Impact-modified acrylic offers enhanced durability and resistance to cracking compared to regular acrylic, making it ideal for applications requiring higher strength. Unlike standard acrylic, impact-modified variants contain additives that improve toughness without compromising clarity or UV resistance. This makes impact-modified acrylic a preferred choice for protective barriers, automotive parts, and outdoor signage where durability is critical.

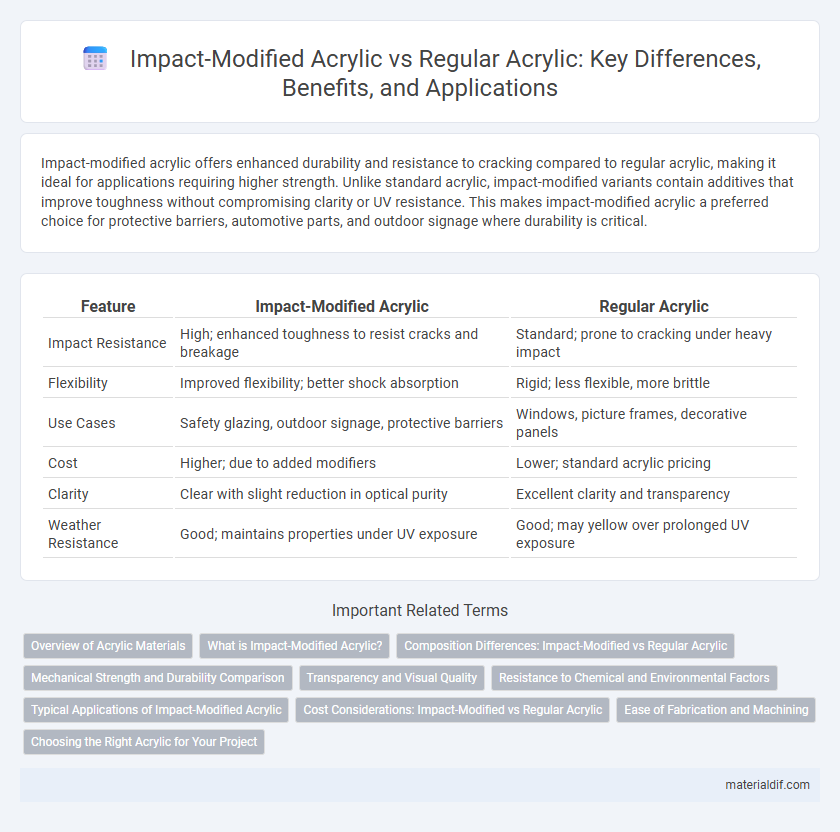

Table of Comparison

| Feature | Impact-Modified Acrylic | Regular Acrylic |

|---|---|---|

| Impact Resistance | High; enhanced toughness to resist cracks and breakage | Standard; prone to cracking under heavy impact |

| Flexibility | Improved flexibility; better shock absorption | Rigid; less flexible, more brittle |

| Use Cases | Safety glazing, outdoor signage, protective barriers | Windows, picture frames, decorative panels |

| Cost | Higher; due to added modifiers | Lower; standard acrylic pricing |

| Clarity | Clear with slight reduction in optical purity | Excellent clarity and transparency |

| Weather Resistance | Good; maintains properties under UV exposure | Good; may yellow over prolonged UV exposure |

Overview of Acrylic Materials

Impact-modified acrylic contains rubber additives that enhance its toughness and resistance to shattering compared to regular acrylic, which is more prone to cracking under stress. Both materials are lightweight, UV-resistant, and offer excellent optical clarity, but impact-modified acrylic is preferred for applications requiring greater durability and safety. Regular acrylic remains popular for aesthetic uses where impact resistance is less critical, due to its cost-effectiveness and ease of fabrication.

What is Impact-Modified Acrylic?

Impact-modified acrylic is a variant of regular acrylic designed to enhance toughness and resistance to cracking by incorporating rubber or other impact-resistant polymers into the acrylic matrix. This modification improves durability, making impact-modified acrylic suitable for applications requiring higher mechanical strength, such as safety windows, lenses, and automotive parts. Regular acrylic, while clear and rigid, lacks this enhanced impact resistance, leading to greater vulnerability under stress or impact.

Composition Differences: Impact-Modified vs Regular Acrylic

Impact-modified acrylic contains rubber or elastomeric additives integrated into the polymer matrix, enhancing toughness and resistance to impact, while regular acrylic is composed primarily of polymethyl methacrylate (PMMA) without these modifiers. The rubber particles in impact-modified acrylic disperse stress more effectively, preventing cracks and fractures under sudden forces, contrasting with the more brittle nature of standard acrylic. Consequently, impact-modified acrylic is favored in applications requiring higher durability, whereas regular acrylic is suited for clarity and rigidity in less demanding environments.

Mechanical Strength and Durability Comparison

Impact-modified acrylic exhibits enhanced mechanical strength, with increased resistance to cracking and breaking under stress compared to regular acrylic. Its improved durability allows it to withstand higher impact forces, making it suitable for applications requiring greater toughness and longer lifespan. Regular acrylic, while clear and rigid, is more prone to shattering under sudden impacts due to lower impact resistance.

Transparency and Visual Quality

Impact-modified acrylic exhibits enhanced durability while maintaining high transparency levels comparable to regular acrylic, with light transmission rates typically above 90%. The addition of modifiers does not significantly compromise visual clarity, ensuring a clear, distortion-free appearance ideal for display and glazing applications. Regular acrylic remains popular for its excellent optical quality, but impact-modified variants offer a superior balance of strength and visual performance in demanding environments.

Resistance to Chemical and Environmental Factors

Impact-modified acrylic exhibits enhanced resistance to environmental stressors, including UV radiation and temperature fluctuations, compared to regular acrylic, making it more durable in outdoor applications. Chemical resistance is also improved due to the presence of impact modifiers that reduce susceptibility to cracking and degradation when exposed to solvents and pollutants. These properties make impact-modified acrylic a superior choice for demanding environments requiring long-lasting clarity and strength.

Typical Applications of Impact-Modified Acrylic

Impact-modified acrylic is commonly used in applications requiring enhanced durability and resistance to impact, such as automotive parts, protective shields, and safety glazing. Its improved toughness makes it ideal for outdoor signage, display cases, and eyewear lenses that must withstand frequent handling and potential impact. Regular acrylic, while clear and lightweight, is best suited for decorative or low-impact uses like picture frames and indoor displays.

Cost Considerations: Impact-Modified vs Regular Acrylic

Impact-modified acrylic generally costs 20-40% more than regular acrylic due to added polymers that enhance durability and resistance to cracking. While regular acrylic offers a lower upfront price, impact-modified acrylic's longer lifespan and reduced maintenance needs often lead to better long-term value. Project budgets should weigh initial material costs against potential savings from fewer replacements and repairs when choosing between these acrylic types.

Ease of Fabrication and Machining

Impact-modified acrylic offers enhanced toughness compared to regular acrylic while maintaining comparable ease of fabrication and machining, allowing for smoother cutting, drilling, and shaping processes. Its improved resistance to cracking under stress reduces breakage during machining, making it ideal for applications requiring durability and precision. Regular acrylic, though easier to machine in delicate, low-stress projects, is more prone to chipping and cracking during fabrication.

Choosing the Right Acrylic for Your Project

Impact-modified acrylic offers enhanced durability and resistance to cracking compared to regular acrylic, making it ideal for high-stress applications such as protective barriers and outdoor signage. Regular acrylic provides excellent clarity and is suitable for decorative or light-duty projects where impact resistance is less critical. Selecting the right acrylic depends on project requirements, balancing factors like strength, clarity, and budget to ensure optimal performance and longevity.

Impact-Modified Acrylic vs Regular Acrylic Infographic

materialdif.com

materialdif.com