Acrylic panels offer superior optical clarity and scratch resistance compared to Lexan panels, making them ideal for display cases and windows where visual quality is paramount. Lexan panels provide greater impact resistance and durability, often preferred in safety glazing and protective barriers. Choosing between acrylic and Lexan panels depends on prioritizing either clarity and scratch resistance or toughness and impact strength.

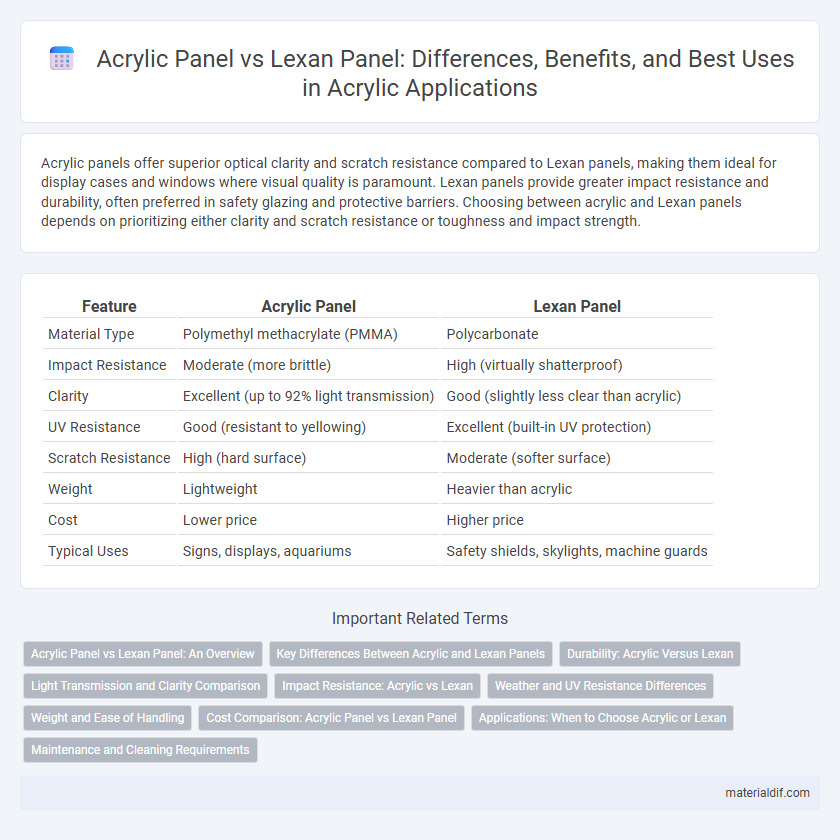

Table of Comparison

| Feature | Acrylic Panel | Lexan Panel |

|---|---|---|

| Material Type | Polymethyl methacrylate (PMMA) | Polycarbonate |

| Impact Resistance | Moderate (more brittle) | High (virtually shatterproof) |

| Clarity | Excellent (up to 92% light transmission) | Good (slightly less clear than acrylic) |

| UV Resistance | Good (resistant to yellowing) | Excellent (built-in UV protection) |

| Scratch Resistance | High (hard surface) | Moderate (softer surface) |

| Weight | Lightweight | Heavier than acrylic |

| Cost | Lower price | Higher price |

| Typical Uses | Signs, displays, aquariums | Safety shields, skylights, machine guards |

Acrylic Panel vs Lexan Panel: An Overview

Acrylic panels offer superior optical clarity and weather resistance compared to Lexan panels, making them ideal for applications requiring high transparency and UV stability. Lexan panels, a type of polycarbonate, deliver greater impact resistance and flexibility but may yellow over time under prolonged sun exposure. Choosing between acrylic and Lexan panels depends on balancing factors such as durability, clarity, UV resistance, and cost for specific project needs.

Key Differences Between Acrylic and Lexan Panels

Acrylic panels offer superior optical clarity and scratch resistance, making them ideal for display cases and signage, while Lexan panels provide enhanced impact resistance and durability, often used in safety or security applications. Acrylic is more rigid but prone to cracking under high stress, whereas Lexan is more flexible and less likely to shatter, suitable for environments requiring impact resistance. Both materials are lightweight and weather-resistant, but their distinct mechanical properties determine their best use cases.

Durability: Acrylic Versus Lexan

Acrylic panels offer strong resistance to UV light and weathering but can be more prone to cracking and scratching compared to Lexan panels. Lexan, a brand of polycarbonate, exhibits superior impact resistance, making it virtually shatterproof and ideal for high-durability applications. While acrylic is more rigid and offers better optical clarity, Lexan's toughness and flexibility make it the preferred choice for environments requiring high durability and impact resistance.

Light Transmission and Clarity Comparison

Acrylic panels offer superior light transmission rates, typically around 92%, providing exceptional clarity and brightness compared to Lexan panels, which usually have light transmission rates near 88%. The enhanced optical clarity of acrylic makes it ideal for applications demanding high transparency and minimal distortion, such as display cases and glazing. Although Lexan panels are more impact-resistant, acrylic's clearer visibility remains preferable for aesthetic and visual performance needs.

Impact Resistance: Acrylic vs Lexan

Lexan panels exhibit significantly higher impact resistance compared to acrylic panels, making them ideal for applications requiring enhanced durability and safety. Acrylic panels tend to be more brittle and prone to cracking under strong impact, whereas Lexan, a polycarbonate material, can absorb and withstand substantial force without breaking. This superior toughness makes Lexan a preferred choice in environments exposed to physical stress or potential vandalism.

Weather and UV Resistance Differences

Acrylic panels offer superior UV resistance, maintaining clarity and color without yellowing for over 10 years, making them ideal for outdoor applications exposed to sunlight. Lexan panels, while highly impact-resistant and more flexible, tend to degrade faster under prolonged UV exposure if not treated with special coatings, leading to discoloration and brittleness within 3 to 5 years. Weather resistance in acrylic panels includes excellent resistance to rain, wind, and temperature fluctuations, whereas untreated Lexan may require additional UV protective layers to match this durability.

Weight and Ease of Handling

Acrylic panels weigh approximately 30-50% less than Lexan (polycarbonate) panels, making them significantly easier to handle and install in various applications. The lighter weight of acrylic contributes to reduced labor costs and quicker installation times, especially in large-scale projects such as signage and display cases. Acrylic's rigidity and lower density provide a balance of durability and manageability compared to the heavier and more flexible Lexan alternatives.

Cost Comparison: Acrylic Panel vs Lexan Panel

Acrylic panels typically cost less than Lexan panels, making them a budget-friendly option for many applications. While Lexan panels come with a higher price tag, their superior impact resistance and durability can justify the investment for demanding environments. Choosing between acrylic and Lexan should consider both upfront material costs and long-term value based on performance requirements.

Applications: When to Choose Acrylic or Lexan

Acrylic panels excel in applications requiring superior optical clarity, UV resistance, and scratch resistance, making them ideal for display cases, signage, and picture frames. Lexan panels, noted for their exceptional impact resistance and thermal stability, are preferred in safety shields, riot barriers, and machine guards where durability and toughness are critical. Selecting between acrylic and Lexan depends on the balance between clarity and strength needs specific to the application environment.

Maintenance and Cleaning Requirements

Acrylic panels require gentle cleaning with mild soap and water to avoid surface scratches, while Lexan panels tolerate more rigorous cleaning methods, including some solvent-based cleaners. Both materials resist UV damage but Lexan's higher scratch resistance reduces the need for frequent maintenance. Regular cleaning prolongs clarity and performance, with acrylic demanding more careful handling to maintain its appearance.

Acrylic Panel vs Lexan Panel Infographic

materialdif.com

materialdif.com