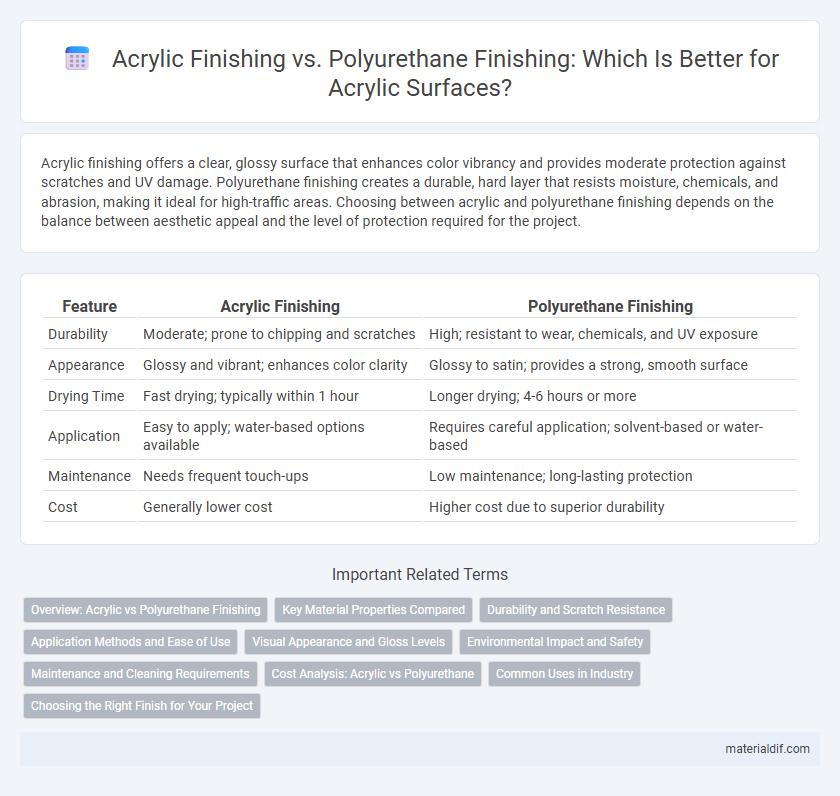

Acrylic finishing offers a clear, glossy surface that enhances color vibrancy and provides moderate protection against scratches and UV damage. Polyurethane finishing creates a durable, hard layer that resists moisture, chemicals, and abrasion, making it ideal for high-traffic areas. Choosing between acrylic and polyurethane finishing depends on the balance between aesthetic appeal and the level of protection required for the project.

Table of Comparison

| Feature | Acrylic Finishing | Polyurethane Finishing |

|---|---|---|

| Durability | Moderate; prone to chipping and scratches | High; resistant to wear, chemicals, and UV exposure |

| Appearance | Glossy and vibrant; enhances color clarity | Glossy to satin; provides a strong, smooth surface |

| Drying Time | Fast drying; typically within 1 hour | Longer drying; 4-6 hours or more |

| Application | Easy to apply; water-based options available | Requires careful application; solvent-based or water-based |

| Maintenance | Needs frequent touch-ups | Low maintenance; long-lasting protection |

| Cost | Generally lower cost | Higher cost due to superior durability |

Overview: Acrylic vs Polyurethane Finishing

Acrylic finishing offers a water-based, fast-drying solution that enhances color vibrancy and provides a clear, non-yellowing coat ideal for indoor projects. Polyurethane finishing, available in oil- and water-based formulas, delivers superior durability and resistance to scratches and chemicals, making it suitable for high-traffic areas and outdoor applications. Both finishes vary in gloss levels and maintenance requirements, with acrylic excelling in ease of use and polyurethane preferred for long-lasting protection.

Key Material Properties Compared

Acrylic finishing offers excellent UV resistance and clarity, making it ideal for projects requiring color retention and a glossy appearance. Polyurethane finishing provides superior durability and abrasion resistance, suited for high-traffic surfaces and enhanced protection against chemicals. Both materials differ in drying times and flexibility, with acrylic drying faster but polyurethane delivering a tougher, more long-lasting finish.

Durability and Scratch Resistance

Acrylic finishing offers moderate durability and scratch resistance, making it suitable for surfaces with minimal wear. Polyurethane finishing provides superior durability and enhanced scratch resistance due to its robust, protective coating, ideal for high-traffic areas and furniture. Choosing polyurethane finishing ensures longer-lasting protection against abrasions compared to acrylic.

Application Methods and Ease of Use

Acrylic finishing typically involves water-based applications that dry quickly and offer easy cleanup with soap and water, making it user-friendly for DIY projects. Polyurethane finishing, available in oil-based and water-based formulas, requires careful application with brushes or sprayers and longer drying times, demanding more skill for smooth, durable results. Acrylic finishes provide straightforward brush or roller use with minimal odor, while polyurethane often needs multiple thin coats and light sanding between layers for optimal durability.

Visual Appearance and Gloss Levels

Acrylic finishing offers a clear, vibrant look with excellent color retention and high-gloss levels that enhance natural wood grain, making it ideal for decorative surfaces. Polyurethane finishing provides a durable, glossy to satin finish, offering superior resistance to scratches and chemicals while slightly deepening the wood's color. Both finishes deliver smooth, glossy aesthetics, but acrylic emphasizes clarity and brightness, whereas polyurethane focuses on durability and depth of gloss.

Environmental Impact and Safety

Acrylic finishing is known for its lower environmental impact due to its water-based composition, producing fewer volatile organic compounds (VOCs) compared to polyurethane finishes. Polyurethane finishing releases higher levels of VOCs and hazardous chemicals, posing greater health risks during application and curing. Choosing acrylic finishes enhances indoor air quality and reduces environmental pollution, making it a safer option for both users and the ecosystem.

Maintenance and Cleaning Requirements

Acrylic finishing requires minimal maintenance, needing only gentle cleaning with soap and water to prevent surface dullness, whereas polyurethane finishing demands more frequent upkeep to maintain its protective layer against scratches and moisture. Acrylic surfaces resist yellowing and can be refreshed with light sanding, while polyurethane may require reapplication over time to restore its durability. Proper cleaning routines for acrylic avoid harsh chemicals that can damage the finish, contrasting with polyurethane which tolerates stronger cleaners but is more prone to wear without regular maintenance.

Cost Analysis: Acrylic vs Polyurethane

Acrylic finishing typically costs less per gallon compared to polyurethane, making it a more budget-friendly option for projects requiring quick drying and ease of application. Polyurethane finishes, though higher in upfront costs, provide greater durability and longer-lasting protection, potentially reducing the need for frequent reapplications over time. When evaluating total expenditure, acrylic may save money initially, but polyurethane's longevity often results in a lower cost per year of coverage.

Common Uses in Industry

Acrylic finishing is commonly used in industries requiring fast-drying and UV-resistant coatings, such as automotive and furniture manufacturing, due to its clarity and flexibility. Polyurethane finishing dominates sectors needing durable, abrasion-resistant surfaces like flooring, cabinetry, and industrial equipment, offering enhanced chemical and impact resistance. Both finishes serve critical roles where specific performance attributes like moisture protection or gloss retention are paramount.

Choosing the Right Finish for Your Project

Acrylic finishing offers a fast-drying, water-based solution that provides a clear, UV-resistant coat ideal for indoor projects requiring a non-yellowing finish. Polyurethane finishing, available in oil- or water-based formulas, delivers a durable, chemical-resistant surface suited for high-traffic areas and outdoor use, with oil-based variants enhancing wood richness but yellowing over time. Selecting the right finish depends on project environment, desired appearance, and durability needs, where acrylic excels in clarity and ease of use while polyurethane prioritizes toughness and longevity.

Acrylic Finishing vs Polyurethane Finishing Infographic

materialdif.com

materialdif.com