Perspex and Plexiglas are both popular brands of acrylic sheet known for their clarity and durability, often used as alternatives to glass. Perspex offers exceptional UV resistance making it ideal for outdoor applications, while Plexiglas is renowned for its superior impact strength and scratch resistance in industrial settings. Choosing between Perspex and Plexiglas depends on the specific needs of your project, such as exposure to sunlight or the level of physical stress the material must endure.

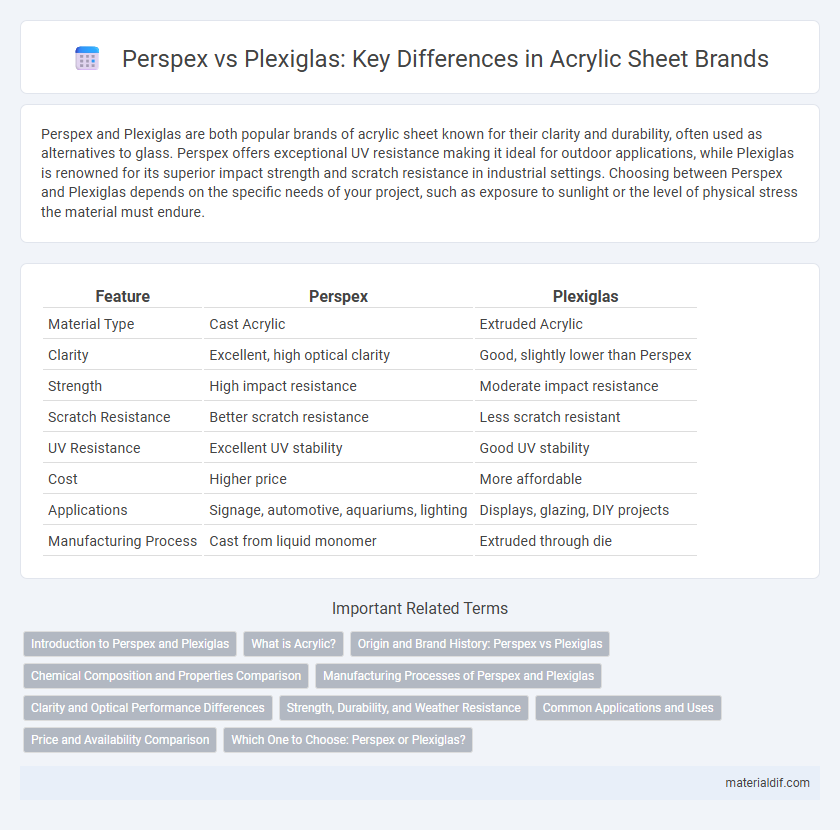

Table of Comparison

| Feature | Perspex | Plexiglas |

|---|---|---|

| Material Type | Cast Acrylic | Extruded Acrylic |

| Clarity | Excellent, high optical clarity | Good, slightly lower than Perspex |

| Strength | High impact resistance | Moderate impact resistance |

| Scratch Resistance | Better scratch resistance | Less scratch resistant |

| UV Resistance | Excellent UV stability | Good UV stability |

| Cost | Higher price | More affordable |

| Applications | Signage, automotive, aquariums, lighting | Displays, glazing, DIY projects |

| Manufacturing Process | Cast from liquid monomer | Extruded through die |

Introduction to Perspex and Plexiglas

Perspex and Plexiglas are leading brand names for cast acrylic sheets known for their exceptional clarity, durability, and versatility in various applications such as signage, glazing, and displays. Perspex, developed in the UK, is renowned for its high optical quality and resistance to UV light, making it ideal for outdoor use, while Plexiglas, originating from Germany, offers superior impact resistance and weatherability. Both materials are thermoplastic polymers composed of polymethyl methacrylate (PMMA), providing lightweight alternatives to glass with excellent transparency and easy machinability.

What is Acrylic?

Acrylic, commonly known by brand names such as Perspex and Plexiglas, is a transparent thermoplastic often used as a lightweight and shatter-resistant alternative to glass. Both Perspex and Plexiglas are high-quality acrylic materials, distinguished mainly by their manufacturers and slight differences in clarity or UV resistance. Acrylic's durability, versatility, and excellent optical properties make it ideal for applications in signage, glazing, and displays.

Origin and Brand History: Perspex vs Plexiglas

Perspex, developed in the United Kingdom by ICI (Imperial Chemical Industries) in 1933, was one of the first acrylic products introduced for commercial use. Plexiglas, trademarked by the German chemical company Rohm and Haas in 1936, gained prominence in Europe and North America as a leading acrylic glass brand. Both brands pioneered the acrylic industry, but Perspex is often associated with British manufacturing while Plexiglas is linked to German innovation in polymer science.

Chemical Composition and Properties Comparison

Perspex and Plexiglas are both trade names for polymethyl methacrylate (PMMA), a transparent thermoplastic commonly used as a lightweight alternative to glass. Perspex typically contains UV stabilizers, enhancing its resistance to yellowing and maintaining optical clarity over time, whereas Plexiglas often features superior impact resistance due to balanced molecular weight distribution. Both materials exhibit high light transmission around 92%, excellent weatherability, and chemical resistance, but slight formulation differences influence their durability and flexibility in various industrial applications.

Manufacturing Processes of Perspex and Plexiglas

Perspex and Plexiglas are both types of acrylic created through polymerization, but Perspex typically undergoes bulk polymerization, resulting in solid acrylic sheets with high optical clarity and strength. Plexiglas is often produced via a suspension polymerization process, allowing for better control of molecular weight and offering enhanced impact resistance and flexibility. These distinct manufacturing methods contribute to the variations in mechanical properties and applications of Perspex and Plexiglas in industries like automotive, signage, and construction.

Clarity and Optical Performance Differences

Perspex and Plexiglas are both premium acrylic sheets known for exceptional clarity and optical performance. Perspex typically offers superior light transmission at around 92%, minimizing distortion and providing a crystal-clear finish ideal for display applications. Plexiglas also delivers high transparency but may exhibit slight variations in color neutrality and gloss depending on the specific formulation used.

Strength, Durability, and Weather Resistance

Perspex and Plexiglas are both high-quality acrylic materials known for impressive strength and durability, with Plexiglas often exhibiting slightly higher impact resistance due to its manufacturing process. Both materials demonstrate excellent weather resistance, maintaining clarity and structural integrity under prolonged exposure to UV rays, moisture, and temperature variations. Perspex is widely favored in applications requiring custom fabrication and superior optical clarity, while Plexiglas is commonly used for outdoor installations and protective barriers because of its robust weather-resistant properties.

Common Applications and Uses

Perspex and Plexiglas are both popular acrylic brands widely used in signage, display cases, and glazing due to their clarity and durability. Perspex is often preferred for artistic applications and custom furniture, while Plexiglas finds frequent use in automotive parts, windows, and protective barriers. Both materials are favored in construction and retail for lightweight, impact-resistant alternatives to glass.

Price and Availability Comparison

Perspex and Plexiglas, both popular acrylic brands, differ notably in price and availability, with Plexiglas typically priced higher due to its premium branding and broader distribution network. Perspex is widely accessible in bulk for cost-sensitive projects, often favored by manufacturers needing large acrylic sheets at a competitive price. Availability varies regionally, but Perspex generally offers better stock levels in European markets, while Plexiglas commands stronger presence in North American retail and niche specialty applications.

Which One to Choose: Perspex or Plexiglas?

Perspex and Plexiglas are both popular acrylic brands known for their clarity, durability, and versatility, but Perspex offers slightly better UV resistance, making it ideal for outdoor applications. Plexiglas typically has a smoother surface finish and better impact strength, suitable for protective barriers and signage. Choosing between Perspex and Plexiglas depends on whether weather resistance or surface quality and toughness are the primary project requirements.

Perspex vs Plexiglas Infographic

materialdif.com

materialdif.com