Cast acrylic offers superior optical clarity, higher chemical resistance, and better scratch resistance compared to extruded acrylic, making it ideal for high-quality displays and lenses. Extruded acrylic is more cost-effective and easier to fabricate due to its consistent thickness and softer material properties. Choosing between cast and extruded acrylic depends on the specific application requirements, balancing performance, durability, and budget constraints.

Table of Comparison

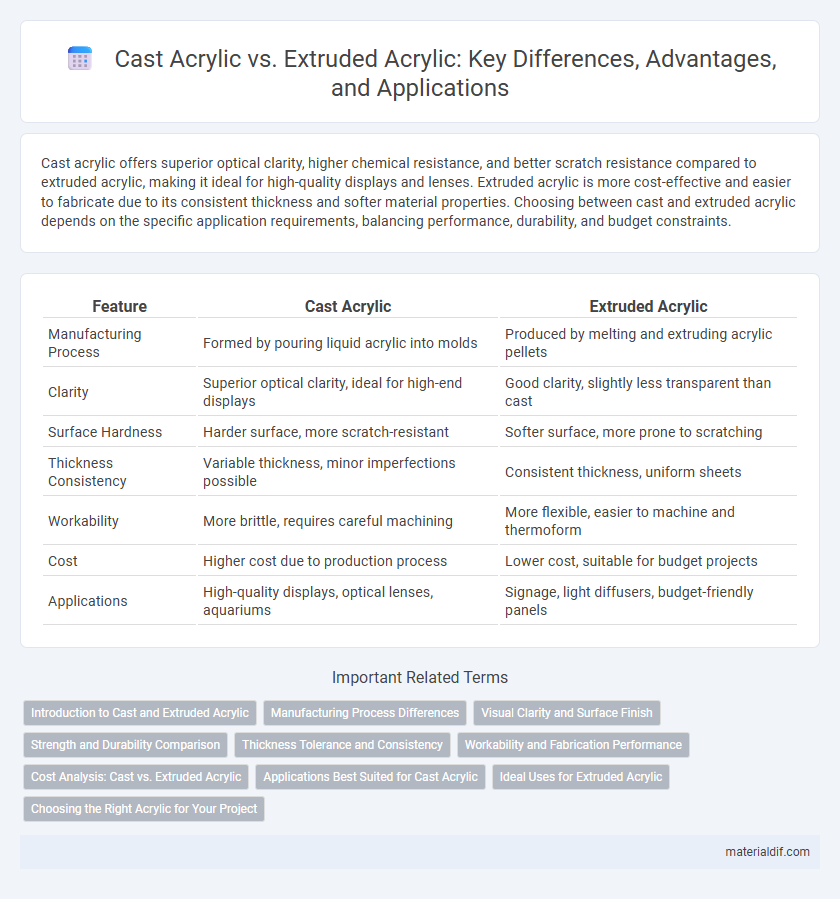

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing Process | Formed by pouring liquid acrylic into molds | Produced by melting and extruding acrylic pellets |

| Clarity | Superior optical clarity, ideal for high-end displays | Good clarity, slightly less transparent than cast |

| Surface Hardness | Harder surface, more scratch-resistant | Softer surface, more prone to scratching |

| Thickness Consistency | Variable thickness, minor imperfections possible | Consistent thickness, uniform sheets |

| Workability | More brittle, requires careful machining | More flexible, easier to machine and thermoform |

| Cost | Higher cost due to production process | Lower cost, suitable for budget projects |

| Applications | High-quality displays, optical lenses, aquariums | Signage, light diffusers, budget-friendly panels |

Introduction to Cast and Extruded Acrylic

Cast acrylic is produced by pouring liquid acrylic into molds, resulting in thicker sheets with superior optical clarity and enhanced chemical resistance, making it ideal for applications requiring high durability. Extruded acrylic is created through a continuous manufacturing process, yielding thinner, more affordable sheets with consistent thickness, suitable for cost-effective projects with moderate strength needs. Both materials offer excellent weather resistance and versatility but differ significantly in manufacturing methods and performance characteristics.

Manufacturing Process Differences

Cast acrylic is produced by pouring liquid acrylic monomer into molds where it polymerizes and cures, resulting in a denser and more chemically resistant material with superior optical clarity. Extruded acrylic is made by forcing melted acrylic through a die, creating continuous sheets with consistent thickness but slightly lower optical purity and chemical resistance. The casting process allows for more customization in thickness and shape, while extrusion enables faster, more cost-effective production of large-volume acrylic sheets.

Visual Clarity and Surface Finish

Cast acrylic offers superior visual clarity and a smoother, more polished surface finish compared to extruded acrylic, making it ideal for high-end displays and optical applications. The manufacturing process of cast acrylic results in fewer impurities and internal stresses, enhancing transparency and gloss. Extruded acrylic, while more affordable and easier to produce in large sheets, tends to have slightly lower clarity and a less refined surface texture.

Strength and Durability Comparison

Cast acrylic exhibits superior strength and durability compared to extruded acrylic due to its higher molecular weight and enhanced resistance to impact and weathering. Its manufacturing process results in a more rigid and scratch-resistant material, making it ideal for demanding applications like automotive parts and outdoor signage. Extruded acrylic tends to be less brittle but offers lower mechanical strength, limiting its use to less critical, indoor applications.

Thickness Tolerance and Consistency

Cast acrylic offers superior thickness tolerance, typically maintaining variations within +-0.005 inches, making it ideal for projects demanding precision and uniformity. Extruded acrylic often exhibits less consistent thickness, with tolerances around +-0.010 inches, which may lead to slight dimensional discrepancies in large-scale or detailed applications. This distinction ensures cast acrylic is preferred where exact measurements and consistent clarity are critical.

Workability and Fabrication Performance

Cast acrylic offers superior workability due to its denser molecular structure, allowing for cleaner cuts, superior edge finishing, and better tolerance to thermoforming and CNC machining compared to extruded acrylic. Extruded acrylic, while more cost-effective, tends to melt and deform more easily during high-heat fabrication processes, leading to limitations in precision and post-processing quality. Choosing cast acrylic enhances fabrication performance in applications demanding high durability, intricate design, and polished aesthetic finishes.

Cost Analysis: Cast vs. Extruded Acrylic

Cast acrylic typically costs more than extruded acrylic due to its superior optical clarity and enhanced chemical resistance, making it ideal for high-precision applications. Extruded acrylic offers a more budget-friendly option with faster production times but may sacrifice some durability and surface quality. Evaluating cost efficiency depends on project requirements, balancing upfront material costs with long-term performance needs.

Applications Best Suited for Cast Acrylic

Cast acrylic is ideal for applications requiring superior optical clarity, enhanced durability, and excellent resistance to environmental stress, such as in high-end display cases, aquariums, and retail signage. Its molecular structure offers greater chemical resistance and better machinability, making it suitable for intricate designs and laser cutting tasks. Cast acrylic's superior thickness uniformity and high-gloss finish are preferred in medical devices, automotive parts, and architectural glazing.

Ideal Uses for Extruded Acrylic

Extruded acrylic is ideal for applications requiring easier fabrication and shaping due to its softer, more flexible nature compared to cast acrylic. It is commonly used in signage, displays, and protective barriers where cost-effectiveness and consistent sheet thickness are important. Its superior workability makes it preferred for projects involving bending, thermoforming, or extensive machining.

Choosing the Right Acrylic for Your Project

Cast acrylic offers superior strength, clarity, and chemical resistance, making it ideal for high-quality displays and applications requiring precision machining. Extruded acrylic is more affordable and easier to fabricate, suitable for large panels and general-purpose uses where cost efficiency is a priority. Selecting the right acrylic depends on project requirements such as durability, surface finish, and budget constraints.

Cast Acrylic vs Extruded Acrylic Infographic

materialdif.com

materialdif.com