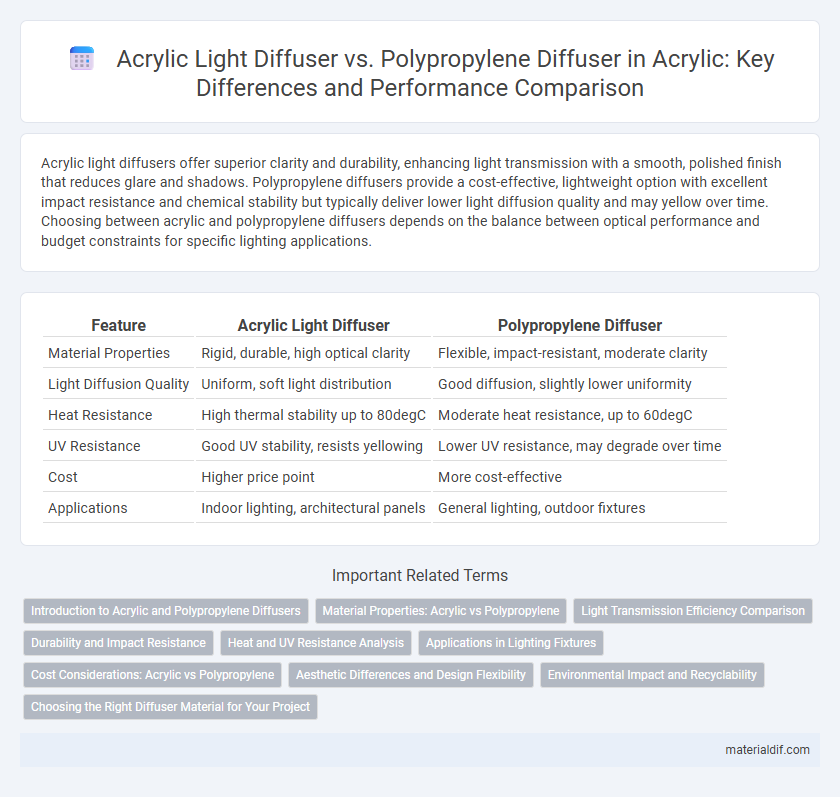

Acrylic light diffusers offer superior clarity and durability, enhancing light transmission with a smooth, polished finish that reduces glare and shadows. Polypropylene diffusers provide a cost-effective, lightweight option with excellent impact resistance and chemical stability but typically deliver lower light diffusion quality and may yellow over time. Choosing between acrylic and polypropylene diffusers depends on the balance between optical performance and budget constraints for specific lighting applications.

Table of Comparison

| Feature | Acrylic Light Diffuser | Polypropylene Diffuser |

|---|---|---|

| Material Properties | Rigid, durable, high optical clarity | Flexible, impact-resistant, moderate clarity |

| Light Diffusion Quality | Uniform, soft light distribution | Good diffusion, slightly lower uniformity |

| Heat Resistance | High thermal stability up to 80degC | Moderate heat resistance, up to 60degC |

| UV Resistance | Good UV stability, resists yellowing | Lower UV resistance, may degrade over time |

| Cost | Higher price point | More cost-effective |

| Applications | Indoor lighting, architectural panels | General lighting, outdoor fixtures |

Introduction to Acrylic and Polypropylene Diffusers

Acrylic light diffusers offer superior clarity and durability, providing even light distribution with high resistance to UV exposure and yellowing over time. Polypropylene diffusers are more cost-effective and flexible, with excellent chemical resistance but lower optical clarity compared to acrylic. Both materials serve as effective light diffusing solutions, with acrylic preferred for premium lighting applications and polypropylene suited for budget-conscious or industrial uses.

Material Properties: Acrylic vs Polypropylene

Acrylic diffusers offer superior optical clarity and higher light transmission compared to polypropylene diffusers, making them ideal for applications requiring enhanced brightness and color rendering. Acrylic's rigidity and UV resistance contribute to its durability and long-term performance, while polypropylene is more flexible and resistant to impact but typically has lower light diffusion efficiency. The choice between acrylic and polypropylene diffusers hinges on balancing light quality, material strength, and environmental exposure for optimal lighting design.

Light Transmission Efficiency Comparison

Acrylic light diffusers typically offer higher light transmission efficiency, averaging around 92-94%, compared to polypropylene diffusers which generally transmit about 80-85% of light. The superior clarity and optical properties of acrylic materials contribute to reduced light scattering and enhanced brightness. Polypropylene, while more cost-effective and durable, tends to absorb and diffuse more light, resulting in lower transmission rates.

Durability and Impact Resistance

Acrylic light diffusers offer superior clarity and higher scratch resistance but are more prone to cracking under heavy impact compared to polypropylene diffusers. Polypropylene diffusers excel in impact resistance and flexibility, making them less likely to fracture in harsh environments while providing moderate durability against wear. Choosing between acrylic and polypropylene depends on application needs where acrylic suits aesthetic clarity and polypropylene prioritizes toughness and long-term resilience.

Heat and UV Resistance Analysis

Acrylic light diffusers offer superior heat resistance, maintaining structural integrity and clarity at temperatures up to 80degC, while polypropylene diffusers typically degrade or warp around 60degC. In terms of UV resistance, acrylic excels with enhanced UV stability and color retention over prolonged exposure, whereas polypropylene is prone to yellowing and brittleness due to limited UV protection. These properties make acrylic diffusers more durable and reliable for high-heat, outdoor lighting applications compared to polypropylene alternatives.

Applications in Lighting Fixtures

Acrylic light diffusers offer superior clarity and UV resistance, making them ideal for high-quality lighting fixtures in commercial and residential spaces where consistent light diffusion and durability are critical. Polypropylene diffusers provide cost-effective, lightweight solutions with excellent chemical resistance, often used in budget-friendly or industrial lighting applications where impact resistance and flexibility are prioritized. Both materials influence light diffusion efficiency and fixture longevity, but acrylic's higher optical clarity enhances color rendering and brightness control in sophisticated lighting designs.

Cost Considerations: Acrylic vs Polypropylene

Acrylic light diffusers typically command higher costs due to superior clarity and durability compared to polypropylene diffusers, which are known for their lower price and lightweight properties. Cost considerations often weigh heavily in large-scale lighting projects where polypropylene offers budget-friendly options without significantly compromising diffusion quality. Choosing between acrylic and polypropylene diffusers requires balancing upfront investment against longevity and optical performance to optimize overall project value.

Aesthetic Differences and Design Flexibility

Acrylic light diffusers offer superior clarity and a smooth, glass-like finish that enhances aesthetic appeal in modern lighting designs. Polypropylene diffusers provide a matte, softer texture that can be more forgiving in industrial or utilitarian applications but lack the high-end visual refinement of acrylic. Acrylic's greater design flexibility allows for intricate shapes and vibrant color options, making it ideal for customized and stylish lighting solutions.

Environmental Impact and Recyclability

Acrylic light diffusers offer superior clarity and durability but have a more complex recycling process due to their chemical composition, often requiring specialized facilities. Polypropylene diffusers are more environmentally friendly, being easier to recycle through standard municipal programs and having a lower carbon footprint during production. Choosing polypropylene diffusers can significantly reduce environmental impact by enhancing recyclability and minimizing long-term waste accumulation.

Choosing the Right Diffuser Material for Your Project

Acrylic light diffusers offer superior optical clarity and UV resistance, making them ideal for projects requiring high light transmission and durability under sunlight exposure. Polypropylene diffusers provide excellent impact resistance and chemical stability, suited for applications needing robust performance in harsh environments. Selecting the right diffuser material depends on balancing clarity and durability requirements with environmental factors and budget constraints.

Acrylic Light Diffuser vs Polypropylene Diffuser Infographic

materialdif.com

materialdif.com