ideal for textiles requiring durability and comfort. Acrylic resin provides superior chemical resistance, hardness, and weatherability, primarily used in coatings and adhesives where long-term environmental exposure occurs. While acrylic fibers excel in flexibility and wear resistance, acrylic resins dominate in structural performance and corrosion resistance.

Choosing Between Acrylic Fiber and Acrylic Resin

Choosing between acrylic fiber and acrylic resin depends on the application requirements: acrylic fiber offers lightweight, durable, and breathable textiles commonly used in clothing and upholstery, while acrylic resin provides a hard, transparent, and versatile thermoplastic ideal for coatings, adhesives, and molded products. Acrylic fiber excels in flexibility and moisture-wicking properties, making it suitable for textile manufacturing, whereas acrylic resin is preferred for structural uses due to its chemical resistance and optical clarity. Evaluating factors such as mechanical strength, environmental exposure, and end-use functionality guides the selection process between these two forms of acrylic materials.

Acrylic Fiber vs Acrylic Resin Infographic

materialdif.com

materialdif.com