Acrylic diffusers offer superior clarity and UV resistance compared to polycarbonate diffusers, making them ideal for applications where light quality and durability are critical. Polycarbonate diffusers are more impact-resistant and better suited for environments requiring high toughness and flexibility. Choosing between acrylic and polycarbonate diffusers depends on balancing light diffusion quality with mechanical strength requirements.

Table of Comparison

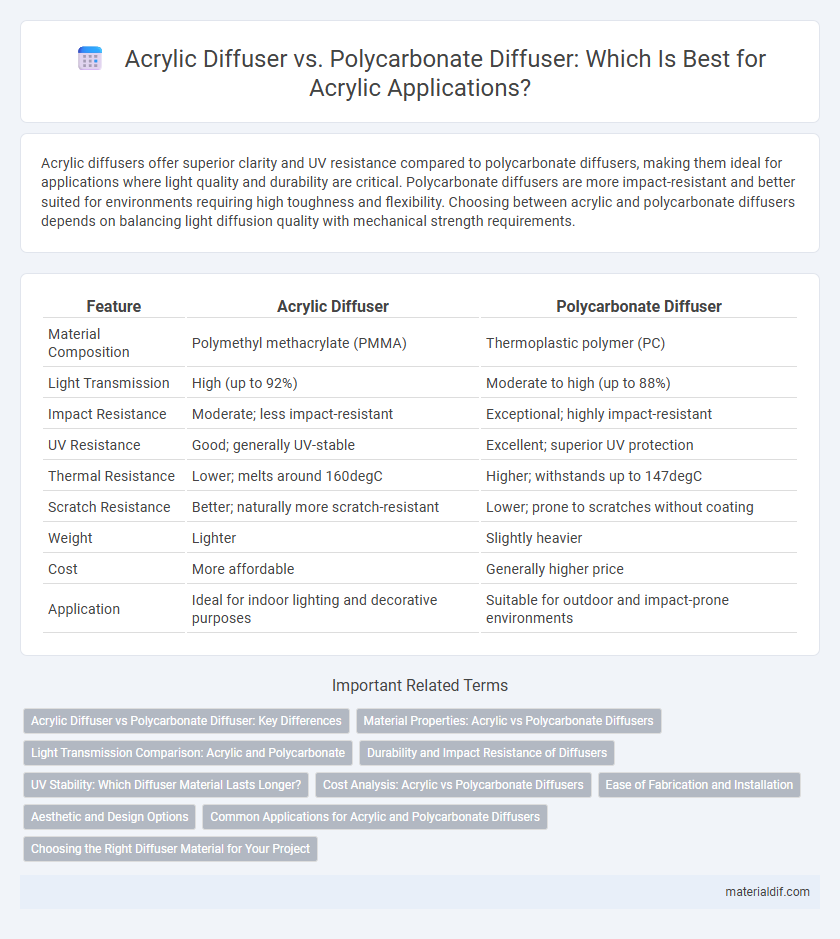

| Feature | Acrylic Diffuser | Polycarbonate Diffuser |

|---|---|---|

| Material Composition | Polymethyl methacrylate (PMMA) | Thermoplastic polymer (PC) |

| Light Transmission | High (up to 92%) | Moderate to high (up to 88%) |

| Impact Resistance | Moderate; less impact-resistant | Exceptional; highly impact-resistant |

| UV Resistance | Good; generally UV-stable | Excellent; superior UV protection |

| Thermal Resistance | Lower; melts around 160degC | Higher; withstands up to 147degC |

| Scratch Resistance | Better; naturally more scratch-resistant | Lower; prone to scratches without coating |

| Weight | Lighter | Slightly heavier |

| Cost | More affordable | Generally higher price |

| Application | Ideal for indoor lighting and decorative purposes | Suitable for outdoor and impact-prone environments |

Acrylic Diffuser vs Polycarbonate Diffuser: Key Differences

Acrylic diffusers offer higher optical clarity and better light transmission, making them ideal for applications requiring bright, uniform lighting. Polycarbonate diffusers provide superior impact resistance and durability, suitable for environments exposed to mechanical stress or harsh conditions. The choice depends on the specific needs for visual performance versus toughness in lighting design.

Material Properties: Acrylic vs Polycarbonate Diffusers

Acrylic diffusers offer excellent optical clarity with a high light transmittance rate of up to 92%, providing uniform light diffusion while maintaining impact resistance suitable for indoor applications. Polycarbonate diffusers surpass acrylic in toughness, featuring superior impact resistance and heat endurance, making them ideal for outdoor or harsh environments where durability is critical. Both materials enable effective light diffusion, but acrylic excels in scratch resistance and color retention, whereas polycarbonate provides enhanced strength and thermal stability.

Light Transmission Comparison: Acrylic and Polycarbonate

Acrylic diffusers typically offer higher light transmission rates, averaging around 92%, compared to polycarbonate diffusers, which generally transmit about 85-90% of light. Acrylic's superior clarity and lower haze levels contribute to more efficient and uniform light diffusion, making it ideal for applications requiring maximum brightness. Polycarbonate diffusers, while slightly less transparent, provide better impact resistance and thermal stability but at the cost of reduced light clarity.

Durability and Impact Resistance of Diffusers

Acrylic diffusers offer excellent clarity and UV resistance but have lower impact resistance compared to polycarbonate diffusers. Polycarbonate diffusers provide superior durability and impact resistance, making them ideal for environments prone to physical stress or vandalism. The enhanced toughness of polycarbonate ensures longer-lasting performance in harsh conditions, whereas acrylic may crack or chip under heavy impact.

UV Stability: Which Diffuser Material Lasts Longer?

Acrylic diffusers offer superior UV stability compared to polycarbonate, making them more resistant to yellowing and degradation over time when exposed to sunlight. Polycarbonate diffusers tend to lose clarity faster due to UV exposure, which can reduce their lifespan in outdoor or high-UV environments. Therefore, acrylic diffusers generally last longer and maintain optical clarity better under prolonged UV radiation.

Cost Analysis: Acrylic vs Polycarbonate Diffusers

Acrylic diffusers typically cost less per square foot compared to polycarbonate diffusers, making them a budget-friendly option for lighting applications. Polycarbonate diffusers offer higher impact resistance and durability but come with a higher upfront cost that may justify long-term savings in harsh environments. When analyzing cost, factors such as material price, lifespan, and maintenance must be weighed to determine the most economical choice for specific project requirements.

Ease of Fabrication and Installation

Acrylic diffusers offer superior ease of fabrication due to their excellent machinability, allowing for precise cutting, drilling, and thermoforming without cracking or chipping. Polycarbonate diffusers, while tougher and more impact-resistant, are harder to machine and require specialized tools to avoid heat buildup that can cause deformation during fabrication. Installation is generally simpler with acrylic diffusers because of their lightweight nature and dimensional stability, reducing handling challenges compared to the heavier and more flexible polycarbonate counterparts.

Aesthetic and Design Options

Acrylic diffusers offer superior clarity and a glossy finish, providing a sleek and modern aesthetic ideal for high-end lighting designs. Polycarbonate diffusers, known for their durability, often have a slightly matte appearance, limiting the range of visual effects but enhancing impact resistance. Designers favor acrylic for vibrant color customization and intricate shaping possibilities, while polycarbonate suits applications prioritizing toughness over refined aesthetics.

Common Applications for Acrylic and Polycarbonate Diffusers

Acrylic diffusers are widely used in indoor lighting fixtures, retail displays, and signage due to their excellent light transmission and scratch resistance. Polycarbonate diffusers find common applications in outdoor lighting, automotive lenses, and industrial equipment because of their superior impact resistance and heat tolerance. Both materials are essential in architectural lighting and electronics where durability and optical clarity are critical.

Choosing the Right Diffuser Material for Your Project

Acrylic diffusers offer superior light transmission and excellent clarity, making them ideal for applications requiring bright, uniform illumination and aesthetic appeal. Polycarbonate diffusers provide enhanced impact resistance and durability, suitable for environments exposed to physical stress or temperature variations. Selecting the right diffuser material depends on balancing optical performance with environmental and mechanical demands specific to your project requirements.

Acrylic Diffuser vs Polycarbonate Diffuser Infographic

materialdif.com

materialdif.com