Acrylic tubes offer superior clarity and scratch resistance compared to polycarbonate tubes, making them ideal for display and decorative applications. Polycarbonate tubes provide greater impact resistance and durability, which is better suited for environments requiring high toughness and safety. Choosing between acrylic and polycarbonate tubes depends on whether optical clarity or impact strength is the priority for the intended use.

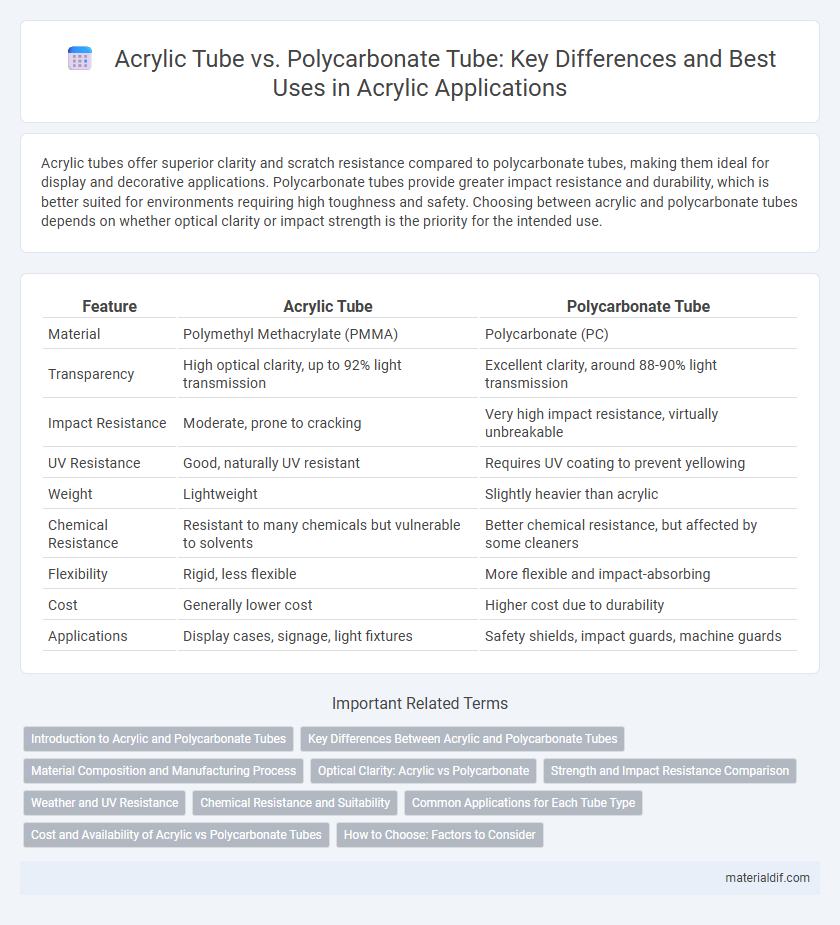

Table of Comparison

| Feature | Acrylic Tube | Polycarbonate Tube |

|---|---|---|

| Material | Polymethyl Methacrylate (PMMA) | Polycarbonate (PC) |

| Transparency | High optical clarity, up to 92% light transmission | Excellent clarity, around 88-90% light transmission |

| Impact Resistance | Moderate, prone to cracking | Very high impact resistance, virtually unbreakable |

| UV Resistance | Good, naturally UV resistant | Requires UV coating to prevent yellowing |

| Weight | Lightweight | Slightly heavier than acrylic |

| Chemical Resistance | Resistant to many chemicals but vulnerable to solvents | Better chemical resistance, but affected by some cleaners |

| Flexibility | Rigid, less flexible | More flexible and impact-absorbing |

| Cost | Generally lower cost | Higher cost due to durability |

| Applications | Display cases, signage, light fixtures | Safety shields, impact guards, machine guards |

Introduction to Acrylic and Polycarbonate Tubes

Acrylic tubes are lightweight, rigid, and offer excellent optical clarity with high UV resistance, making them ideal for display and lighting applications. Polycarbonate tubes provide superior impact resistance and greater heat tolerance, suitable for demanding industrial and safety uses. Both materials serve distinct roles where clarity and durability are critical but vary significantly in strength and environmental performance.

Key Differences Between Acrylic and Polycarbonate Tubes

Acrylic tubes offer superior clarity and scratch resistance, making them ideal for display cases and lighting applications, while polycarbonate tubes provide greater impact resistance and heat tolerance, suitable for industrial and safety uses. Acrylic is less flexible and more prone to cracking under stress, whereas polycarbonate tubes exhibit higher durability and can withstand harsh environments. Cost differences also arise, with acrylic being generally more affordable than polycarbonate, influencing material selection based on budget and application requirements.

Material Composition and Manufacturing Process

Acrylic tubes, composed of polymethyl methacrylate (PMMA), are produced through extrusion or casting processes that yield high optical clarity and UV resistance, making them ideal for applications requiring transparency. Polycarbonate tubes, made from polymerized bisphenol A and phosgene, are typically manufactured via extrusion and injection molding, offering superior impact resistance and thermal stability compared to acrylic. The differing molecular structures and fabrication techniques result in acrylic tubes being more brittle but clearer, while polycarbonate tubes provide enhanced durability and flexibility for industrial use.

Optical Clarity: Acrylic vs Polycarbonate

Acrylic tubes exhibit superior optical clarity compared to polycarbonate tubes, allowing up to 92% light transmission with minimal distortion. Polycarbonate tubes offer good clarity but typically transmit around 88-90% of light, resulting in slightly more visual haze. Acrylic's higher refractive index and lower surface scattering make it ideal for applications requiring crisp, clear visuals.

Strength and Impact Resistance Comparison

Acrylic tubes offer excellent clarity and scratch resistance but have lower impact strength compared to polycarbonate tubes, which provide superior toughness and can withstand higher impact forces without cracking. Polycarbonate tubes are approximately 200 times more impact resistant than acrylic, making them ideal for applications requiring enhanced durability and safety. Despite their strength, polycarbonate tubes may scratch more easily than acrylic, necessitating protective coatings in high-wear environments.

Weather and UV Resistance

Acrylic tubes offer superior weather and UV resistance compared to polycarbonate tubes, maintaining clarity and structural integrity even after prolonged exposure to sunlight and harsh environmental conditions. Polycarbonate tubes tend to yellow and degrade faster under UV radiation, making them less ideal for outdoor applications without additional UV-protective coatings. The enhanced UV stability of acrylic ensures longer-lasting performance in outdoor signage, aquariums, and architectural glazing.

Chemical Resistance and Suitability

Acrylic tubes offer superior chemical resistance against acids and alkalis, making them ideal for applications involving exposure to harsh chemicals. Polycarbonate tubes, while slightly more impact-resistant, are more susceptible to damage from solvents and alcohols, limiting their use in chemically aggressive environments. Acrylic's enhanced durability in chemical exposure ensures longer-lasting performance in laboratory and industrial settings compared to polycarbonate.

Common Applications for Each Tube Type

Acrylic tubes are widely used in applications requiring optical clarity and UV resistance, such as display cases, signage, and aquarium windows, due to their excellent transparency and scratch resistance. Polycarbonate tubes are preferred in impact-resistant and safety-critical environments like protective barriers, machine guards, and bullet-resistant windows because of their superior toughness and high impact strength. Both materials serve distinct purposes, with acrylic excelling in aesthetic and light transmission roles, while polycarbonate meets demands for durability and safety in industrial and protective applications.

Cost and Availability of Acrylic vs Polycarbonate Tubes

Acrylic tubes are generally more cost-effective than polycarbonate tubes, making them a popular choice for budget-conscious projects. Acrylic is widely available in various sizes and thicknesses at most hardware stores and online retailers, ensuring easy access for both small-scale and large-scale needs. Polycarbonate tubes, while more expensive due to their impact resistance and durability, may have limited availability and higher lead times compared to acrylic options.

How to Choose: Factors to Consider

When choosing between acrylic and polycarbonate tubes, consider factors such as impact resistance, clarity, and cost. Acrylic tubes offer superior optical clarity and scratch resistance, making them ideal for display cases or lighting applications, while polycarbonate tubes excel in impact resistance and durability for high-stress environments. Evaluate the specific requirements for strength, transparency, UV resistance, and budget to determine the best material for your project.

Acrylic Tube vs Polycarbonate Tube Infographic

materialdif.com

materialdif.com