Acrylic thickness directly influences its strength and durability, with thicker sheets providing greater impact resistance and load-bearing capacity. Thicker acrylic offers enhanced rigidity, reducing the risk of bending or cracking under pressure, making it ideal for structural applications. Selecting the appropriate thickness balances strength requirements with weight and cost considerations for optimal performance.

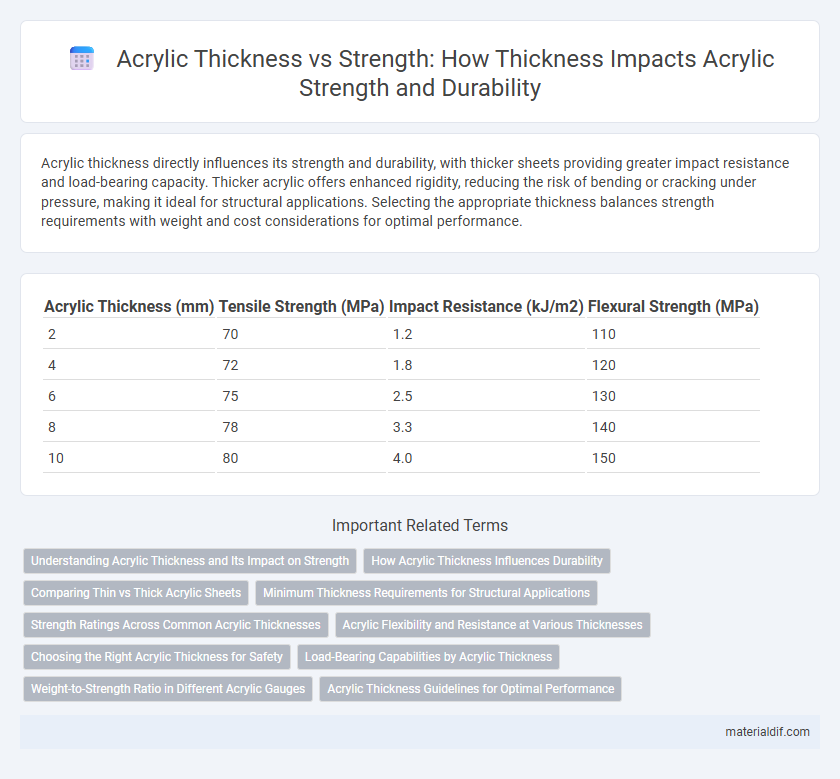

Table of Comparison

| Acrylic Thickness (mm) | Tensile Strength (MPa) | Impact Resistance (kJ/m2) | Flexural Strength (MPa) |

|---|---|---|---|

| 2 | 70 | 1.2 | 110 |

| 4 | 72 | 1.8 | 120 |

| 6 | 75 | 2.5 | 130 |

| 8 | 78 | 3.3 | 140 |

| 10 | 80 | 4.0 | 150 |

Understanding Acrylic Thickness and Its Impact on Strength

Acrylic thickness directly influences its strength, with thicker sheets exhibiting greater resistance to impact and bending. Common thicknesses range from 2mm to 25mm, where increased thickness improves durability and load-bearing capacity. Selecting the appropriate acrylic thickness ensures optimal performance for applications requiring enhanced structural integrity.

How Acrylic Thickness Influences Durability

Acrylic thickness directly influences durability by enhancing its resistance to impact and reducing the likelihood of cracking or breaking under stress. Thicker acrylic sheets distribute force more effectively, increasing their strength and longevity in demanding applications such as glazing or protective barriers. Higher thickness levels also improve the material's ability to withstand environmental factors like wind pressure and UV exposure, extending the life span of acrylic installations.

Comparing Thin vs Thick Acrylic Sheets

Thin acrylic sheets typically offer flexibility and are suitable for lightweight applications but exhibit lower impact resistance and strength compared to thick acrylic sheets. Thick acrylic sheets provide enhanced durability, superior load-bearing capacity, and better resistance to cracking, making them ideal for structural uses. Choosing between thin and thick acrylic depends on balancing desired strength with weight and flexibility requirements.

Minimum Thickness Requirements for Structural Applications

Acrylic thickness directly influences its strength, making minimum thickness requirements crucial for structural applications to ensure safety and durability. Structural guidelines often specify a minimum acrylic thickness of 6 mm for moderate loads, with thicker panels needed for higher stress conditions or larger spans. Adhering to these requirements prevents deformation and maintains load-bearing capacity, optimizing acrylic's performance in glazing, protective barriers, or load-bearing components.

Strength Ratings Across Common Acrylic Thicknesses

Acrylic strength varies significantly with thickness, with standard sheets ranging from 1/8 inch to 1 inch exhibiting tensile strengths between 7,000 and 11,000 psi. Thicker acrylic panels, such as those 1/2 inch and above, generally demonstrate enhanced impact resistance and load-bearing capacity, making them suitable for structural applications. Manufacturers often rate acrylic strength based on standardized tests like ASTM D638, ensuring reliable performance across varying thicknesses for specific industrial and commercial uses.

Acrylic Flexibility and Resistance at Various Thicknesses

Acrylic thickness directly influences its strength, flexibility, and resistance, with thicker sheets offering enhanced impact resistance and rigidity while maintaining moderate flexibility. Thin acrylic panels exhibit greater flexibility, making them suitable for applications requiring bending without cracking, whereas thicker panels provide superior durability and resistance to deformation. Optimal thickness selection balances the need for flexibility and strength, crucial in industries such as automotive glazing, signage, and protective barriers.

Choosing the Right Acrylic Thickness for Safety

Acrylic thickness directly influences the material's strength and impact resistance, making it crucial to select the appropriate gauge for safety-critical applications. Thicker acrylic sheets, typically starting from 6mm, offer enhanced durability and are less prone to cracking or breaking under pressure, ideal for protective barriers and glazing. Ensuring the correct acrylic thickness based on load requirements and exposure conditions maximizes safety and longevity while maintaining clarity and performance.

Load-Bearing Capabilities by Acrylic Thickness

Acrylic thickness directly impacts its load-bearing capabilities, with increased thickness enhancing strength and resistance to bending under stress. Standard acrylic sheets range from 1/8 inch to 1 inch, where thickness increments improve performance in structural applications. For optimal load distribution, thicker acrylic panels provide superior durability and support in both static and dynamic load conditions.

Weight-to-Strength Ratio in Different Acrylic Gauges

Acrylic thickness directly influences its strength, with thicker acrylic sheets offering increased load-bearing capacity and impact resistance. The weight-to-strength ratio varies across different acrylic gauges, where thinner acrylic maintains a favorable balance of lightweight properties while providing sufficient durability for many applications. Selecting the optimal gauge depends on the specific structural requirements, balancing the acrylic's weight efficiency against its mechanical performance.

Acrylic Thickness Guidelines for Optimal Performance

Acrylic thickness directly influences its strength, with thicker sheets offering enhanced durability and resistance to impact. For optimal performance, applications such as protective barriers typically require a minimum thickness of 1/4 inch, while load-bearing uses may necessitate 1/2 inch or more. Selecting the correct acrylic thickness ensures structural integrity and longevity, preventing stress fractures and deformation under pressure.

Acrylic Thickness vs Strength Infographic

materialdif.com

materialdif.com