Acrylic sheets offer a flat, smooth surface ideal for glazing, displays, and signage, whereas acrylic rods provide a solid, cylindrical form suited for structural, artistic, and mechanical applications. The choice between acrylic sheet and rod depends on the specific project requirements, such as shape, strength, and visual impact. Both materials share excellent clarity, weather resistance, and ease of fabrication, making them versatile solutions in various industries.

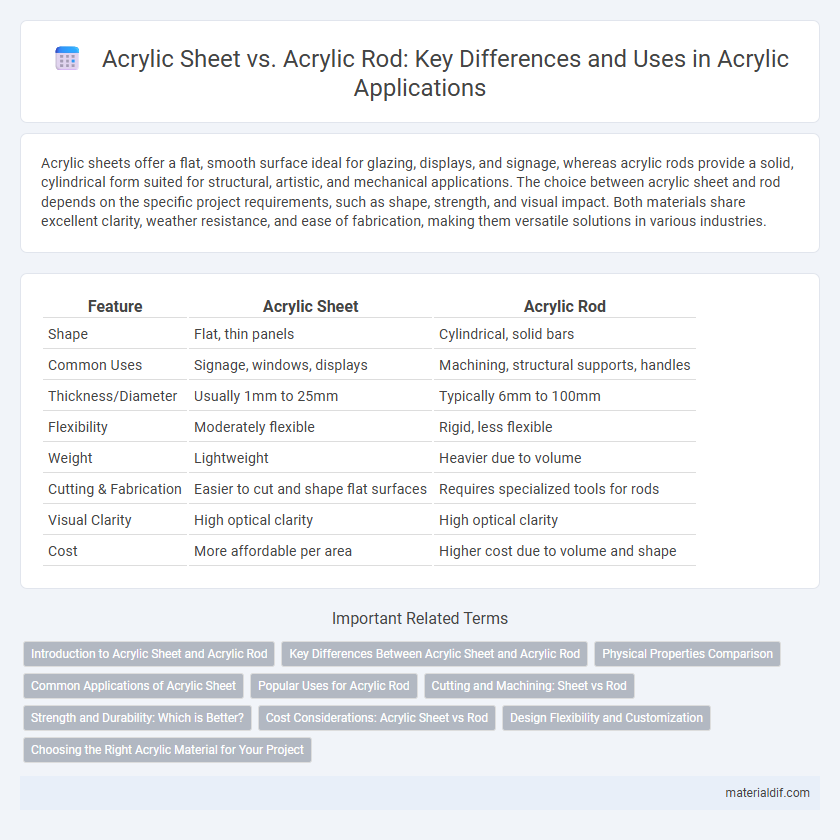

Table of Comparison

| Feature | Acrylic Sheet | Acrylic Rod |

|---|---|---|

| Shape | Flat, thin panels | Cylindrical, solid bars |

| Common Uses | Signage, windows, displays | Machining, structural supports, handles |

| Thickness/Diameter | Usually 1mm to 25mm | Typically 6mm to 100mm |

| Flexibility | Moderately flexible | Rigid, less flexible |

| Weight | Lightweight | Heavier due to volume |

| Cutting & Fabrication | Easier to cut and shape flat surfaces | Requires specialized tools for rods |

| Visual Clarity | High optical clarity | High optical clarity |

| Cost | More affordable per area | Higher cost due to volume and shape |

Introduction to Acrylic Sheet and Acrylic Rod

Acrylic sheets are flat, transparent panels commonly used for glazing, signage, and displays due to their lightweight and shatter-resistant properties. Acrylic rods are solid, cylindrical pieces ideal for structural applications, decorative elements, and machining into custom shapes. Both variants offer excellent clarity, UV resistance, and impact strength, making them versatile materials in construction and manufacturing.

Key Differences Between Acrylic Sheet and Acrylic Rod

Acrylic sheets offer a flat, smooth surface ideal for applications such as glazing, signage, and protective barriers, while acrylic rods provide a cylindrical form used in structural supports, decorative elements, and machining projects. The thickness and shape variations of acrylic sheets make them suitable for large panel covers, whereas acrylic rods are valued for their strength and rotational symmetry in mechanical parts. Transparency, impact resistance, and ease of fabrication differ between sheets and rods, influencing their selection based on project-specific mechanical and aesthetic requirements.

Physical Properties Comparison

Acrylic sheets and acrylic rods differ significantly in physical properties, with sheets offering high impact resistance, excellent clarity, and smooth flat surfaces ideal for glazing and signage. Acrylic rods provide strength and durability with high tensile strength and rigidity, suited for structural applications and machining into custom shapes. Both materials share UV resistance and weatherability but vary in form factor, thickness, and mechanical performance tailored to specific industrial uses.

Common Applications of Acrylic Sheet

Acrylic sheet is widely used for applications such as signage, display cases, and protective barriers due to its excellent clarity, impact resistance, and ease of fabrication. It serves as a preferred material in architecture for windows, skylights, and light diffusers because of its UV resistance and weather durability. In contrast to acrylic rods, sheets provide a versatile flat surface suitable for painting, printing, and lamination in various commercial and industrial settings.

Popular Uses for Acrylic Rod

Acrylic rods are widely used in applications requiring precision and durability, such as in decorative displays, lighting fixtures, and custom furniture components. Their cylindrical shape makes them ideal for turned or machined parts, including handles, standoffs, and spacers. Compared to acrylic sheets, rods offer enhanced strength and versatility in structural and artistic projects.

Cutting and Machining: Sheet vs Rod

Acrylic sheets offer a flat, uniform surface ideal for precision cutting with saws, lasers, or CNC machines, making them suitable for applications requiring sharp, clean edges and intricate shapes. In contrast, acrylic rods require specialized rotary cutting and lathe machining to achieve smooth finishes and precise diameters, often used in cylindrical or rounded components. Both forms demand proper cooling and feed rates during machining to prevent melting or cracking, but sheets typically allow for easier, more versatile fabrication processes compared to rods.

Strength and Durability: Which is Better?

Acrylic sheets and acrylic rods both offer impressive strength and durability, but their performance varies with application. Acrylic sheets provide excellent impact resistance and are less prone to cracking under pressure, making them ideal for large, flat surfaces requiring structural integrity. Acrylic rods, while strong, are more flexible and better suited for applications needing tensile strength and flexibility rather than rigid durability.

Cost Considerations: Acrylic Sheet vs Rod

Acrylic sheets typically cost less per square foot compared to acrylic rods due to their flat form and ease of mass production. Acrylic rods, being cylindrical and requiring more material and complex manufacturing, often come at a higher price point per linear foot. Budget planning for projects involving acrylic should account for these cost differences, balancing material shape requirements with financial constraints.

Design Flexibility and Customization

Acrylic sheets offer superior design flexibility with their broad surface area, allowing for easy cutting, shaping, and engraving to fit various architectural and display applications. Acrylic rods provide customization options through their solid, cylindrical form, making them ideal for supporting structures, decorative accents, and lighting enhancements. Both materials cater to tailored design needs, but sheets excel in flat, expansive projects while rods are preferred for three-dimensional, structural elements.

Choosing the Right Acrylic Material for Your Project

Acrylic sheets provide a flat, versatile surface ideal for applications such as glazing, signage, and displays, offering excellent clarity and ease of cutting or shaping. Acrylic rods, with their cylindrical form, are suited for structural components, decorative elements, and custom machining projects requiring strength and durability. Selecting between acrylic sheet and rod depends on the project's design requirements, whether a broad, flat panel or a solid, rounded piece is needed for optimal performance and aesthetics.

Acrylic Sheet vs Acrylic Rod Infographic

materialdif.com

materialdif.com