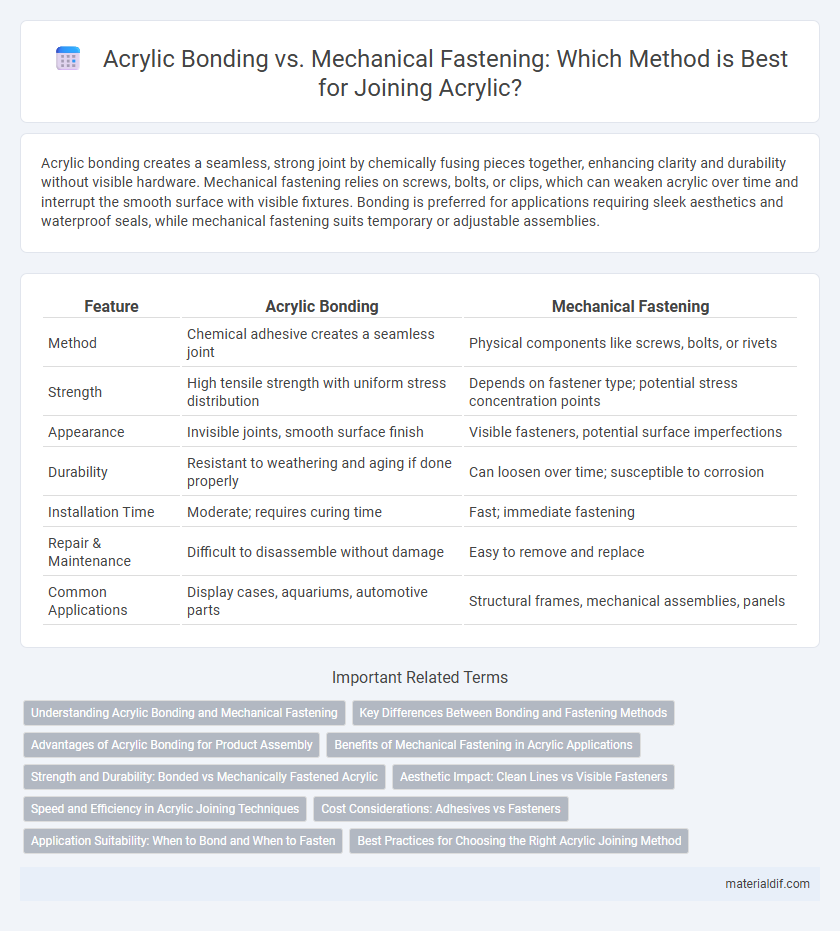

Acrylic bonding creates a seamless, strong joint by chemically fusing pieces together, enhancing clarity and durability without visible hardware. Mechanical fastening relies on screws, bolts, or clips, which can weaken acrylic over time and interrupt the smooth surface with visible fixtures. Bonding is preferred for applications requiring sleek aesthetics and waterproof seals, while mechanical fastening suits temporary or adjustable assemblies.

Table of Comparison

| Feature | Acrylic Bonding | Mechanical Fastening |

|---|---|---|

| Method | Chemical adhesive creates a seamless joint | Physical components like screws, bolts, or rivets |

| Strength | High tensile strength with uniform stress distribution | Depends on fastener type; potential stress concentration points |

| Appearance | Invisible joints, smooth surface finish | Visible fasteners, potential surface imperfections |

| Durability | Resistant to weathering and aging if done properly | Can loosen over time; susceptible to corrosion |

| Installation Time | Moderate; requires curing time | Fast; immediate fastening |

| Repair & Maintenance | Difficult to disassemble without damage | Easy to remove and replace |

| Common Applications | Display cases, aquariums, automotive parts | Structural frames, mechanical assemblies, panels |

Understanding Acrylic Bonding and Mechanical Fastening

Acrylic bonding utilizes chemical adhesives to create strong, seamless joints that enhance clarity and maintain the material's aesthetic appeal, making it ideal for display cases and modern architectural elements. Mechanical fastening involves screws, bolts, or rivets, providing durable hold with the ability for disassembly but potentially compromising acrylic's visual smoothness due to drilled holes. Understanding the balance between the superior visual quality of acrylic bonding and the practical, adjustable nature of mechanical fastening informs optimal construction and design decisions.

Key Differences Between Bonding and Fastening Methods

Acrylic bonding creates a seamless, strong joint by using adhesives that chemically fuse acrylic surfaces, offering superior clarity and stress distribution compared to mechanical fastening. Mechanical fastening relies on screws, bolts, or rivets that physically hold acrylic pieces together but can introduce stress points and cause visible damage or distortion. Bonding provides enhanced aesthetic appeal and durability, while fastening allows for easier disassembly and maintenance.

Advantages of Acrylic Bonding for Product Assembly

Acrylic bonding offers superior clarity and corrosion resistance compared to mechanical fastening, ensuring a seamless and aesthetically pleasing product assembly. Its strong adhesive properties distribute stress evenly, enhancing durability and reducing the risk of material fatigue or failure over time. This method also eliminates the need for drilling or fasteners, preserving material integrity and reducing assembly time and costs.

Benefits of Mechanical Fastening in Acrylic Applications

Mechanical fastening in acrylic applications offers superior strength and reliability by securely joining components without the risk of chemical degradation or weakening caused by adhesives. This method allows for easy disassembly and reassembly, facilitating maintenance, repairs, and modifications while preserving the integrity of acrylic materials. Mechanical fasteners provide consistent performance in dynamic or load-bearing environments, making them ideal for structural and industrial acrylic uses.

Strength and Durability: Bonded vs Mechanically Fastened Acrylic

Acrylic bonding creates a seamless, uniform joint that distributes stress evenly, resulting in superior strength and enhanced durability compared to mechanical fastening methods. Mechanical fasteners, such as screws or rivets, introduce stress concentration points that can weaken the acrylic and increase the risk of cracking or failure under load. The chemical bond formed in acrylic bonding ensures long-term resilience against environmental factors like moisture and temperature fluctuations, making it the preferred choice for applications requiring robust and enduring joints.

Aesthetic Impact: Clean Lines vs Visible Fasteners

Acrylic bonding creates sleek, seamless joints that maintain clean lines and enhance the visual appeal of finished products, making it ideal for applications requiring high aesthetic standards. Mechanical fastening introduces visible screws, bolts, or rivets that can disrupt the smooth surface and detract from the overall design elegance. Choosing acrylic bonding over mechanical fastening ensures unobtrusive connections that preserve the material's clarity and modern look.

Speed and Efficiency in Acrylic Joining Techniques

Acrylic bonding offers superior speed and efficiency compared to mechanical fastening by eliminating the need for drilling holes or using additional hardware. Bonding creates a seamless, strong joint that reduces assembly time and labor costs while maintaining clarity and aesthetic quality. Mechanical fastening can compromise the acrylic's integrity and typically requires more precise alignment and longer processing times.

Cost Considerations: Adhesives vs Fasteners

Acrylic bonding offers cost efficiency through reduced labor and streamlined assembly compared to mechanical fastening, which requires additional components like screws or rivets. Adhesives eliminate the need for pre-drilled holes, minimizing material waste and preserving acrylic's structural integrity, thereby lowering replacement costs. While initial adhesive costs may be higher, the overall savings in production time and maintenance make bonding a more economical choice for acrylic applications.

Application Suitability: When to Bond and When to Fasten

Acrylic bonding is ideal for applications requiring a seamless, transparent finish and strong, uniform stress distribution, such as in display cases and aquariums. Mechanical fastening suits projects needing easy disassembly or enhanced structural support, like in construction frameworks or modular assemblies. Choosing between bonding and fastening depends on factors like load requirements, environmental exposure, and maintenance needs.

Best Practices for Choosing the Right Acrylic Joining Method

Selecting the appropriate acrylic bonding technique depends on factors like load requirements, environmental exposure, and aesthetics; solvent bonding offers seamless joints ideal for clear acrylic displays, while adhesive bonding provides versatility for complex shapes and heavier loads. Mechanical fastening, including screws and rivets, is preferred when disassembly is necessary or when working with thicker acrylic sheets, though it may introduce stress points and visible hardware. Best practices involve assessing application demands, material thickness, and desired durability to optimize joint strength and maintain acrylic integrity.

Acrylic Bonding vs Mechanical Fastening Infographic

materialdif.com

materialdif.com